|

|||

|

|

|||

|

Page Title:

Fuel Heater And Water Separator (If Equipped) |

|

||

| ||||||||||

|

|

43

TM 9-2320-312-24-2

Systems Operation Section

Fuel Heater And Water Separator

The end of the injection cycle begins when the ECM

stops the current to the unit injector solenoid. The

(If Equipped)

magnetic field of the solenoid breaks down and the

magnetic field is unable to overcome the spring

force of the poppet. The poppet returns to the

lower poppet seat which closes the poppet valve.

When the poppet valve closes, high pressure oil is

stopped from entering the unit injector. As the lower

poppet seat closes, the upper poppet seat opens

to the drain. When the upper poppet seat opens to

the drain, the actuation pressure of the oil drops off.

Fuel injection pressure under the plunger exerts

an upward force on the plunger and the intensifier

piston. As the pressure of the actuation oil above

the intensifier piston drops off, the downward force

on the intensifier piston drops off. The upward force

of the fuel injection pressure under the plunger

suddenly becomes greater than the downward

force on the intensifier piston. The downward motion

of the intensifier piston and the plunger stops.

The exhaust oil on top of the intensifier piston can

flow to the drain through the open upper poppet

g00291751

seat. Then, the oil flows through a vent hole to the

Illustration 22

rocker arm compartment under the valve cover.

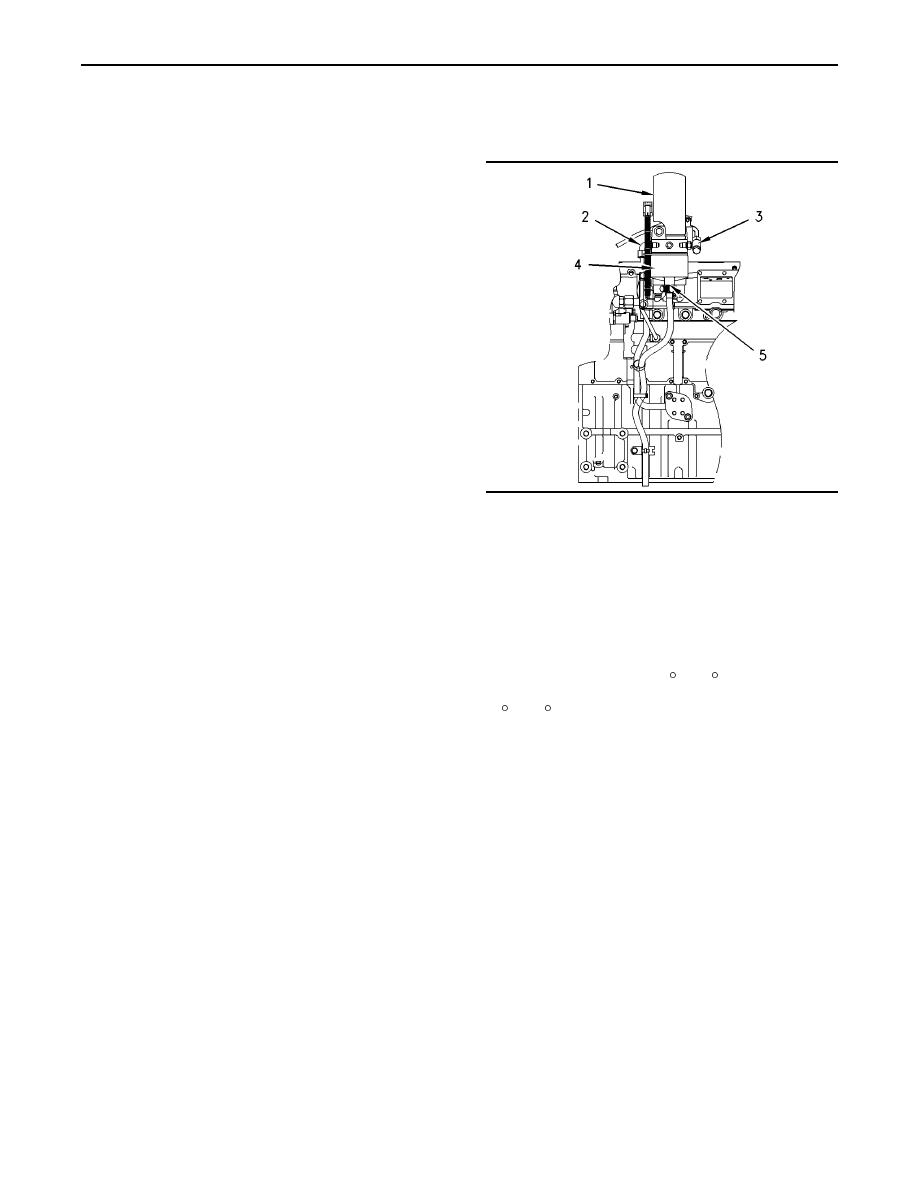

(1)

Fuel filter

(2)

Fuel inlet

When the downward travel of the plunger stops,

(3)

Fuel outlet

(4)

Fuel heater and water separator

fuel flow also stops. While the check is still open,

(5)

Drain valve

the remaining fuel pressure pushes a small amount

of fuel out of the orifice holes. This causes a large

Some engines may have a combination of a fuel

pressure drop which lowers injection pressure

heater and a water separator. The fuel heater is

below Valve Closing Pressure (VCP). Spring tension

controlled by a thermostat that is located in the

on the check now reseats the check into the tip and

base of the unit. The thermostat is preset. When the

injection stops.

fuel temperature is below 4 C (40 F), the thermostat

will turn on the heater. When the fuel temperature is

When the check closes, injection stops. When

15 C (60 F), the thermostat will turn off the heater.

injection stops, the fill cycle starts. The area above

the intensifier piston cavity is open to atmospheric

Water that has been separated from the fuel can be

pressure through the upper poppet seat. Pressure

drained from the unit by lifting up on drain valve (5).

drops very rapidly in the cavity above the intensifier

piston to near zero. The return spring of the plunger

pushes up on the plunger and the intensifier piston.

As the plunger and the intensifier piston move

upward, oil is forced around the upper poppet seat.

After the oil is forced around the upper poppet seat,

the oil is forced out of a vent hole.

As the plunger rises, pressure in the plunger cavity

also drops to near zero. The fuel supply pressure is

450 kPa (65 psi). Fuel supply pressure unseats the

plunger fill check in order to fill the plunger cavity

with fuel. When the intensifier piston is pushed to

the top of the bore, the fill cycle ends. When the

fill cycle ends, the plunger cavity is full and the

inlet fill check ball is reseated. Pressure above the

intensifier piston and the poppet chamber is zero.

The fuel injection cycle is complete and the unit

injector is ready to begin again. The unit injector is

now back in the pre-injection cycle.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |