|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(12) Assemble housing in reverse order of

disassembly and bolt the two housings together.

(13) Valves and plungers can be removed from

c o n t r o l valve housing (2, fig. 6-105) by removing

rings (1) and plugs (3).

(14)

Inspect

preformed

packings

on

plugs

before assembly.

d. Inspection and Repair.

(1) Inspect the valve housing and valves for

nicks, burrs, scoring, pitting, and wear. Light

scratches or a light grey wear appearance are not

h a r m f u l to the valve. Examine the valve land edges

for wear. If wear or damage exists, the complete

valve assembly must be replaced.

(2) Inspect valve bushings for damage and

wear. Replace as required.

(3) Inspect the valve springs for cracks,

breaks, distortion, or weak condition. Replace

defective springs.

(4) Inspect control lever shafts and bearings

for corrosion, roughness and wear. Replace

shaft.

corroded, rough, or worn shafts and bearings.

(5) Install control lever shaft seals with the lip

facing inward.

( 6 ) Inspect the pressure relief valve for nicks,

b u r n s , scoring, and proper operation. Relief valve

should bypass at 350 to 400 psi pressure. Replace a

defective relief valve.

e. Adjustment. Adjust the steering clutch control

linkage as instructed in TM 5-2410-233-20.

a. Removal and Installation.

(1) Drain the oil from the transmission,

steering clutch compartment, and bevel gear

compartment. Refer to TM 5-2410-233-20.

( 2 ) Remove the seat frame (para 2-9) and the

fuel tank (para 5-14).

(3) Remove the steering clutch hydraulic

control (para 6-17), steering clutches (para 6-15)

and the steering clutch driving hubs, (para 6-16).

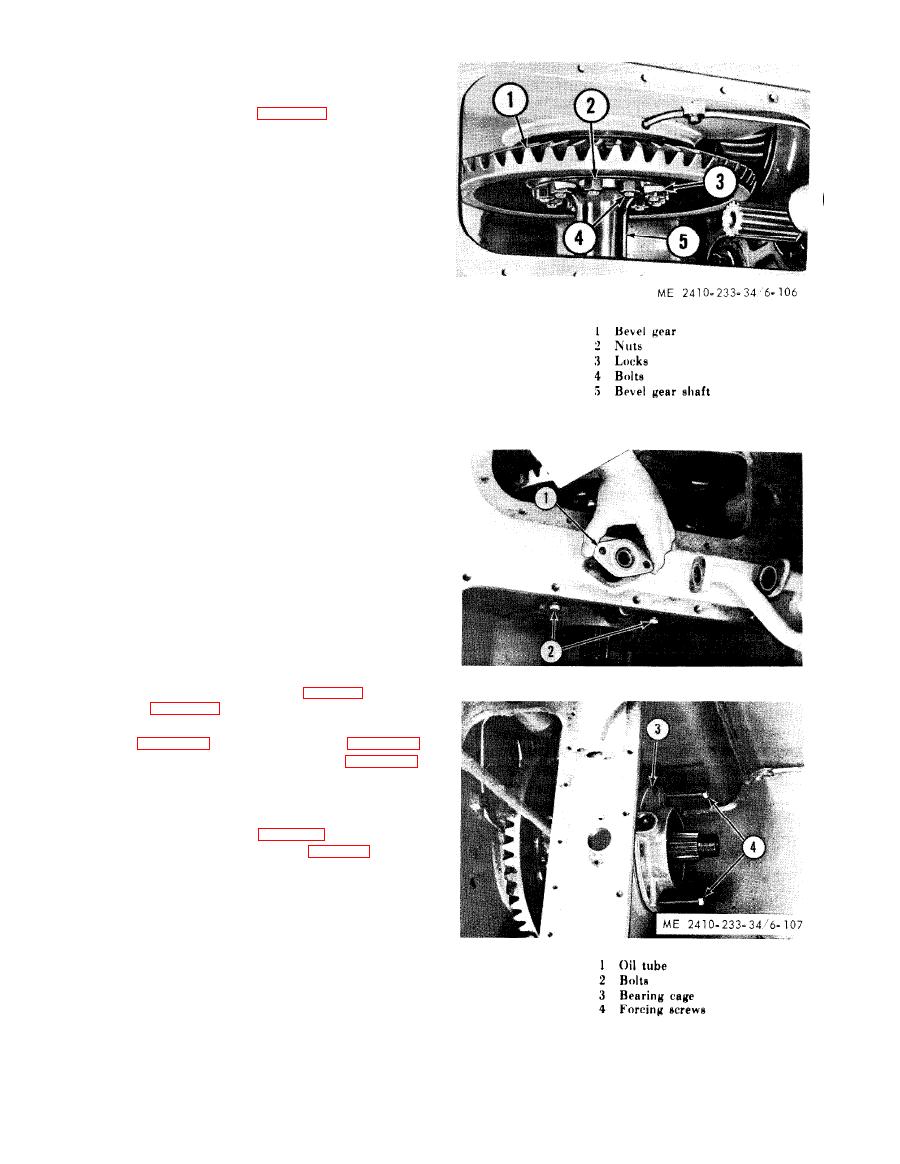

( 4 ) Remove bevel gear compartment plate. At

i n s t a l l a t i o n , apply liquid gasket to bevel gear case

and tighten bolts to 45 3 lb-ft.

( 5 ) Remove nuts (2, fig. 6-106) and locks (3).

(6) Remove oil tube (1, fig. 6-107). At in-

stallation apply liquid gasket to bevel gear case

under tube flange.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |