|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

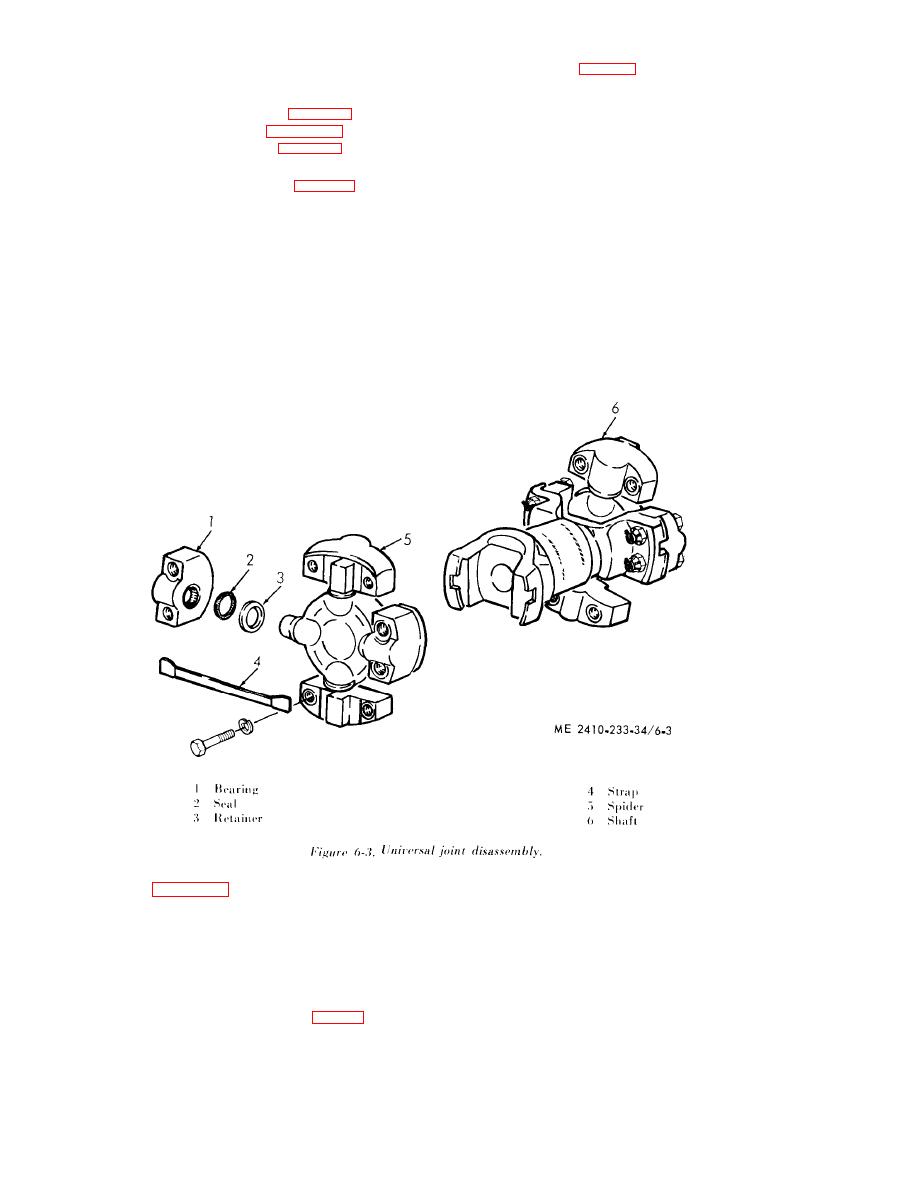

b. Disassembly (fig. 6-3).

6-2. Universal Joint

secure

the

(1) Remove the bolts

which

a. Removal.

b e a r i n g s to the spiders.

(1) Remove the floor plates (para 2-8a) and

( 2 ) Remove the strap (4) from bearings (1).

the brake pedals and support (para 6-30).

(3) Remove the bearing (1), seal (2) and

( 2 ) Remove oil supply line (fig. 2-33), (sheet

retainer (3) from the spider (5).

2 ) and oil pressure line.

c.

Inspection.

( 3 ) Rotate the universal joint (fig. 2-31, sheet

(1) Inspect the spider journal bearing surfaces

4 of 6) as necessary and remove the bolts securing

f o r roughness or needle bearing grooves.

the bearing caps to the transmission input shaft

(2) Carefully inspect each bearing for wear

f l a n g e and torque divider output shaft flange.

a n d for broken or missing needle bearings.

( 4 ) Pry the universal joint bearing caps loose

( 3 ) Replace the spider and bearing assembly

f r o m each flange and remove the universal joint.

wear.

NOTE

Do

not

cut

the

metal

straps

securing

the

bearing

( 4 ) Light brineling of the spider bearing area

caps

to

the

spider.

If

they

are

cut

or

missing,

tem-

is not harmful.

porarily fasten the bearing caps to the wniversal joint to

d. Reassembly and Installation. Reassemble the

prevent

them

from

sliding

off

or

dirt

entering

the

universal joint in the reverse order of disassembly.

bearings.

stator or reactionary member (12) which directs the

Torque

Divider

o i l to rotate the turbine (10). Since the turbine is

a. General (fig. 6-1). The torque divider is

mounted in the torque divider housing (1). It pilots

s p l i n e d to the same hub) as the ring gear (4), the

into the diesel engine flywheel (3) and is supported

torque, is transferred through the planet carrier (8)

in the housing (1) by a bearing mounted in a carrier

to the output shaft (7). A lesser amount of torque is

t r a n s m i t t e d from the engine flywheel (3) through

(11).

the sun gear (6) and planet carrier (8) to the output

b. O p e r a t i o n .

shaft (7).

( 1 ) The torque divider is driven by the diesel

emgine through a rotating housing (2, fig. 6-1) and

(2) The planetary system is composed of a sun

sun gear (6) to direct the torque output of the

gear (6) that turns with the diesel engine flywheel

engine through two separate paths. Most of the

(3), a planet carrier (8) which is splined to the

t o r q u e is transmitted by the rotating housing (2)

o u t p u t shaft (7) and supports the planet gears (9)

and impeller (5) through a medium of oil to the

t h a t mesh with the ring gear (4).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |