|

|||

|

|

|||

|

Page Title:

RESISTANCE TEST |

|

||

| ||||||||||

|

|

TM 9-2320-364-20-1

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads and

gloves. Hot engine components will burn and cause injury to personnel.

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry or tools contact positive electrical

circuits, a direct short may result. Damage to equipment, injury or death to personnel may occur.

Corrosion inhibitor contains alkali. Do not get in eyes; wear goggles/safety glasses when using. Avoid contact

with skin. In case of contact, immediately wash area with soap and water. If eyes are contacted, flush eyes

with large amounts of water for at least 15 minutes and get immediate medical attention.

While applying torque to nut, hold screw with wrench or damage to battery may occur.

DDEC ECM connector terminals are easily damaged. Use care when connecting and disconnecting terminals.

RESISTANCE TEST

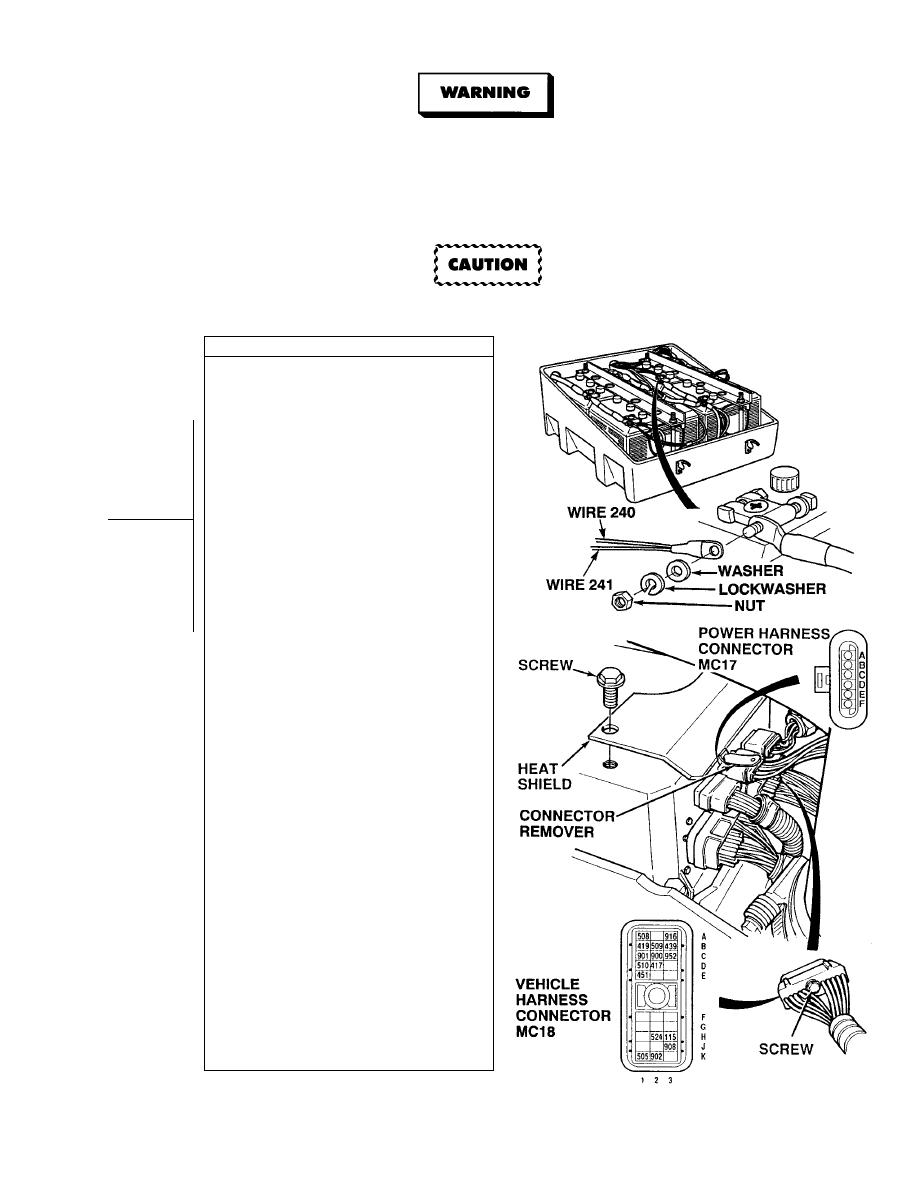

(1) Remove battery box cover.

(2) Remove nut, washer, lockwasher, wires

240 and 241 from battery. Discard

lockwasher.

(3) Remove two screws and heatshield from

DDEC ECM.

(4) Disconnect power harness connector

MC17 from DDEC ECM with connector

remover.

(5) Loosen screw and disconnect vehicle

harness connector MC18 at DDEC ECM.

(6) Are there more than 10,000 ohms

present between terminals D1 and B3 at

vehicle harness connector MC18.

(a) If less than 10,000 ohms are present,

repair wires 240 and/or 241 (see

schematic Fig 2-3) or notify DS

Maintenance and perform Steps (8)

through (15) below.

(b) If more than 10,000 ohms are

present, go to Step (6) below.

(7) Are there less than 10,000 ohms present

on the following wires:

wire 150 between power connector

MC17, terminal C and vehicle

harness connector MC18, terminal D1

wire 150 between power connector

MC17, terminal D and vehicle

harness connector MC18, terminal D1

wire 240 between power connector

MC17, terminal E and vehicle

harness connector MC18, terminal D1

wire 240 between power connector

MC17, terminal F and vehicle

harness connector MC18, terminal D1

(a) If less than 10,000 ohms are present,

repair wires (see schematic Fig 2-3)

or notify DS Maintenance.

(b) If more than 10,000 ohms are

present, perform Steps (8) through

(15) below.

(8) Connect power harness connector C17

to DDEC ECM.

(9) Connect vehicle harness connector

MC18 to DDEC ECM.

(10) Install heatshield with two screws.

(11) Connect wires 240 and 241 to battery

with washer, lockwasher and nut.

(12) Tighten nut to 23 lb-ft (31 N.m).

(13) Apply corrosion preventive compound

on nut.

(14) Install battery box cover.

(15) Close top engine access cover.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |