|

|||

|

|

|||

|

Page Title:

Table 5. Winch Troubleshooting Procedures. |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

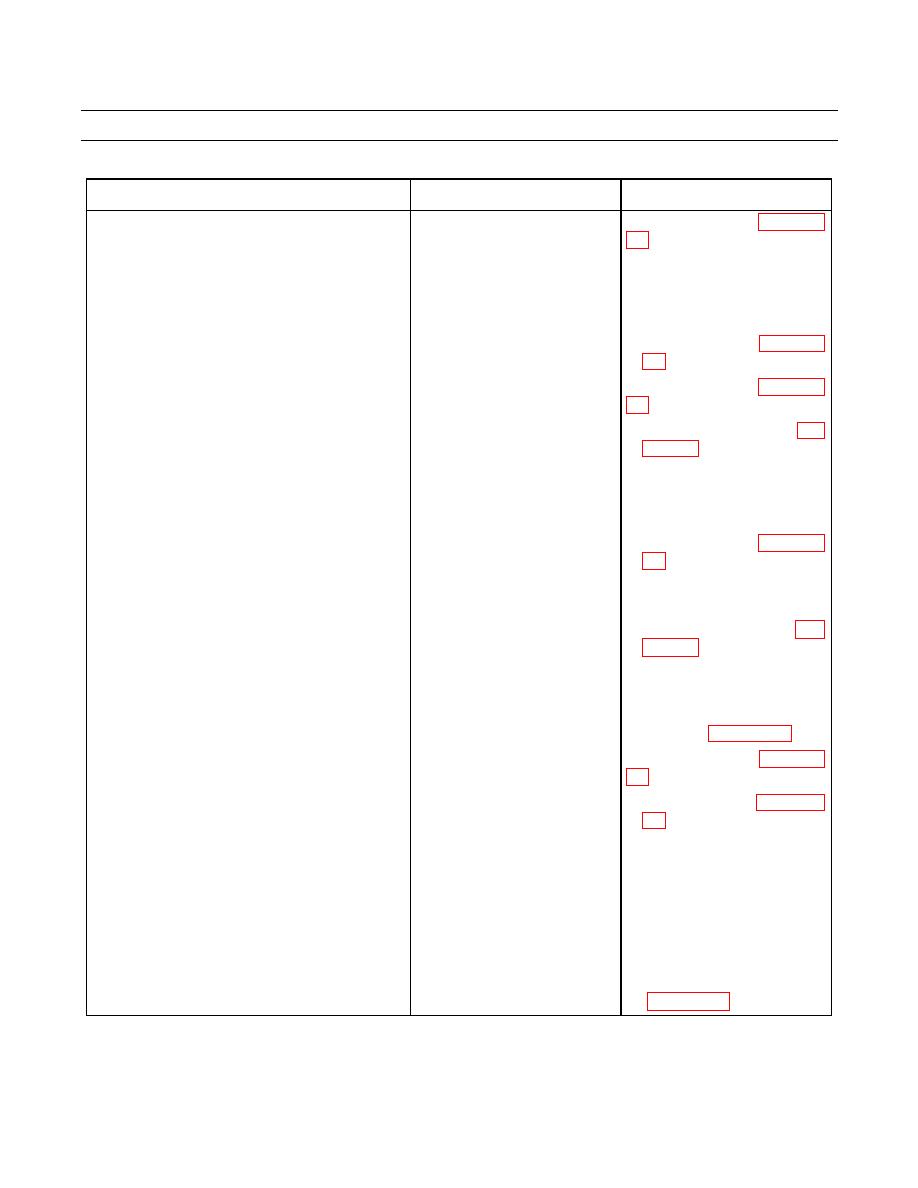

Table 5. Winch Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

Winch Does Not Operate.

1.

Check winch reservoir for

Fill to proper level (WP 0179

proper oil level.

2.

Check winch system oil

1. Tighten loose fittings.

lines and connections for

damage and leaks.

2. Replace damaged or leaking

lines and fittings (WP 0190

3.

Check

winch

control

Adjust if necessary (WP 0182

linkage adjustment.

1. Reconnect control cable (WP

4.

Check winch control cables

for bends, kinks, breaks or if

they are disconnected from

control lever bellcrank or

control valve.

2. If control cable(s) is

damaged, replace (WP 0183

5.

Inspect winch control valve

1. Tighten loose fittings.

for damage and leaks.

2. Replace control valve (WP

6.

Check winch gear pump for

1. Tighten loose fittings.

leaks and overheating.

2. Replace gear pump

if

necessary (WP 0189 00).

7.

Check for broken winch

Replace drive shaft (WP 0181

drive shaft.

1. Reconnect cable (WP 0183

2.

Winch Operates in One Direction Only.

1.

Check for damaged, kinked,

broken or disconnected

winch control cables or rod

end.

2. If control cable is damaged,

replace (WP 0183).

1. Tighten loose fittings.

2.

Inspect winch control valve

and valve connections for

damage and leaks.

2. Replace winch control valve

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |