|

|||

|

|

|||

|

Page Title:

Table 4. Hydraulic System Troubleshooting Procedures - Continued. |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

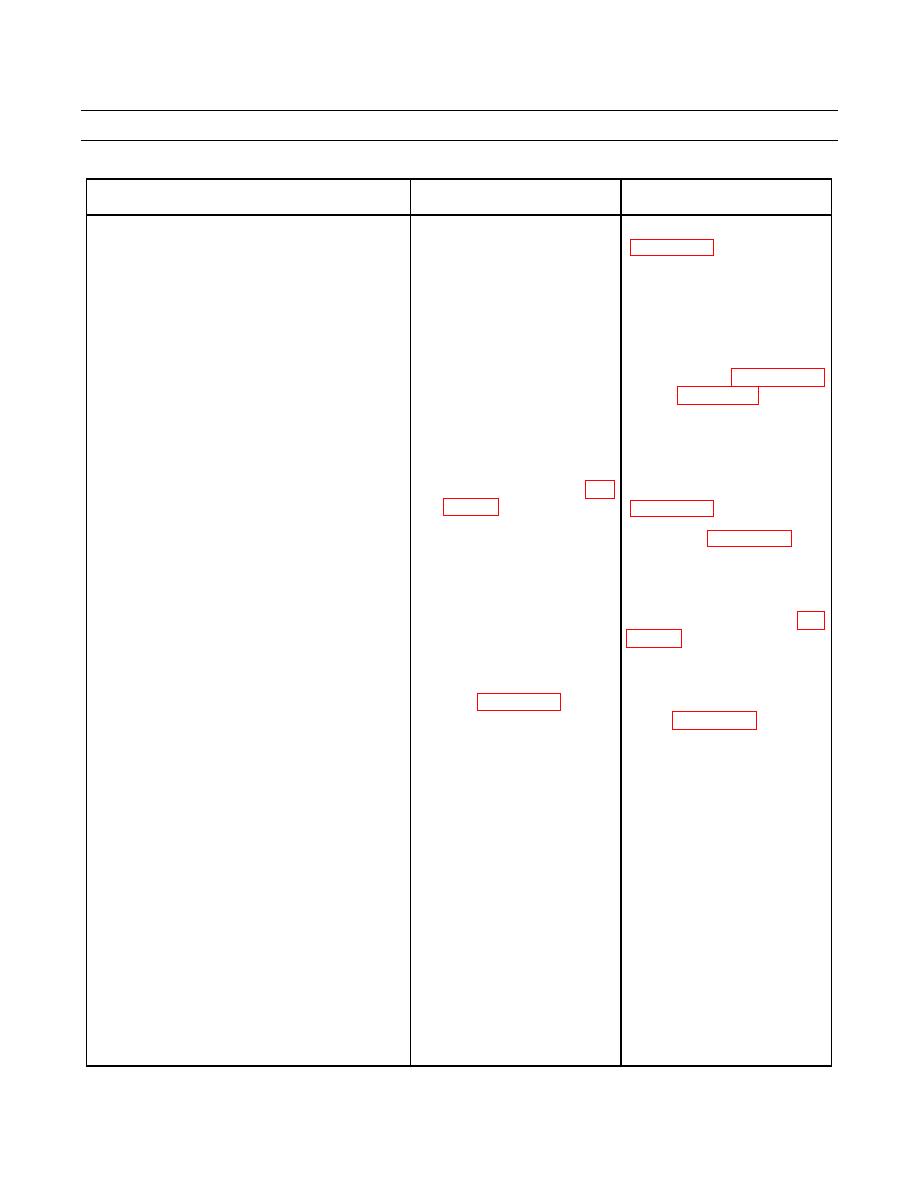

Table 4. Hydraulic System Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Add or replace oil as required

6.

Blade Tilt or Ripper Lift Circuit is Slow or

1.

Check hydraulic tank for

Does Not Move.

correct oil level. Ensure

tank is filled with correct

viscosity oil.

2.

Carefully check system for

Repair or

replace

leaking

leakage.

component.

Tighten or replace loose or

3.

Check hydraulic lines,

hoses and fittings for signs

damaged lines (WP 0214 00

of leaks or damage.

through WP 0216 00).

4.

Check pilot

lines

for

Repair or replace pilot line.

restrictions.

5.

Perform hydraulic system

Adjust, repair or replace affected

flow tests for circuit (WP

component IAW test results

Replace line (WP 0212 00).

1.

Inspect pilot line between

7.

Ripper Moves Very Slowly/No Down

pilot valves and blade

Pressure in Lift Circuit (Blade Tilt Circuit

control valve shuttle valve

OK).

for restriction.

Replace blade control valve (WP

2.

There may be internal

damage to blade control

valve.

1.

Perform hydraulic system

Adjust, repair or repair affected

8.

Hydraulic Oil is Overheating (Indicated by

tests (WP 0227 00).

Blown Oil Seals, Decreased Life of

compnent(s) as directed by test

Components).

results (WP 0227 00).

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |