|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Testing and Adjusting Section

3. If excessive air is seen in the sight gauge in the

i01287795

fuel return line, install a second sight gauge at

Engine Speed - Check

the inlet to the fuel transfer pump. If a second

sight gauge is not available, move the sight

SMCS Code: 1000

gauge from the fuel return line and install the

sight gauge at the inlet to the fuel transfer pump.

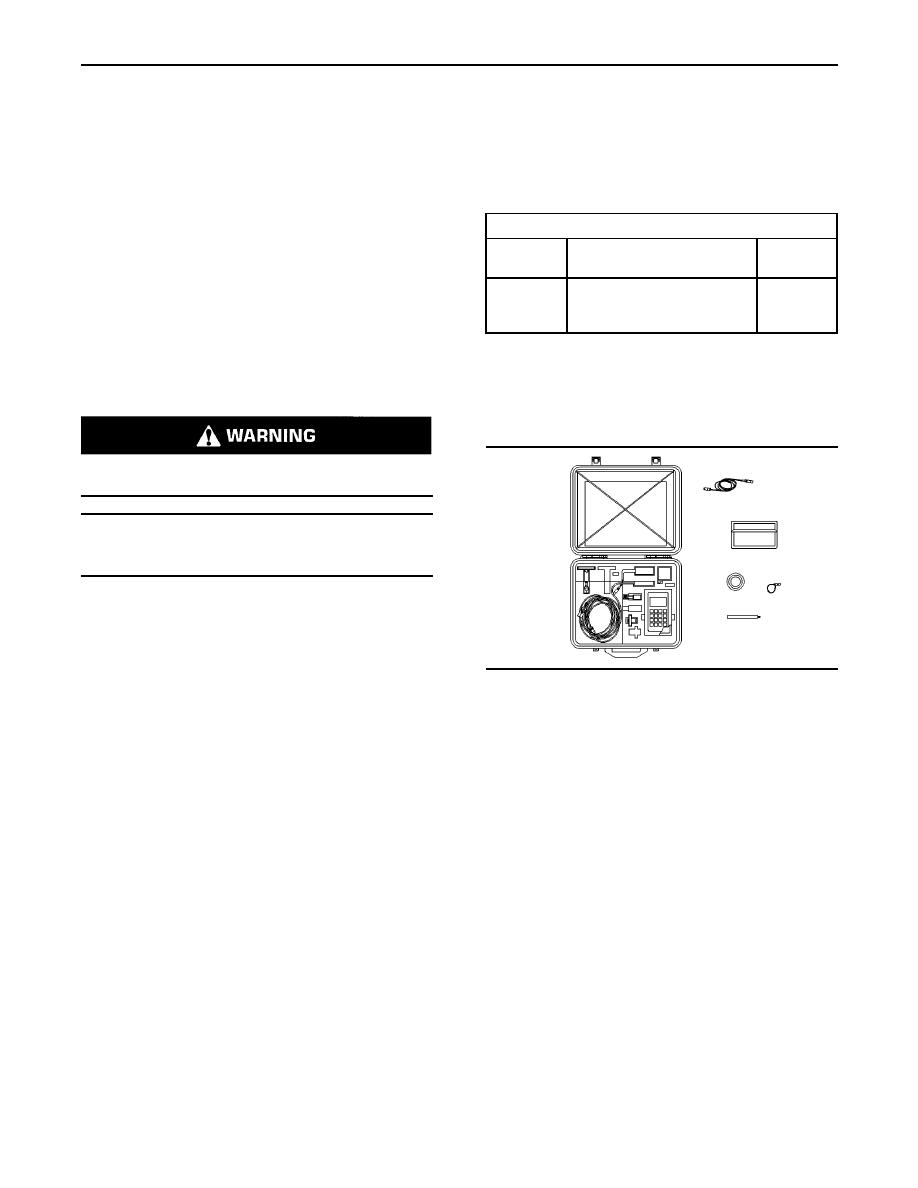

Table 3

Observe the fuel flow during engine cranking.

Look for air bubbles in the fuel. If the engine

Tools Needed

starts, check for air in the fuel at varying engine

Part

Part Name

Quantity

speeds.

Number

1U-6602

1

Photo-Tachometer(1)

If excessive air is not seen at the inlet to the fuel

or

or

transfer pump, the air is entering the system after

9U-7400

Multitach Tool Group

the fuel transfer pump. Proceed to Step 6.

(1)

This unit is a hand-held service tool.

If excessive air is seen at the inlet to the fuel

transfer pump, air is entering through the suction

Note: The Electronic Service Tools can also be used.

side of the fuel system.

You can observe the engine rpm, which is displayed

on the status screen of the electronic service tool.

To avoid personal injury, always wear eye and face

protection when using pressurized air.

NOTICE

To avoid damage, do not use more than 55 kPa (8 psi)

to pressurize the fuel tank.

4. Pressurize the fuel tank to 35 kPa (5 psi). Do not

use more than 55 kPa (8 psi) in order to avoid

damage to the fuel tank. Check for leaks in the

fuel lines between the fuel tank and the fuel

transfer pump. Repair any leaks that are found.

g00286276

Illustration 44

Check the fuel pressure in order to ensure that

the fuel transfer pump is operating properly. For

9U-7400 Multitach Tool Group

information about checking the fuel pressure, see

Testing and Adjusting, "Fuel System Pressure

The 9U-7400 Multitach Tool Group can measure

- Test".

engine rpm from a magnetic pickup. This magnetic

pickup is located in the flywheel housing. The

5. If the source of the air is not found, disconnect

multitach also uses the ability to measure engine

the supply line from the fuel tank and connect an

rpm from visual engine parts that are rotating.

external fuel supply to the inlet of the fuel transfer

pump. If this corrects the problem, repair the fuel

Note: Refer to Special Instruction, NEHS0605 that

tank or the stand pipe in the fuel tank.

is with the 9U-7400 Multitach Tool Group. This

manual gives instructions for the test procedure.

6. If the injector sleeve is worn or damaged,

combustion gases may be leaking into the

The 1U-6602 Photo-Tachometer is a phototach for

fuel system. Also, if the O-rings on the injector

general use. This tachometer can only register the

sleeves are worn, missing, or damaged,

basic input frequency on any rotating part that is

combustion gases may leak into the fuel system.

visible. The basic input frequency is 1 pulse per

revolution per piece of reflective tape.

Note: Refer to Special Instruction, SEHS8854 that is

with this group. This manual provides instructions

for using this tool.

Note: The measurement of engine rpm can be set

with the Electronic Service Tool. Refer to Electronic

Troubleshooting.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |