|

|||

|

|

|||

|

Page Title:

Section IX. OIL PAN AND OIL PUMP |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

Section IX. OIL PAN AND OIL PUMP

6-42. General

a. Oil from the oil pan sump is forced through

the pressure type lubrication system by the rotor-

type oil pump. A spring loaded relief valve in the

pump directs excess oil back to the intake side of

the pump.

b. A full-flow disposable filter element filters

the entire output of the pump before the oil enters

the engine. A by-pass valve permits flow around

the filter if it becomes clogged.

c. From the filter, oil flows into the main oil

gallery. From this gallery oil is supplied to the

camshaft and main bearings, to each hydraulic

lifter, to the crankshaft and connecting rods, and

the timing gears. A drilled passage in the block

supplies oil to the distributor shaft, and the valve

train is lubricated by oil from the lifter chamber

passing upward through the pushrods.

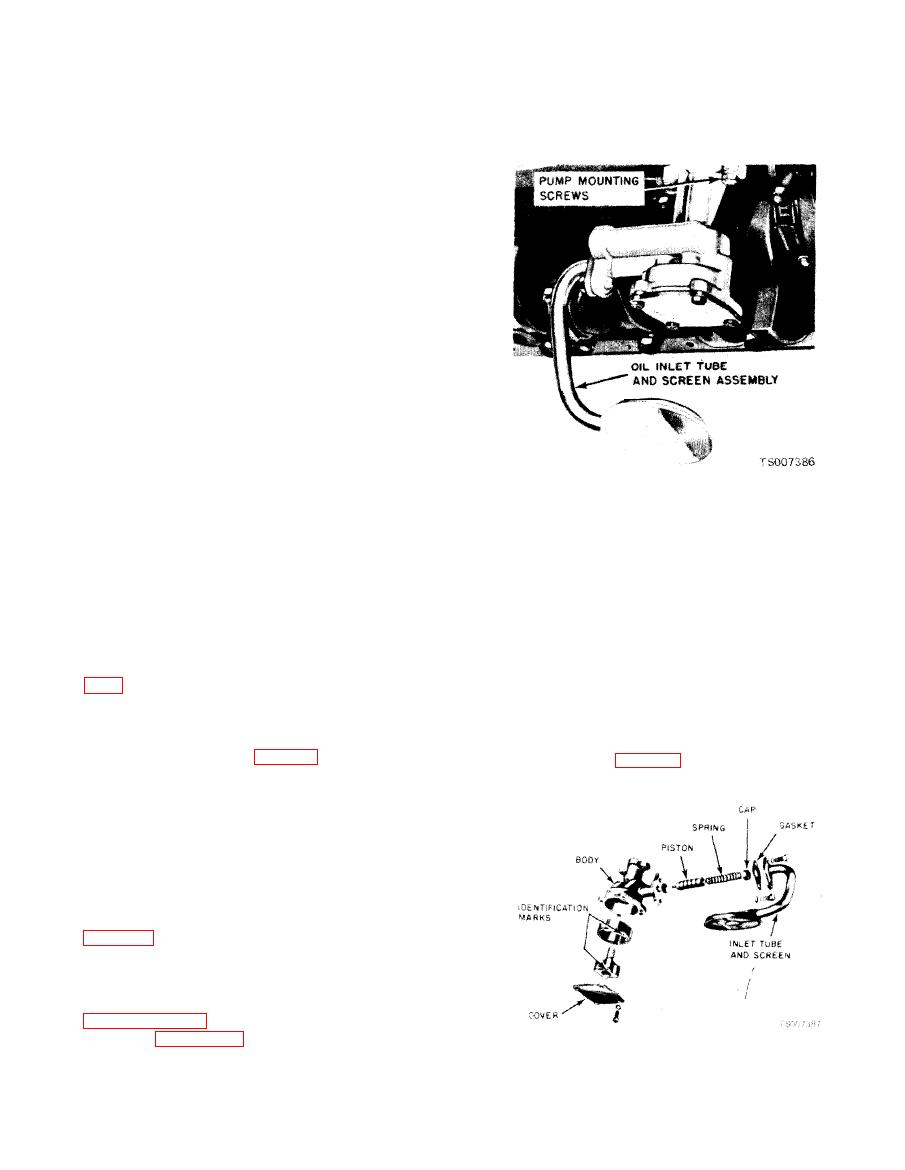

a. Removal.

(1) Drain the crankcase.

(2) Remove the oil pump attaching screws

(2) Remove the oil pan attaching screws and

and remove the pump from the cylinder block.

remove the oil pan,

b. Installation.

b. Installation.

(1) Prime the oil pump by filling the inlet

(1) Clean the gasket surfaces of the oil pump,

opening with oil and rotate the pump shaft until

oil pan and cylinder block. Remove the rear main

oil emerges from the outlet opening.

bearing cap to oil pan seal and cylinder front

(2) Coat a new oil pump gasket with oil-

cover to oil pan seal. Clean the seal grooves.

resistant sealer and position it on the oil pump.

(2) Apply oil-resistant sealer in the cavities

(3) Install the oil pump on the cylinder block.

between the bearing cap and cylinder block (fig.

Torque the attaching bolts to specifications.

6-45. Oil Pump Repair

cap and apply a bead of oil-resistant sealer to the

tapered ends of the seal.

a. Disassembly.

(3) Install new side gaskets on the oil pan

(1) Remove the cover attaching screws and

with oil resistant sealer (fig. 6-42). Position a new

remove the cover (fig. 6-58).

oil pan to cylinder front cover seal on the oil pan.

(4) Clean the inlet tube and screen assembly

and place it in the oil pan, if previously removed.

(5) Position the oil pan under the engine.

Install the inlet tube and screen assembly on the

oil pump with a new gasket. Torque the screws to

specifications. Position the oil pan against the

cylinder block and install the attaching bolts.

Torque the bolts in sequence to specifications. See

a. Removal.

(1) Remove the oil pan as described in

shown in figure 6-57.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |