|

|||

|

|

|||

|

Page Title:

Inspection With The Engine Running |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Testing and Adjusting Section

1. Examine the fuel system for leaks. Ensure that

Covering the opening will stop the air supply to

the fuel line fittings are properly tightened. Check

the engine, so the engine will stop.

the fuel level in the fuel tank. Air can enter the

fuel system on the suction side between the fuel

Inspection With The Engine

transfer pump and the fuel tank.

Running

2. Install a 2P-8278 Fuel Flow Tube (Sight Gauge)

Either too much fuel for combustion or not enough

in the fuel return line. When possible, install the

fuel for combustion can be the cause of a problem

sight gauge in a straight section of the fuel line

in the fuel system. Finding the source of the problem

that is at least 304.8 mm (12 inches) long. Do not

can be difficult, especially when you have smoke

install the sight gauge near the following devices

that rises from the exhaust. Therefore, work is often

that create turbulence:

done on the fuel system when the problem is really

with some other part of the engine.

Elbows

When noticeable smoke rises from the exhaust, this

Relief valves

problem can be caused by a damaged unit injector.

This unusual smoke can also be caused by one or

Check valves

more of the reasons that follow:

Observe the fuel flow during engine cranking.

not enough air for good combustion

Look for air bubbles in the fuel. If there is no fuel

in the sight gauge, prime the fuel system. Refer

an overload at high altitude

to Testing and Adjusting, "Fuel System - Prime"

for more information. If the engine starts, check

oil leakage into combustion chamber

for air in the fuel at varying engine speeds.

When possible, operate the engine under the

altitude

conditions which have been suspect of air in the

fuel.

air inlet and exhaust leaks

Note: Refer to Troubleshooting for more information

on the fuel system.

Checking The Operation Of

Individual Cylinders

Low temperature at an exhaust manifold port is

an indication of no fuel to the cylinder. This can

possibly be an indication of an injector with a

defect. An extra high temperature at an exhaust

manifold port can be an indication of too much fuel

to the cylinder. High temperatures may also be

caused by an injector with a defect.

Refer to Testing And Adjusting, "Exhaust

Temperature - Test" for the procedure for checking

the temperatures in the exhaust manifold port.

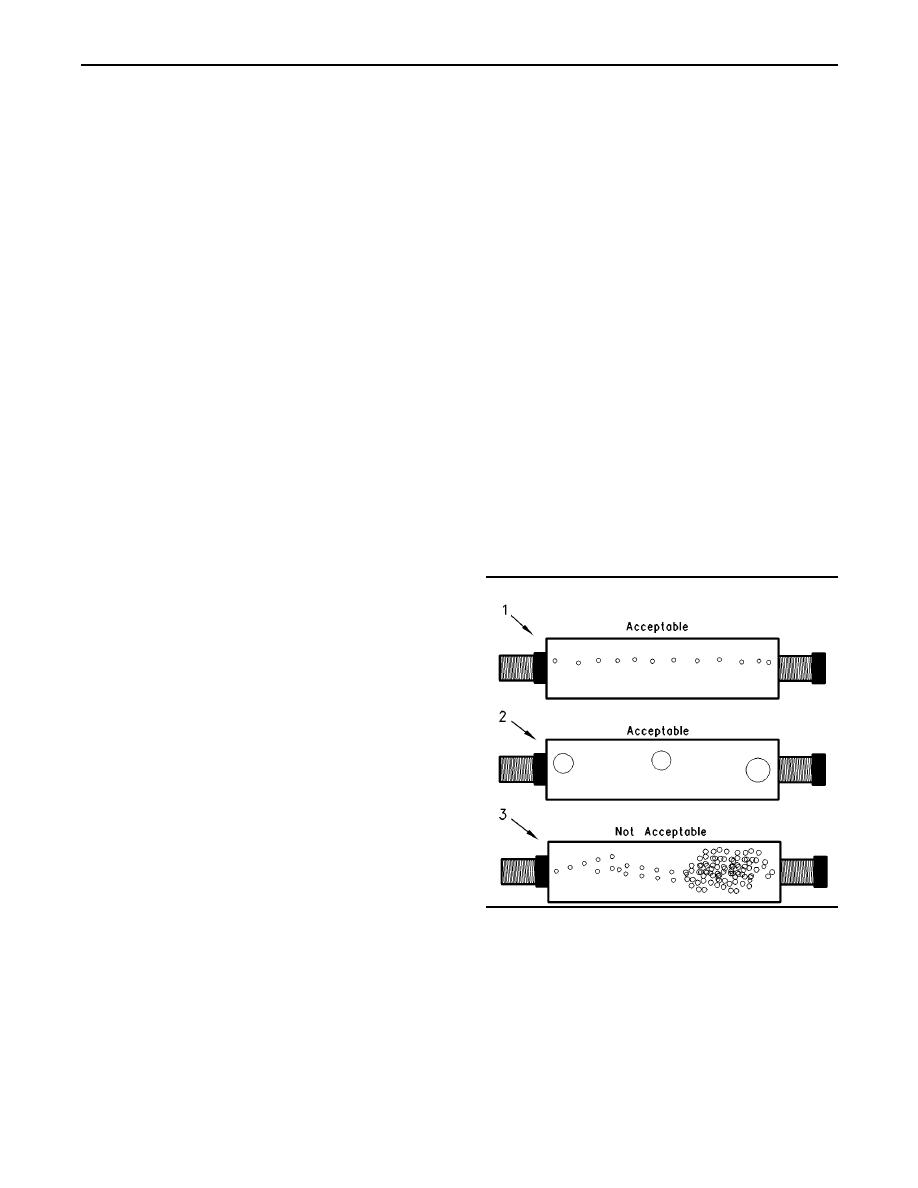

g00578151

Illustration 43

i01459442

2P-8278 Fuel Flow Tube (Sight Gauge)

Air in Fuel - Test

(1) A steady stream of small bubbles with a diameter of

approximately 1.60 mm (0.063 inch) is an acceptable amount

SMCS Code: 1280-081

of air in the fuel.

(2) Bubbles with a diameter of approximately 6.35 mm (0.250 inch)

are also acceptable if there is two seconds to three seconds

This procedure checks for air in the fuel. This

intervals between bubbles.

procedure also assists in finding the source of the

(3) Excessive air bubbles in the fuel are not acceptable.

air.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |