|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

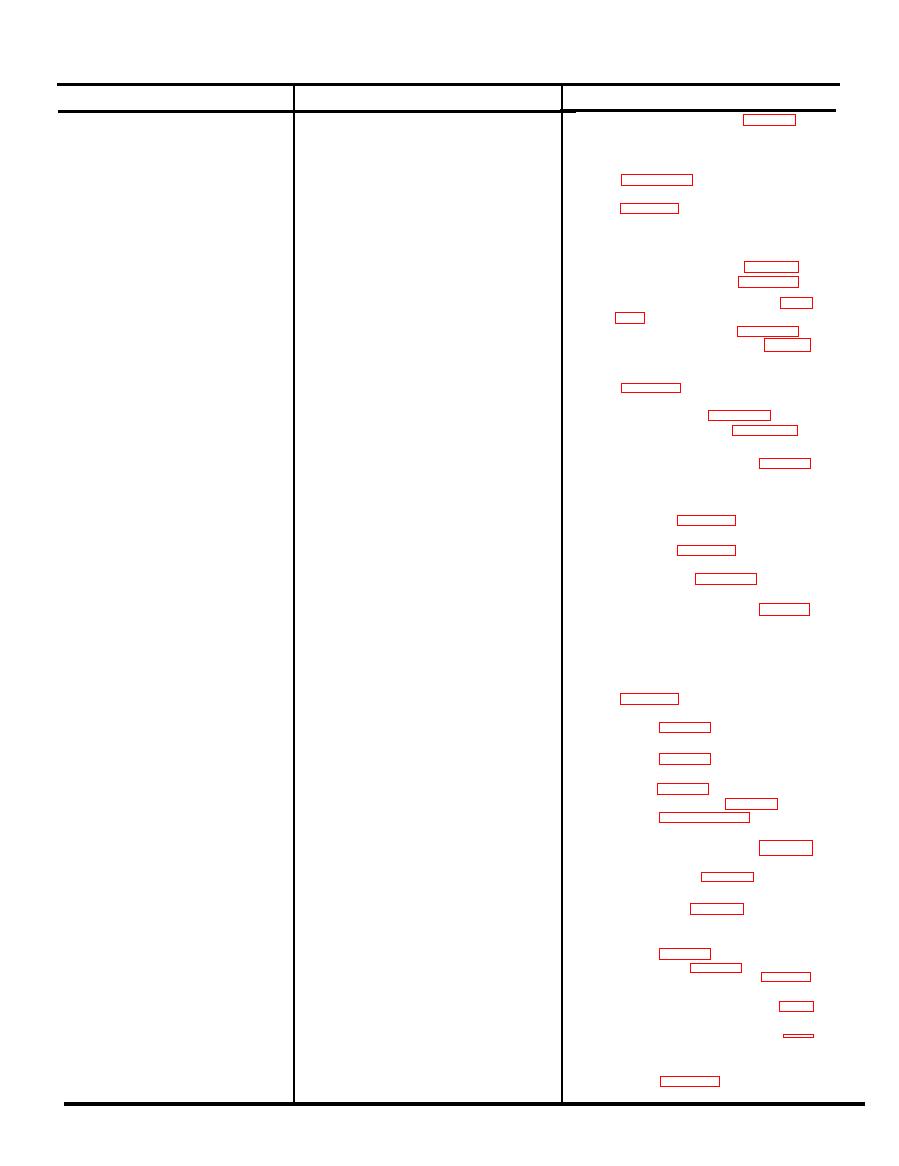

Chart 2-1. Troubleshooting-Continued

Corrective Action

Probable Cause

Malfunction

4. Excessive engine vibration

a. Loose, worn, or defective engine

and tighten all mountin bolts

mounts

securely.

b. T i g h t e n p u l l e y m o u n t i n g b o l t

b. Loose pulley and damper

c. Replace defective pulley or damper

c. Defective pulley or damper

d. Refer to (1) above.

d. Misfiring

e. R e m o v e f a n b e l t s f o r s h o r t

e. Unbalanced fan

duration. If vibration is no longer

evident, replace fan (para 5-4).

5. Engine smokes

a. Worn piston rings

b. Defective valves

6. Engine knocks excessively

a. Broken valve spring

33).

c. Tighten bolts or replace bearing

c. Loose connection rod or main

bearing bolts or worn bearings

7 . Low or no lubricating oil pressure

a. Worn main bearing

indication

c. R e p a i r o r r e p l a c e a d e f e c t i v e

c. Pressure regulating valve worn or

pressure regulating valve (para 5-

stuck thus restricting the flow of

24.

oil

D i s a s s e m b l e starter and replace

8. Starter will not crank engine

Armature burned out

armature (para 5-21).

a. Disassemble generator and replace

9. Generator not charging

a. Generator

shorted

armature (para 5-20).

b. R e p l a c e a d e f e c t i v e g e n e r a t o r

b. Brush spring tension too low

brush spring (para 5-20).

10. Fully charged battery and a high

a. Short circuit in generator

charging rate

or replace as necessary (para 5-

20).

b. Adjust (Refer to TM 5-2410-233-

20).

properly

a. Refer to TM 5-2410-233-20.

11. Transmission does not operate in

a. Leakage in external lines

b. C h e c k p r e s s u r e s a t t e s t p o i n t s

b. Leakage within transmission

any speed

c. Remove valve for inspection and

c. Pressure relief valve in hydraulic

repair (para 6-4).

control valve stuck open.

d. Remove valve for inspection and

d. Check valve stuck in bore

repair (para 6-8).

e. Remove valve for inspection and

e. Differential valve sticking closed

repair (para 6-4).

f. Safety valve improperly adjusted

a. I n s p e c t d i r e c t i o n a l v a l v e a n d

1 2 . Tractor remains in gear with

a. Obstruction preventing directional

remove any obstruction (para 6-

clutch from releasing.

selector valve in neutral

3).

b. Control linkage improperly ad-

justed

c. Speed and safety valve improperly

adjusted

13. Ripper will not raise

a. Defective relief valve in hydraulic

a. Remove valve for inspection and

repair (para 4-5).

control

b. Improper relief valve setting

Remove and inspect valve (para 4-

Defective relief valve in hydraulic

14. Ripper will not lower

4).

control

Inspect and repair cylinder (para

Worn cylinder piston rod packing

15. Ripper will not stay in ground

4-10).

and seals

a. Replace broken brake spring (para

16. Winch brake not holding

a. Broken brake spring

3-14).

properly

b. Remove valve for inspection and

b. Sticking or damaged piston in

repair (para 3-13).

winch control valve

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |