|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

f. Cleaning. Clean all parts with cleaning solvent

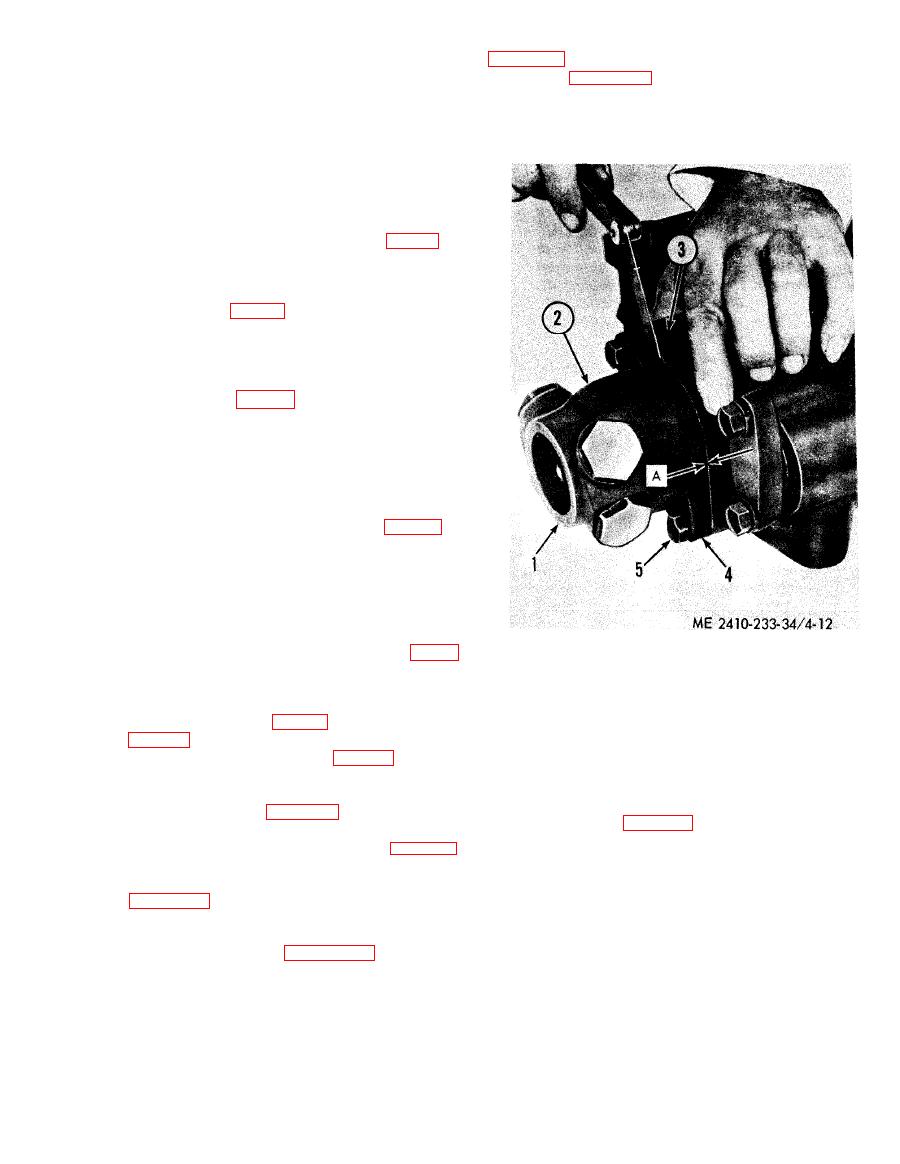

spacer (3), figure 4-12, tight against the valve body

(Fed. Spec. P-D-680) and dry with clean com-

and measure clearance (A) between housing (2)

pressed air or wipe dry using a lint-free cloth.

g. Inspection and Repair.

and spacer (3) with a thickness gage. Install shims

(4) with a thickness equal to this measurement.

(1) Inspect valve body and spool for nicks,

burrs, pitting, and wear. Light scratches or a light

grey wear appearance are not harmful to the valve.

Examine the valve land edges for wear. If wear or

damage exists, the complete valve assembly must

be replaced.

(2) Inspect detent plug assemblies (2, fig. 4-5)

for weak or damaged springs and worn or damaged

balls. Replace as required.

(3) Inspect the check valve for weak or

damaged spring (4, fig. 4-7) and free movement of

valve in bore. Inspect valve chamfered seating

surface and valve seat in body (7), for nicks, burrs

and proper contact. Replace as required.

(4) Inspect the make-up valves for weak or

damaged springs (3, fig. 4-9) and free movement of

valve (4) in bores. Inspect valve chamfered seating

surfaces and valve seats in body (5) for nicks,

burrs, and 100 percent contact. Finger pressure

against the face of the valve should open it and the

spring should return the valve to closed position.

Replace defective springs or valves.

(5) Inspect control shaft bearings (6, fig. 4-11)

for corrosion, roughness, and wear. Replace

corroded, rough, or worn bearings.

(6) Replace control shaft oil seal (7). Examine

control shaft for wear due to seal contact. Replace

shaft if deeply grooved.

h. Reassembly.

(1) Reassemble the control lever using figure

1

Spool

4-11 as a guide. Install the seal (7), with the lip

2

Housing

3

Spacer

toward bearings (6) and the metal case flush with

4

Shims

the outside face of the housing (5). Position and

5

Bolts (2)

install the outer lever (4, fig. 4-10) on control lever

A

Clearance to be measured

(3, fig. 4-11) until it is snug but not tight against

washer (1), then tighten bolt (3, fig. 4-10). Check

for binding.

i. Installation. Reverse removal procedure,

(2) Reassemble make-up valves and springs.

install bulldozer control valve and torque bolts (3),

Torque bolts (1) and (6), Figure 4-8, to 60 2 ft-

(7), (8) and (12), figure 4-4, to 60 2 ft-lbs.

lbs. Torque bolts (4) to 60 2 ft-lbs.

(3) Reassemble the check valve using figure 4-

7 as a guide. Install valve in housing.

a. General. The bulldozer relief valve ((1), fig. 4-

(4) Reassemble and install the control valve

13) mounted on the bottom plate of the hydraulic

using figures 4-5 and 4-6 as guides. To obtain the

tank, prevents excessive pressures from being

correct thickness of shims required, assemble and

imposed on the large section of the two-section

install the valve spool. Install housing without

pump and other components of the bulldozer

shims. Tighten bolts (5), figure 4-12, until the

circuit.

shoulder in the housing just contacts retainer (2),

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |