|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Systems Operation Section

Aftercooler core (2) is a separate cooler core.

i01538883

Aftercooler core (2) is installed in front of the core

Air Inlet and Exhaust System

(standard) of the engine radiator on the machine.

Air that is ambient temperature is moved across

SMCS Code: 1050

the aftercooler core by the engine fan. This cools

the turbocharged inlet air.

From aftercooler core (2), the air is forced into the

cylinder head in order to fill the inlet ports. Air flow

from the inlet port into the cylinder is controlled by

the inlet valves.

g00787037

Illustration 23

Airflow Schematic

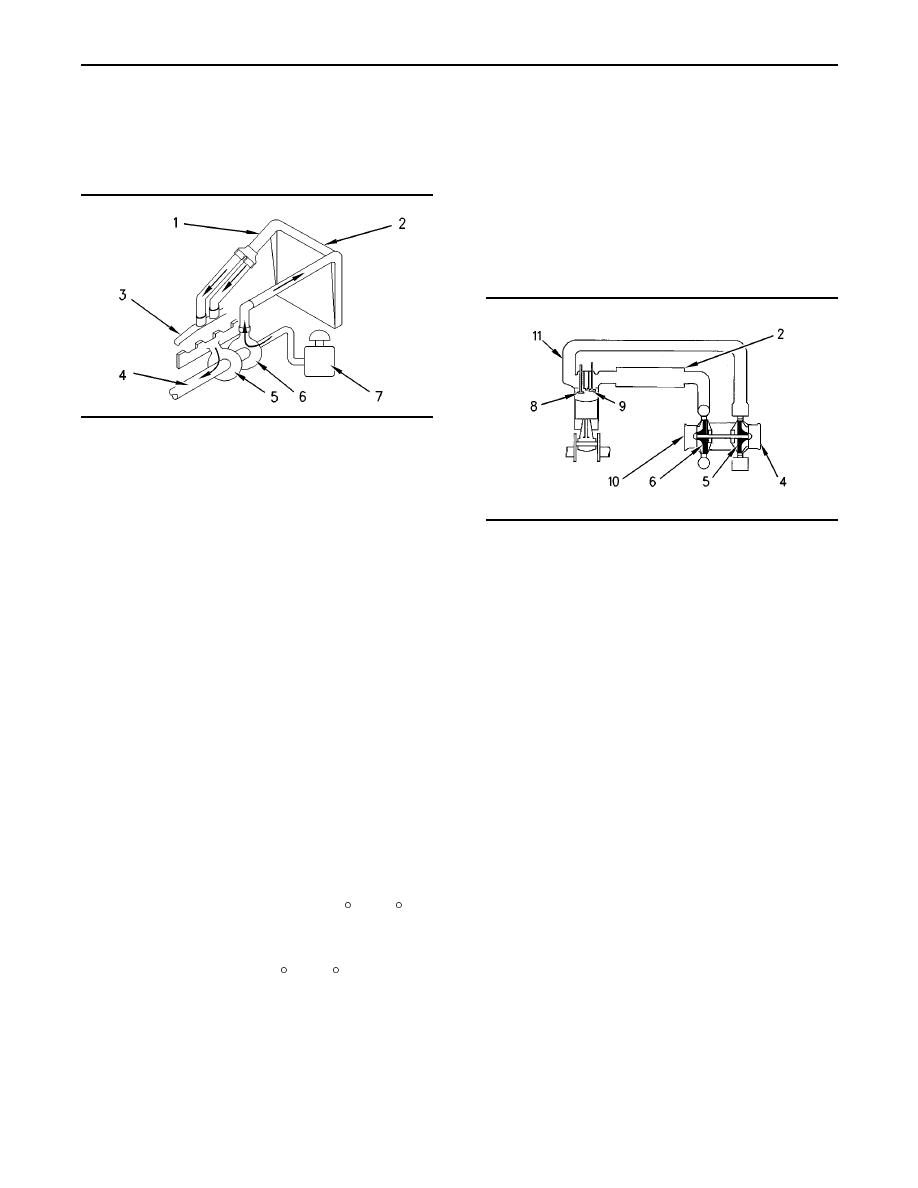

(1) Air line. (2) Aftercooler core. (3) Air inlet elbow. (4) Exhaust

outlet from turbocharger. (5) Turbine side of turbocharger. (6)

Compressor side of turbocharger. (7) Air cleaner.

The components of the air inlet and exhaust system

g00805952

Illustration 24

control the quality of the air that is available for

Air Inlet And Exhaust System

combustion. These components also control the

(2) Aftercooler core. (4) Exhaust outlet. (5) Turbine side of

amount of the air that is available for combustion.

turbocharger. (6) Compressor side of turbocharger. (8) Exhaust

The components of the air inlet and exhaust system

valve. (9) Inlet valve. (10) Air inlet. (11) Exhaust manifold.

are listed below:

There are two inlet valves and one exhaust valve

Air cleaner

for each cylinder. Inlet valves open when the

piston moves down on the inlet stroke. When the

Turbocharger

inlet valves open, cooled compressed air from

the inlet port is pulled into the cylinder. The inlet

Aftercooler

valves close and the piston begins to move up on

the compression stroke. The air in the cylinder is

Cylinder head

compressed. When the piston is near the top of the

compression stroke, fuel is injected into the cylinder.

Valves and valve system components

The fuel mixes with the air and combustion starts.

During the power stroke, the combustion force

Piston and cylinder

pushes the piston downward. After the power stroke

is complete, the piston moves upward. This upward

Exhaust manifold

movement is the exhaust stroke. During the exhaust

stroke, the exhaust valve opens, and the exhaust

Inlet air is pulled through the air cleaner. The inlet air

gases are pushed through the exhaust port into the

is then compressed and heated by the compressor

exhaust manifold. After the piston completes the

wheel of turbocharger (6) to about 150 C (300 F).

exhaust stroke, the exhaust valve closes and the

The inlet air is then pushed through air-to-air

cycle starts again. The complete cycle consists of

aftercooler core (2) and the inlet air is moved to air

four stages:

inlet elbow (3). The temperature of the inlet air at

air inlet elbow (3) is about 43 C (110 F). Cooling

Inlet stroke

of the inlet air increases the combustion efficiency.

Increased combustion efficiency helps to lower fuel

Compression stroke

consumption. Also, increased combustion efficiency

helps to increase horsepower output.

Power stroke

Exhaust stroke

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |