|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

b r e a k s , and worn lug recesses. Repair or replace as

dictated by the extent of damage.

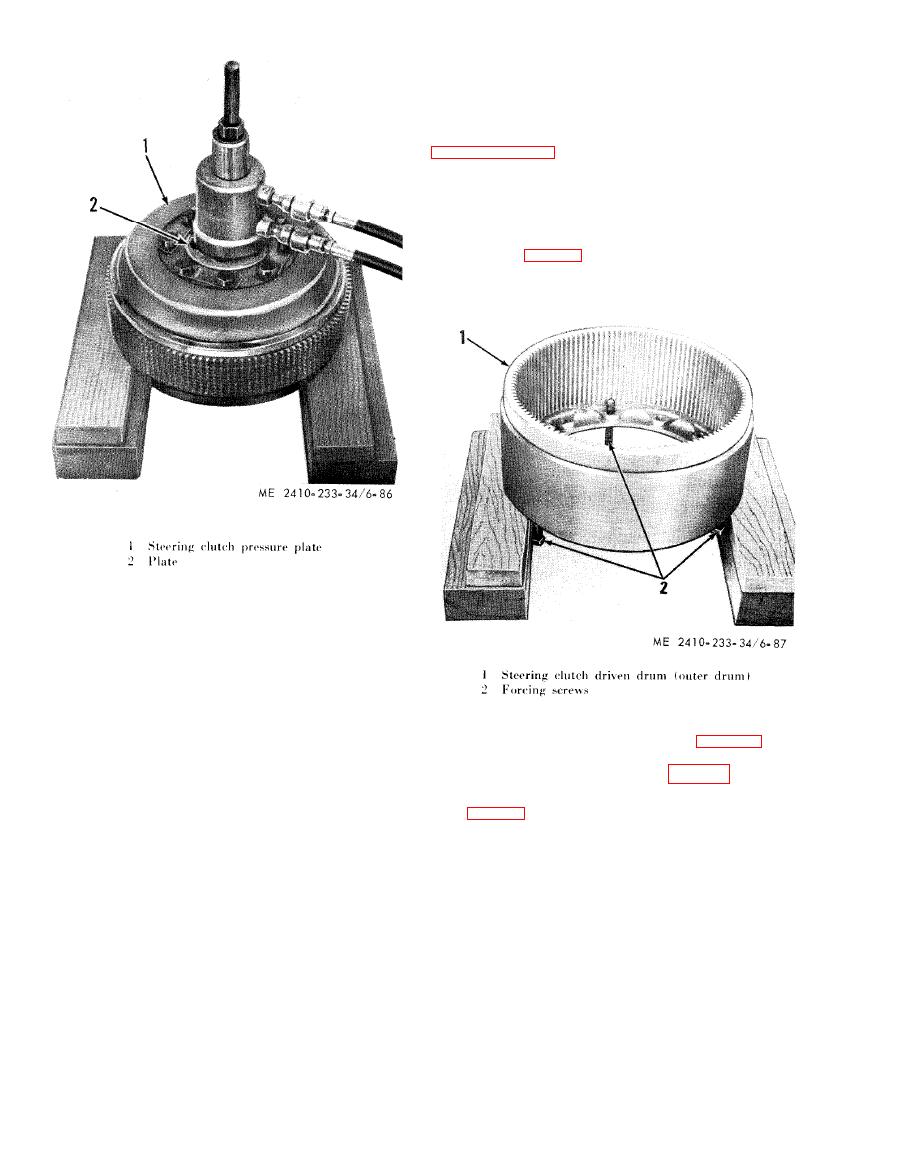

(5) Inspect the clutch outer drum for cracks,

breaks, and worn splines. Repair or replace as

dictated by the extent of damage. Refer to

surface.

e. Assembly.

NOTE

To prevent the f i r s t c l u t c h a s s e m b l y f r o m

dropping below the end of the splines on the outer

forcing screws (2) in the bolting flange of the outer

drum, until they touch the splines.

d. Inspection and Repair.

(1) Inspect the clutch disks for damage and

wear. The clutch disk stack height of 10 disk

assemblies and 9 disks (new) is 2.536 to 2.802

inches. The minimum clutch disk stack height of 10

d i s k assemblies and 9 disks (worn) is 2.356 inches.

R e p l a c e the disks and / or disk assemblies if worn

excessively. Replace disk assemblies which have:

(1) Place the outer drum (1, fig. 6-87) on

( a ) Chipping on the edge of the disk.

b l o c k s as a guide to assemble the disc assemblies

(b) Cracks at tbe root of any of the teeth.

and discs onto the inner drum (1, fig. 6-89).

(c) W o r n t e e t h o n l y w h e n w e a r h a s o b -

( 2 ) Install two 5 / 8 inch 11 (NC) guide pins

viously changed tooth contour.

(2, fig. 6-88) into the clutch spring retainer (6).

(d) Excessive foreign material imbedded in

( 3 ) Insert the bolt through the plate and place

the face. Replace warped disks.

the retainer on the plate and over the bolt. Place

( 2 ) Inspect the clutch inner and outer springs

this assembly into the outer drum on blocks about 2

for damage, distortion, and proper tension. The

inches lower than the outer drum.

outer clutch springs should exert 286 to 316

(4) Insert the clutch spring sleeves (5) into the

pounds of force when compressed to 3.90 inches.

s m a l l e r clutch springs (4), and then place the small

The inner clutch springs should exert 185 to 205

springs and sleeves into the large clutch springs (3).

pounds of force when compressed to 3.71 inches.

(5) Place the springs and sleeves over the

Replace damaged, distorted, or weak clutch

bosses on the retainer.

springs.

(3) Inspect the clutch spring retaining bolts,

s l e e v e s , and retainer for damage and wear. Replace

defective parts as required.

(4) Inspect the clutch inner drum for cracks,

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |