|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

The crankshaft must be free of oil at the contact

i01738512

points of Tooling (A).

Bearing Clearance - Check

1. Put a piece of Tooling (A) on the crown of the

SMCS Code: 1203-535; 1219-535

bearing that is in the cap.

Measurement Procedure

Note: Do not allow Tooling (A) to extend over the

edge of the bearing.

Table 46

Required Tools

order to install the bearing cap. Do not use an

Part

impact wrench. Be careful not to dislodge the

Tool

Part Description

Qty

Number

bearing when the cap is installed.

1

198-9142

Plastic Gauge

Note: Do not turn the crankshaft when Tooling (A)

1

198-9143

Plastic Gauge

is installed.

A

1

198-9144

Plastic Gauge

3. Carefully remove the cap, but do not remove

1

198-9145

Plastic Gauge

Tooling (A). Measure the width of Tooling (A)

while Tooling (A) is in the bearing cap or on the

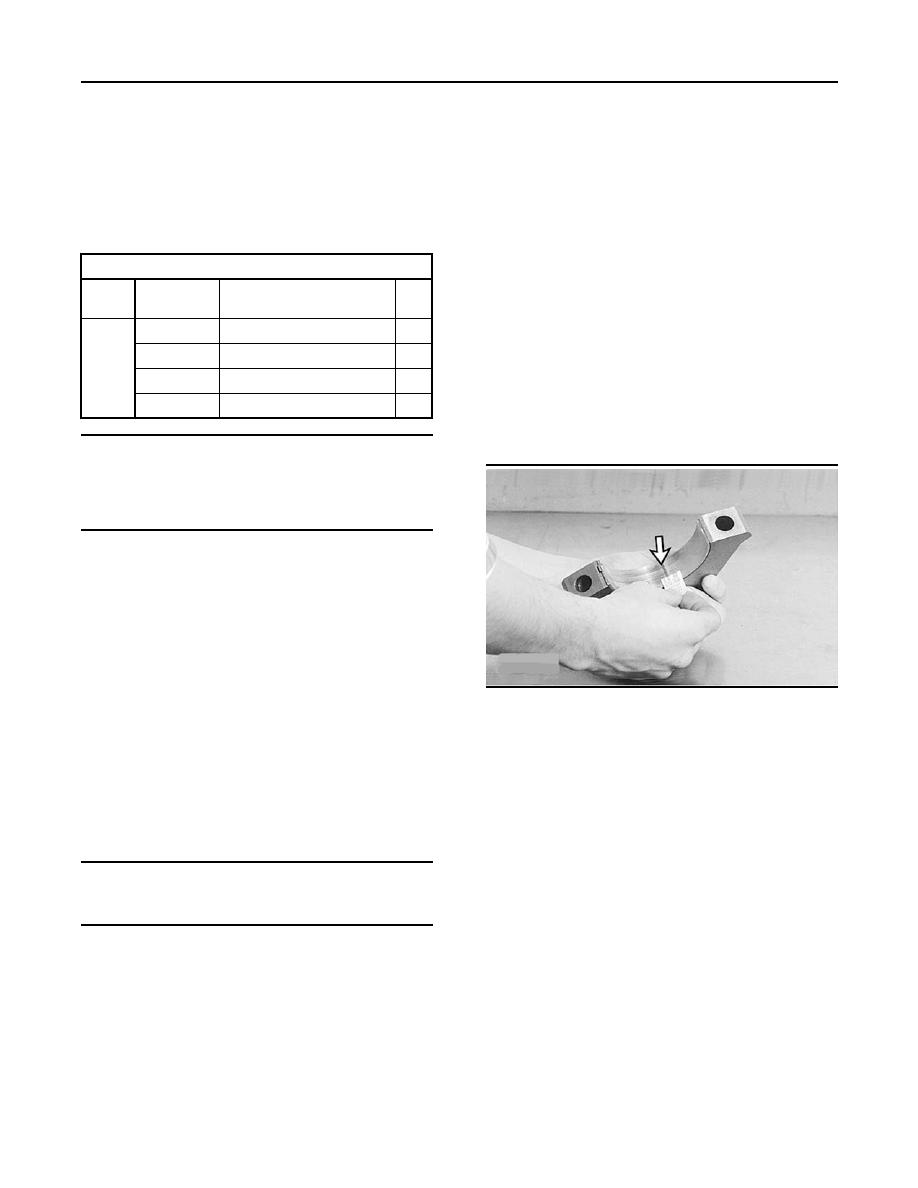

crankshaft journal. Refer to Illustration 239.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: Caterpillar does not recommend the checking

of the actual bearing clearances particularly on

small engines. This is because of the possibility of

obtaining inaccurate results and the possibility of

damaging the bearing or the journal surfaces. Each

Caterpillar engine bearing is quality checked for

specific wall thickness.

Note: The measurements should be within

g00473227

Illustration 239

specifications and the correct bearings should

be used. If the crankshaft journals and the bores

Typical Example

for the block and the rods were measured during

4. Remove all of Tooling (A) before you install the

disassembly, no further checks are necessary.

bearing cap.

However, if the technician still wants to measure the

bearing clearances, Tooling (A) is an acceptable

Note: When Tooling (A) is used, the readings

method. Tooling (A) is less accurate on journals

can sometimes be unclear. For example, all

with small diameters if clearances are less than

parts of Tooling (A) are not the same width.

0.10 mm (0.004 inch).

Measure the major width in order to ensure that

the parts are within the specification range. Refer

NOTICE

to Specifications, "Crankshaft" for the correct

Lead wire, shim stock or a dial bore gauge can dam-

clearances.

age the bearing surfaces.

The technician must be very careful to use

Tooling (A) correctly. The following points must be

remembered:

Ensure that the backs of the bearings and the

bores are clean and dry.

Ensure that the bearing locking tabs are properly

seated in the tab grooves.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |