|

|||

|

|

|||

|

Page Title:

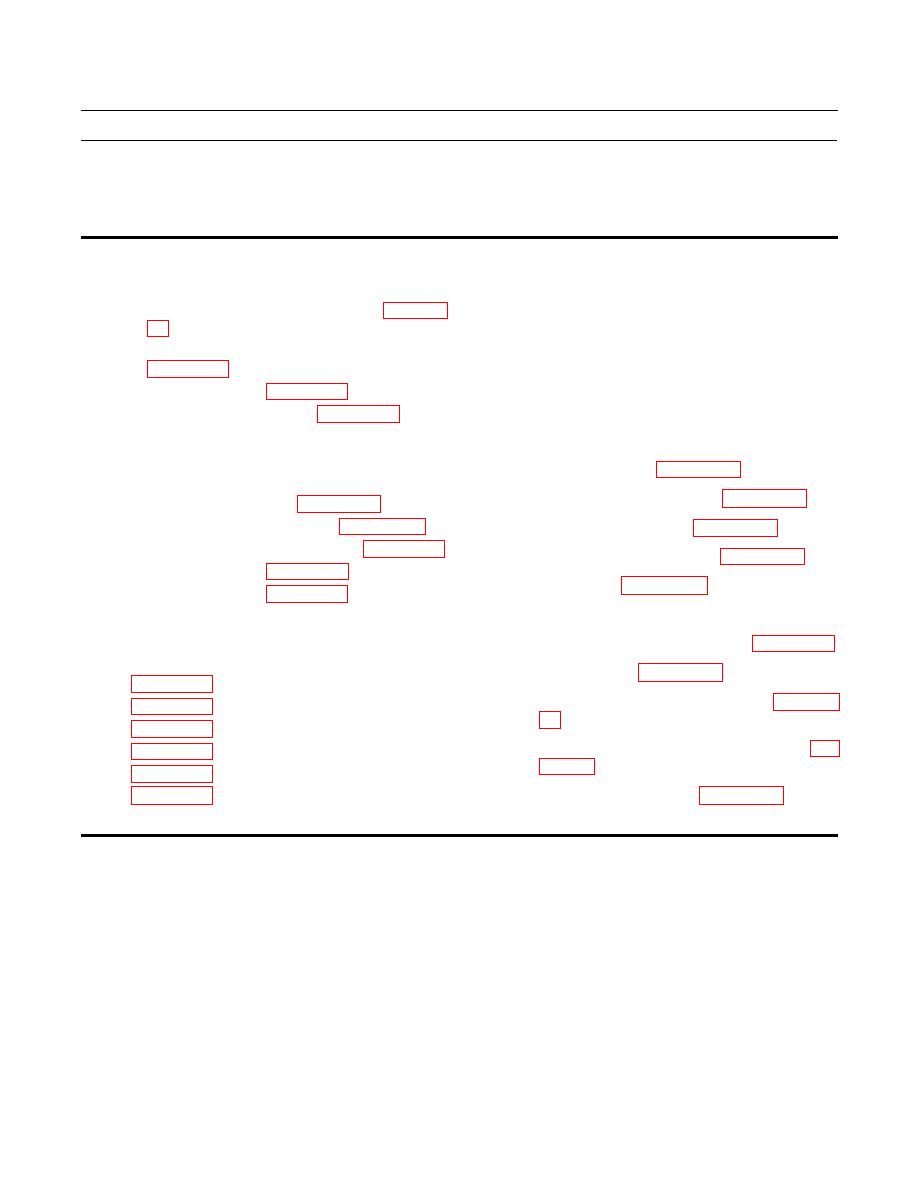

TRANSMISSION ASSEMBLY REPLACEMENT |

|

||

| ||||||||||

|

|

TM 5-2410-233-23

TRANSMISSION ASSEMBLY REPLACEMENT

THIS WORK PACKAGE COVERS

Removal, Installation

INITIAL SETUP

Personnel Required

Tools and Special Tools

Tool kit, general mechanic's (Item 112, WP 0185

Three

Equipment Condition

Shop equipment, general purpose repair (Item 97,

Machine parked on level surface (TM 5-2410-233-

Link, lifting (Item 44, WP 0185 00)

10)

Stand, transmission (Item 107, WP 0185 00)

Battery disconnect switch in OFF position (TM 5-

Lifting equipment, 2,000 lb capacity

2410-233-10)

Bolt 3/4 -10 x 1-1/2 in.

Floor plates removed (WP 0135 00)

Materials/Parts

Transmission system oil drained (WP 0086 00)

Cap set, protective (Item 2, WP 0184 00)

Compound, silicone, RTV (Item 9, WP 0184 00)

Transmission guard opened (WP 0129 00)

Oil, lubricating (Item 22, 23, 24 or 25, WP 0184 00)

Driveshaft and U-joint removed (WP 0106 00)

Rag, wiping (Item 28, WP 0184 00)

ROPS removed (WP 0131 00)

Tag, marker (Item 35, WP 0184 00)

Winterized cab removed, if equipped

Gasket (7)

Lockwasher (6)

Seat and seat base assembly removed (WP 0137 00)

References

Batteries removed (WP 0081 00)

Transmission selector linkage removed (WP 0083

Steering clutch levers and linkage removed (WP

Winch removed, if equipped (WP 0139 00)

REMOVAL

CAUTION

Wipe area clean around all hydraulic connections to be opened during removal. Cap oil lines and plug

openings after removing lines. Contamination of transmission could result in premature failure.

NOTE

Tag wires and lines as needed, to ensure correct installation.

Use a suitable container to catch any oil that may drain from system. Dispose of oil IAW local

policy and ordinances. Ensure all spills are cleaned up.

For machines with ripper, ensure divertor manifold is clear of transmission.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |