|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Testing and Adjusting Section

Testing and Adjusting

5. Install a new fuel filter (6).

Section

6. Cut the old filter open with the 4C-5084 Oil Filter

Cutter. Inspect the filter for excess contamination.

Determine the source of the contamination. Make

the necessary repairs.

Fuel System

7. Service the primary fuel filter (if equipped).

i01334705

8. Operate the hand priming pump (if equipped). If

uneven resistance is felt, test for air in the fuel.

Fuel System - Inspect

Refer to Testing and Adjusting, "Air in Fuel - Test"

for more information.

SMCS Code: 1250-040

9. Remove any air that may be in the fuel system.

Initial Inspection Of The Fuel

Refer to Testing and Adjusting, "Fuel System -

Prime".

System

Start Up Procedure

A problem with the components that send fuel to

the engine can cause low fuel pressure. This can

decrease engine performance.

Note: Refer to Operation and Maintenance Manual,

"Engine Starting" in the Operation Section.

After work has been done on the fuel system,

consider the following precautions before you start

the engine. Make sure that you use this starting

procedure to start the engine only after the fuel

system has been worked on:

1. Disconnect the air inlet system from the

turbocharger.

Be careful when placing the steel plate against

the opening on the turbocharger air inlet. To avoid

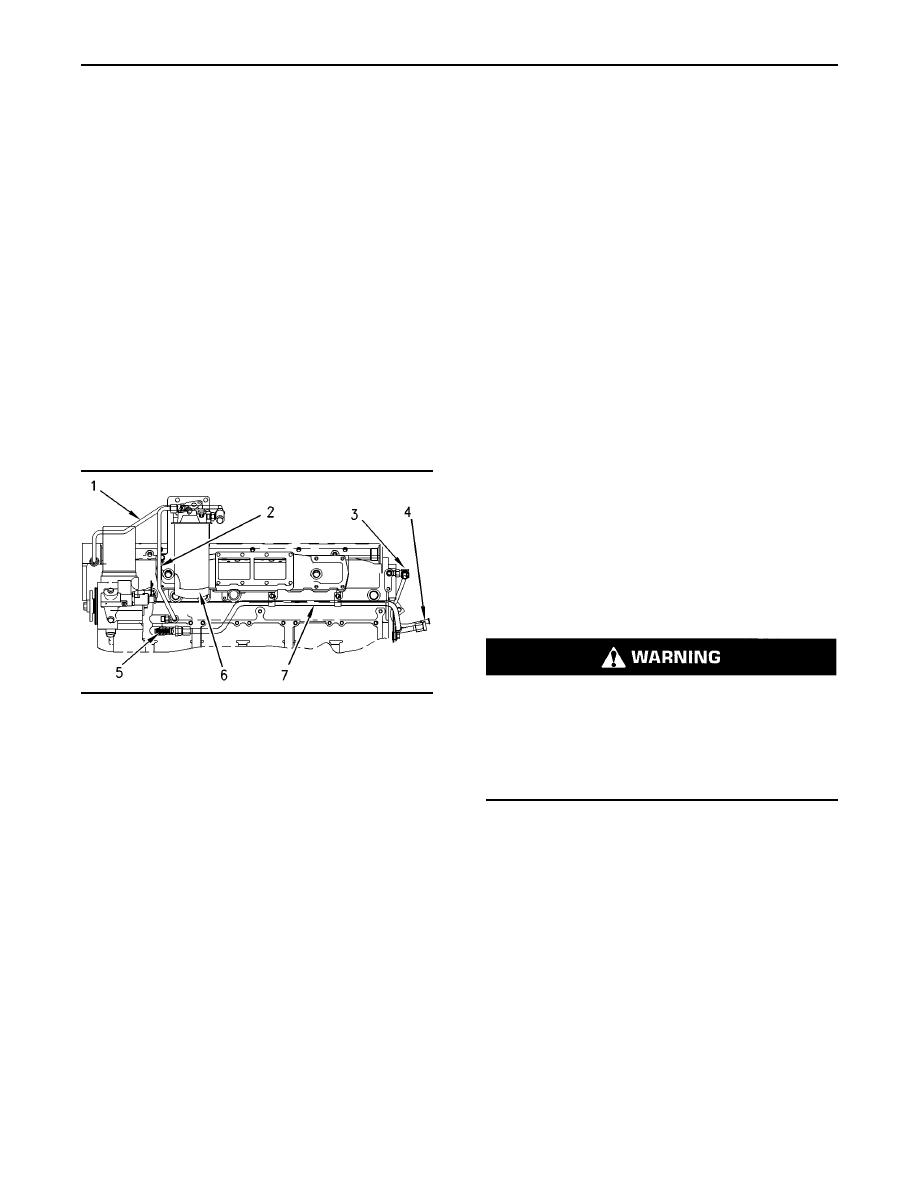

g00296730

Illustration 42

crushed fingers, do not position fingers between

Fuel System

the steel plate and the opening on the turbocharg-

(1) Tube assembly (fuel filter to fuel supply passage)

er air inlet. Due to excessive suction, the plate can

(2) Tube assembly (fuel transfer pump to fuel filter)

be forcefully pulled against the opening on the tur-

(3) Pressure regulator

bocharger air inlet.

(4) Tube assembly (tank return line)

(5) Fuel inlet port (fuel transfer pump)

(6) Fuel filter

2. Another person will need to help as a

(7) Tube assembly

precautionary step. This person should be ready

1. Check the fuel level in the fuel tank. Inspect the

to use the steel plate to cover the turbocharger

cap for the fuel tank. Ensure that the vent in the

air inlet if a problem occurs.

fuel cap is not filled with dirt.

Note: Make sure that the steel plate is large enough

2. Check all fuel lines for fuel leakage. The fuel lines

to cover the entire turbocharger air inlet.

must be free from restrictions and faulty bends.

Verify that the fuel return line is not collapsed.

3. Start the engine.

3. Clean the screen inside the inlet fitting of the fuel

Immediately place the steel plate against the

transfer pump.

opening on the turbocharger air inlet, if the

engine operates in one of the following ways:

4. Operate the hand priming pump (if equipped).

If excessive resistance is felt, inspect the fuel

The engine runs too fast.

pressure regulating valve (3). Make sure that the

pressure regulator (3) is installed correctly, and

The engine runs out of control.

make sure that the pressure regulator functions

correctly.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |