|

|||

|

|

|||

|

Page Title:

Section Ill. GENERAL MAINTENANCE |

|

||

| ||||||||||

|

|

Chart

2-1.

Trouble-Continued

Probable Cause

Corrective Action

Malfunction

c.

Remove

valve

for

inspection

and

c.

Worn

poppet

on

valve

selector

repair

spool

a.

Remove

winch

for

inspection

and

17.

Winch

clutch

pressure

low

a. Broken seal ring on bevel gearshaft

repalce broken seal ring (para 3-

14).

b.

Damaged

preformed

packing

in

b.

Remove

winch

for

inspection

and

clutch

pack

replace

preformed

packing

Section Ill. GENERAL MAINTENANCE

General

This section provides direct support and general

s u p p o r t maintenance personnel with general repair

instructions applicable to the Caterpillar D-7F

tractor. T h e f o l l o w i n g i n s t r u c t i o n s w i l l p r o v e

helpful to disassemble and assemble the tractor

components.

Genera]

Instructions

a . Cleanliness.

(1) Whenever hydraulic, fuel, lubricating oil or

air lines are disconnected, clean the point of

disconnection and the adjacent area. As soon as the

disconnection is made, cap, plug or tape the line or

c . Disassembly and Assembly. W h e n a s s e m b l i n g

o p e n i n g to prevent entry of foreign material. The

a machine, complete each step in turn. Do not

same recommendations for cleaning and covering

partially assemble one part and start assembling

a p p l y when access covers or inspection plates are

other part. Make all adjustments as

some

removed.

recommended. Always check the job after it is

(2) Clean and inspect all parts. Be sure all

completed to see nothing has been overlooked.

passages and holes are open. Cover all parts to keep

d . Service Tools.

them clean. Be sure parts are clean when installed.

(1) Puller assembly (2 or 3 arm). Two or three

Leave new parts in their containers until ready for

arm puller assemblies (figs. 2-3 and 2-4) can be

assembly.

used to remove gears,

bearing

cages,

hubs,

b. Removal and Installation.

b e a r i n g s , shafts, etc.

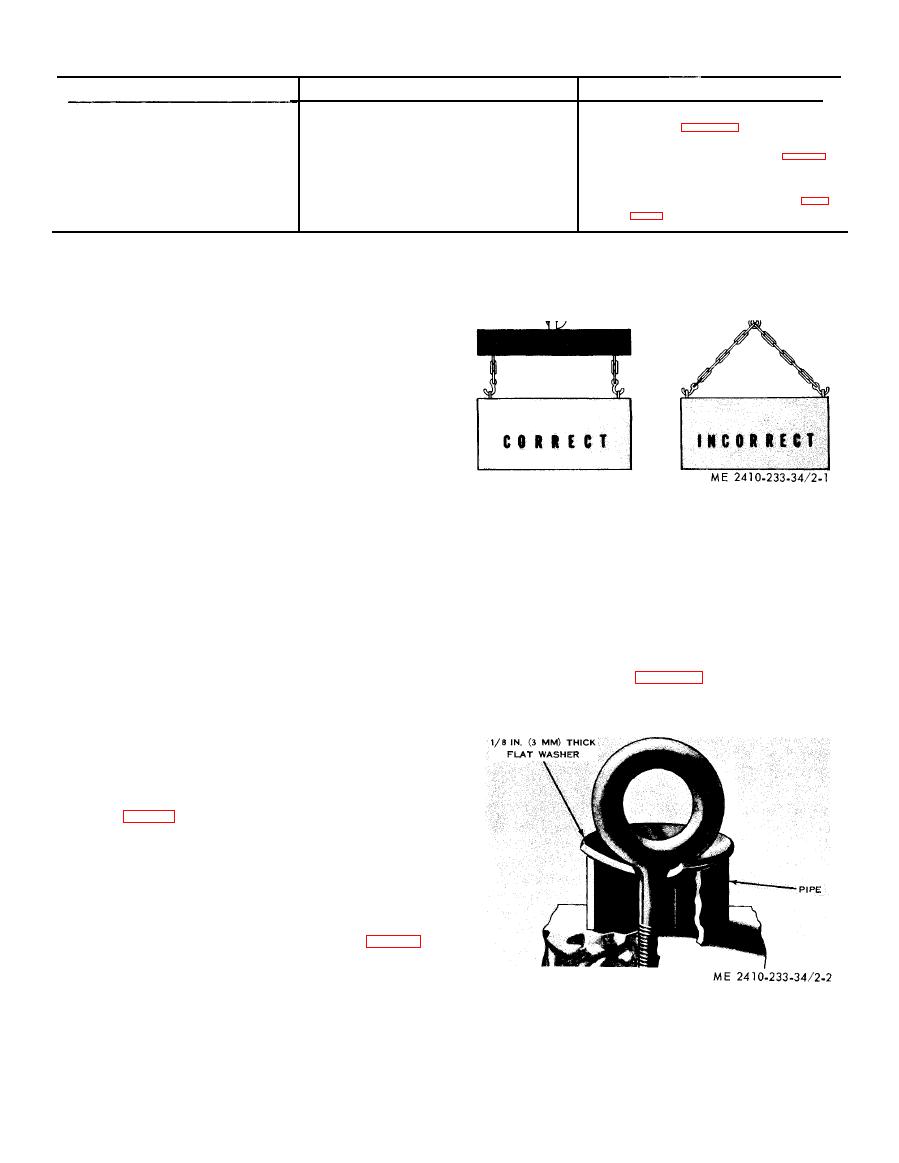

(1) Unless otherwise specified, all removals

s h o u l d be accomplished using an adjustable lifting

b e a m . All supporting members (chains and cables)

s h o u l d be parallel to each other and as near per-

pendicular as possible to the top of the object being

lifted (fig. 2-1).

(2) When it is necessary to remove a com-

ponent on an angle, remember that the capacity of

an eyebolt diminishes as the angle between the

supporting members and the object becomes less

than 90. Eyebolts and brackets should never be

bent and should only have stress in tension. A

length of pipe and a washer can be used (fig. 2-2),

t o help relieve these stresses on eyebolts.

( 3 ) Some removals require the use of lifting

fixtures to obtain proper balance and to provide

safe handling.

(4) If a part resists removal, check to be

c e r t a i n all nuts and bolts have been removed and

t h a t an adjacent part is not interfering.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |