|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-34

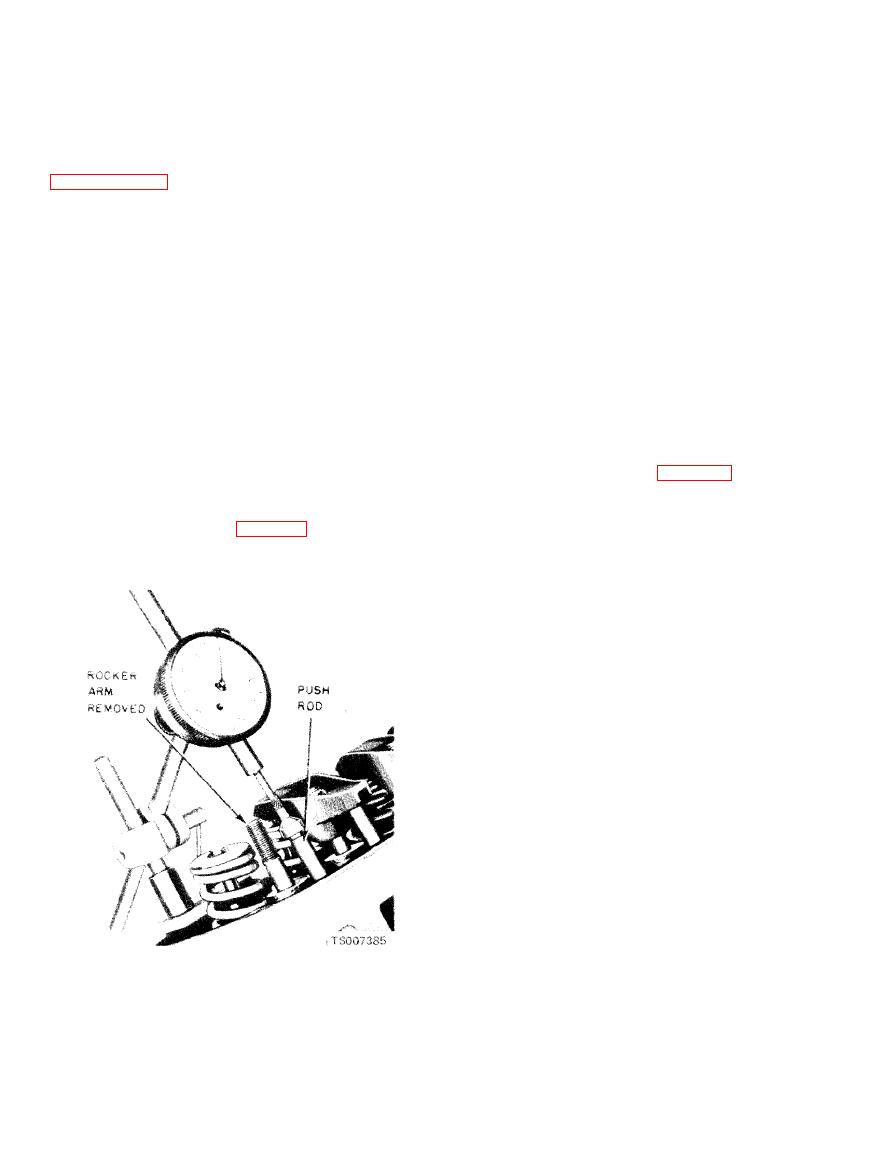

(2) Make sure the pushrod is in the valve

unless the camshaft lobe lift loss has exceeded

lifter socket. Install a dial indicator so that the

0.005 inch.

actuating point of the indicator is in the pushrod

(4) The lift of camshaft lobes can be checked

socket (or the indicator ball socket adapter is on

with the camshaft installed in the engine or on

the end of the pushrod) and in the same plane as

centers. Refer to Camshaft Lobe Lift Check,

the pushrod movement.

(3) Disconnect the brown lead (I terminal)

(5) Check the distributor drive gear for

and the red and blue lead (S terminal) at the

broken or chipped teeth.

starter relay. Install an auxiliary starter switch

( 6 ) Check the fuel pump eccentric for

between the battery and S terminals of the starter

grooving or obvious wear.

relay. Crank the engine with the ignition switch

(7) Minor scoring or nicks maybe dressed out

OFF.

with an oilstone. However, if journals are severly

marred or worn beyond the wear limit, replace the

b. Procedure.

camshaft.

(1) Using auxiliary starter switch, turn the

crankshaft over until the tappet or lifter is on the

base circle of the camshaft lobe. At this point, the

NOTE

pushrod will be in its lowest position.

The procedure following is for checking lobe lift with

(2) Zero the dial indicator. Continue to rotate

camshaft installed. Lobe lift may be checked with

the crankshaft slowly until the pushrod is in the

camshaft between centers by setting up the dial

fully raised position.

indicator so that it bears directly on the camshaft

lobe.

(3) Compare the total lift recorded on the

indicator with specifications (table 6-7).

a. Set-Up.

(4) To check the accuracy of the original

(1) Remove rocker arm cover. Remove rocker

indicator reading,

c o n t i n u e to rotate the

arm stud nut, fulcrum seat and rocker arm. Use

crankshaft until the indicator reads zero. If the

an adapter as illustrated (fig. 6-56) for ball end

lift on any lobe is below specified wear limits, the

pushrods.

camshaft and the valve lifters operating on the

worn lobe(s) must be replaced.

6-40

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |