|

|||

|

|

|||

|

Page Title:

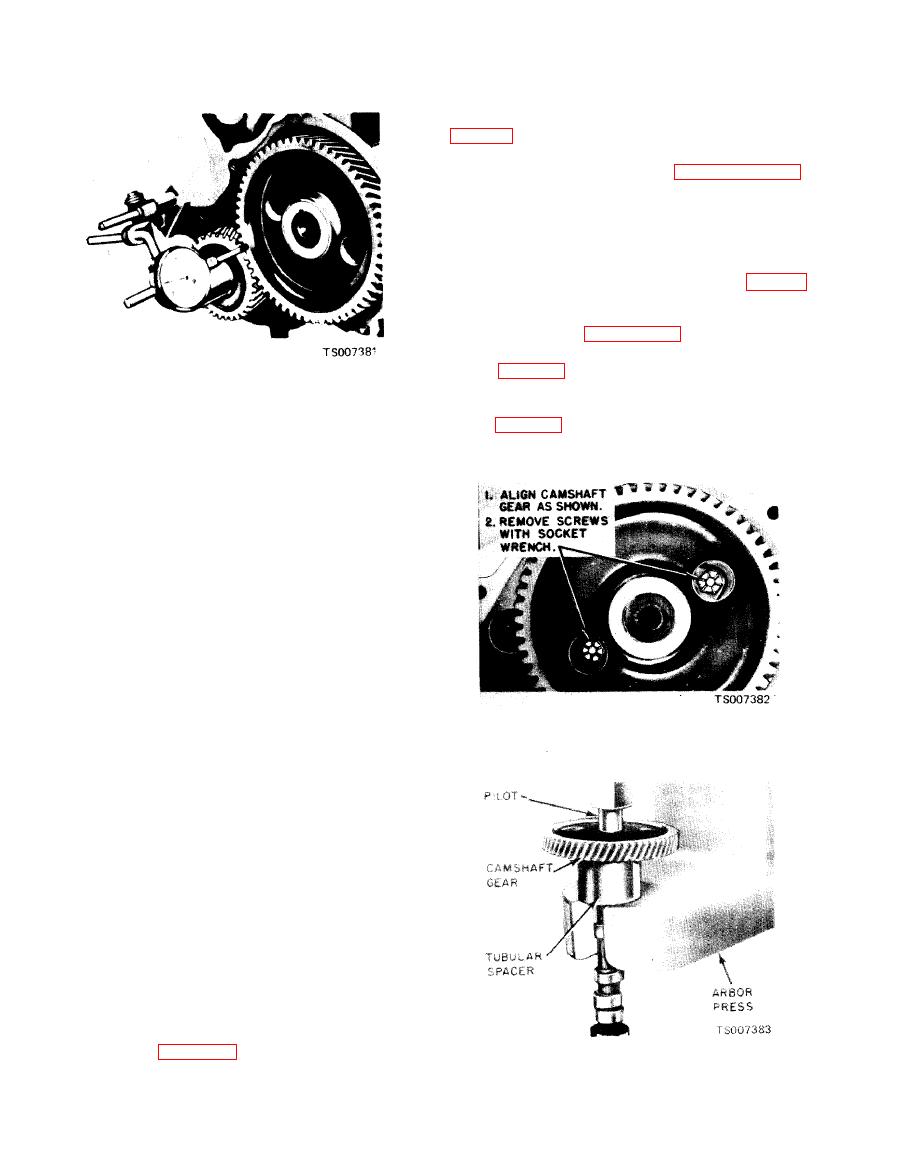

Figure 6-52. Checking Timing Gear Runout. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(6) Remove the capscrew and washer from

the end of the crankshaft. Remove the damper

(7) Remove the oil pan and related parts by ,

following the procedure under paragraph 6-43.

Remove the oil pump screen and inlet tube

assembly.

(8) Remove the cylinder front cover and

discard the gasket.

(9) Check the camshaft end play, the timing

gear backlash and the timing gear runout (para 6-

38).

(10) Turn the crankshaft to align the timing

marks as shown in figure 6-36.

(11) Remove the camshaft thrust plate

screws (fig. 6-53). Remove the camshaft. Avoid

damaging the camshaft lobes during removal.

Press the camshaft out of the gear in an arbor

press (fig. 6-54). Remove the key, thrust plate

(2) Hold the camshaft gear against the

and spacer.

thrust plate, and zero the indicator.

( 3 ) Rotate the crankshaft to turn the

camshaft, while holding the camshaft gear

against the thrust plate.

(4) Check gear runout through one complete

revolution of the camshaft.

(5) If the gear runout exceeds specifications,

remove it and check for burrs or foreign particles

on or between the camshaft and gear joining

flanges. Check the runout. If it still exceeds

specifications, replace both gears.

(6) Follow the above procedure to check

crankshaft gear runout.

a. Removal.

(1) Disconnect the spark plug wires at the

spark plugs and disconnect the secondary high

tension wire at the ignition coil. Remove the

distributor cap and spark plug wires as an

assembly.

(2) Disconnect the fuel outlet lines at the fuel

pump. Remove the fuel pump mounting bolts and

position the fuel pump out of the way.

( 3 ) Disconnect the vacuum line at the

distributor and the primary wire at the coil.

Remove the distributor.

(4) Remove the valve rocker arm cover.

Loosen the rocker arm stud nuts, move the rocker

arms to one side and remove the pushrods in

sequence. Place the pushrods in a rack so they can

be installed in their original locations.

(5) Remove the valve pushrod cover; then

remove the valve lifters in sequence, using the

tool shown in figure 6-6. Place the valve lifters in

a tray or rack to facilitate installation in the same

sequence in which they were removed.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |