|

|||

|

|

|||

|

Page Title:

Table 1. Engine Troubleshooting Procedures - Continued. |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

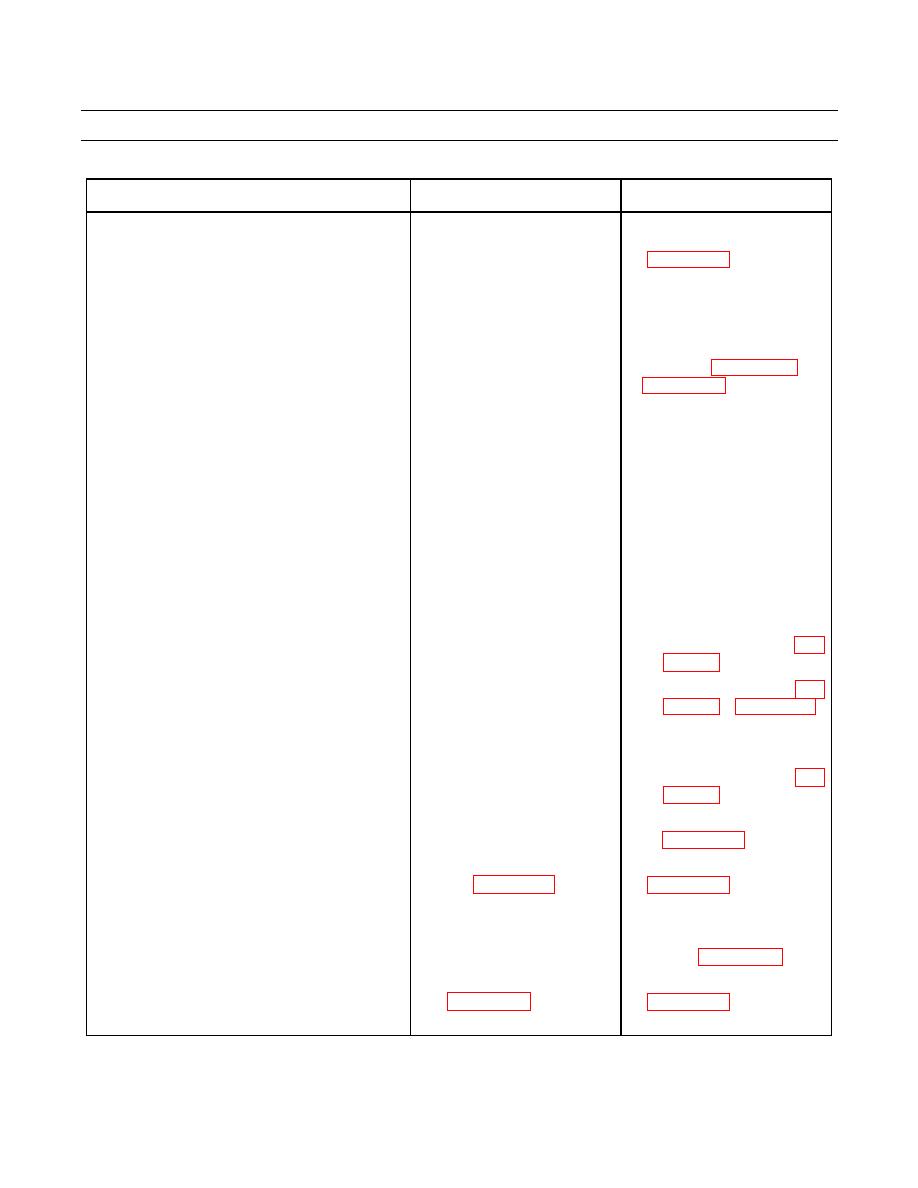

Table 1. Engine Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

9.

Excessive Engine Vibration - Continued.

b. Operate engine at rpm

1. If vibration is not noticeable,

where vibration occurred.

replace fan drive assembly

2. If vibration is noticeable, go

to step 5.

5.

Inspect for loose engine

1. If supports are loose because

mounting supports.

of wear or damage, replace

support(s) (WP 0022 00 and

2. If mounting supports are not

damaged or worn, but are

loose, tighten mounting

supports-to-fram capscrews

to 325 lb-ft (441 Nm).

Securely

tighten

front

supports-to-engine and rear

supports-to-flywheel housing

capscrews.

If incorrect fuel was put in,

10. Engine Knocks (Fuel Knock).

1.

Check with operator to

determine if fuel tank was

perform the following tasks:

filled with correct fuel.

a. Drain fuel system (WP

b. Replace fuel filters (WP

c. Fill fuel tank with correct

fuel (TM 5-2410-237-10).

d. Prime fuel system (WP

2.

Check fuel injection lines

Bleed air from fuel injection

for air.

lines (WP 0041 00).

3.

Perform cylinder balance

1. Replace defective nozzle

test (WP 0043 00).

2. If nozzle is operating

properly,

replace

fuel

injection pump for that

cylinder (WP 0055 00).

4.

Check fuel injection timing

3. Adjust timing, if necessary

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |