|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

45

TM 9-2320-312-24-2

Systems Operation Section

When the load on the engine increases, more fuel

Exhaust gases from exhaust manifold (11) enter the

is injected into the cylinders. The combustion of

turbine side of turbocharger (5) in order to turn the

this additional fuel produces more exhaust gases.

turbine wheel. The turbine wheel is connected to a

The additional exhaust gases cause the turbine

shaft which drives the compressor wheel. Exhaust

and the compressor wheels of the turbocharger to

gases from the turbocharger pass through the

turn faster. As the compressor wheel turns faster,

exhaust outlet pipe, the muffler and the exhaust

more air is forced into the cylinders. The increased

stack.

flow of air gives the engine more power by allowing

the engine to burn the additional fuel with greater

Turbocharger

efficiency.

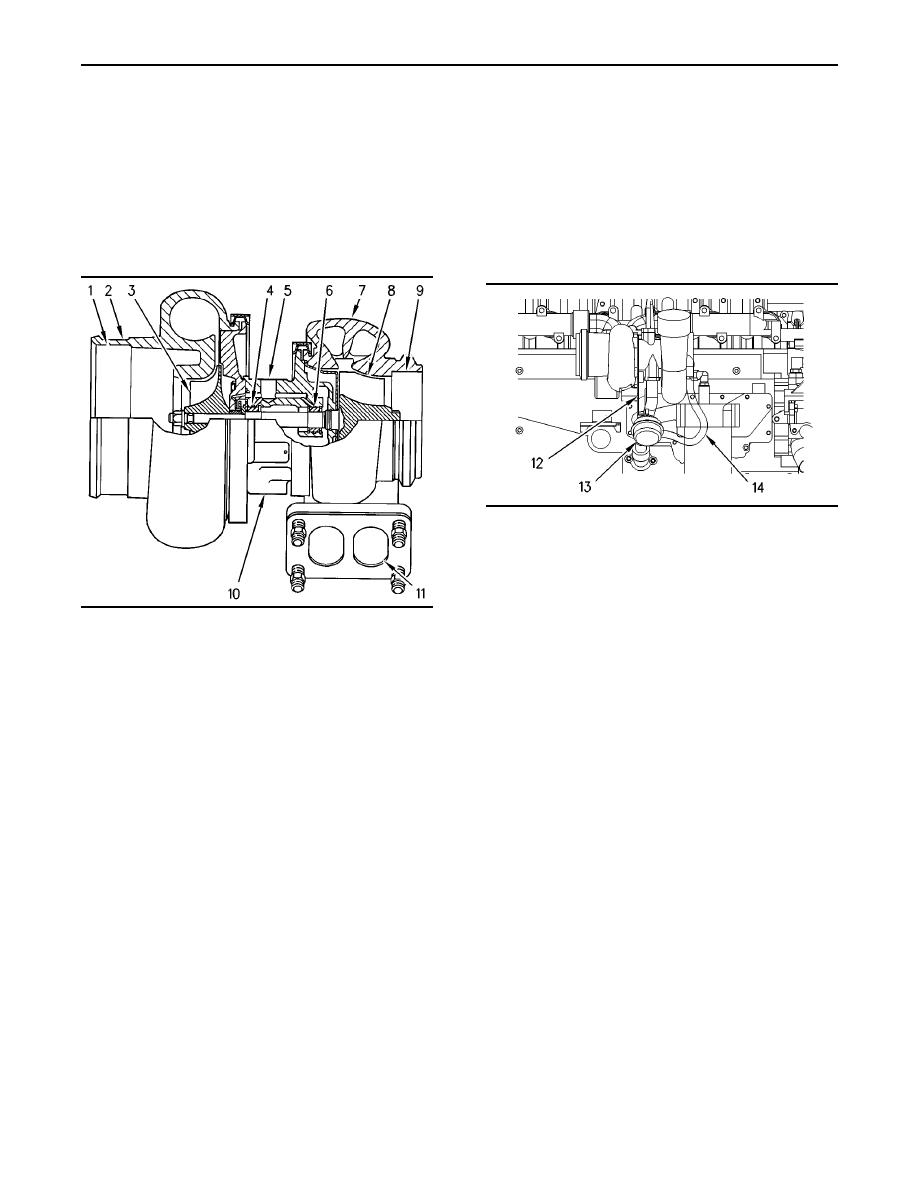

g00294194

Illustration 26

Turbocharger With Wastegate

(12) Actuating lever. (13) Canister. (14) Line (boost pressure).

When the engine is operating under conditions

of low boost, a spring pushes on a diaphragm in

g00294193

Illustration 25

canister (13). This action moves actuating lever (12)

in order to close the valve of the wastegate. Closing

Turbocharger

the valve of the wastegate allows the turbocharger

(1) Air inlet. (2) Compressor housing. (3) Compressor wheel. (4)

to operate at maximum performance.

Bearing. (5) Oil Inlet port. (6) Bearing. (7) Turbine housing. (8)

Turbine wheel. (9) Exhaust outlet. (10) Oil outlet port. (11) Exhaust

inlet.

As the boost pressure through line (14) increases

against the diaphragm in canister (13), the valve

The turbocharger is installed on the center section

of the wastegate is opened. When the valve of the

of the exhaust manifold. All the exhaust gases

wastegate is opened, the rpm of the turbocharger

from the engine go through the turbocharger. The

is limited by bypassing a portion of the exhaust

compressor side of the turbocharger is connected

gases. The exhaust gases are routed through the

to the aftercooler by a pipe.

wastegate which bypasses the turbine wheel of the

turbocharger.

The exhaust gases go into turbine housing (7)

through exhaust inlet (11). The exhaust gases then

Note: The turbocharger with a wastegate is preset

push the blades of turbine wheel (8). The turbine

at the factory and no adjustment can be made.

wheel is connected by a shaft to compressor wheel

(3).

Bearings (4) and (6) for the turbocharger use

engine oil under pressure for lubrication. The oil

Clean air from the air cleaners is pulled through

comes in through oil inlet port (5). The oil then goes

compressor housing air inlet (1) by the rotation of

through passages in the center section in order to

compressor wheel (3). The action of the compressor

lubricate the bearings. Oil from the turbocharger

wheel blades causes a compression of the inlet air.

goes out through oil outlet port (10) in the bottom

This compression gives the engine more power by

of the center section. The oil then goes back to the

allowing the engine to burn more air and more fuel

engine lubrication system.

during combustion.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |