|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Specifications Section

Guideline For Reusable Parts And Salvage

(7) Diameter of cylinder bore .. 110.025 0.025 mm

Operations, SEBF8192, "Specifications and Salvage

(4.3317 0.0010 inch)

for Cylinder Blocks on 3114, 3116, 3126 and 3126B

Engines"

(8) Distance from the centerline of the crankshaft

bore to the top surface of the cylinder

Guideline For Reusable Parts And Salvage

block .. 322.00 0.17 mm (12.677 0.007 inch)

Operations, SEBF8261, "Installing a 7C-6208

Cylinder Sleeve in 3114 and 3116 Engines and a

(9) Front camshaft bearing joint location

107-7604 Cylinder Sleeve in 3126 Engines"

(10) Bore diameter in the cylinder block for the front

camshaft bearing ............... 70.000 0.025 mm

i01839706

(2.7559 .0010 inch)

Crankshaft

(11) Front camshaft bearing oil hole

SMCS Code: 1202

Note: The front camshaft bearing is installed with

the bearing oil hole (11) in alignment with the oil

hole in the cylinder block and the bearing joint (9)

in the position that is shown.

(12) Tighten the bolt to the following

torque. ...................... 70 10 Nm (50 7 lb ft)

(13) Bearing cap

Width of the main bearing

cap ................................... 159.995 0.020 mm

(6.2990 .0008 inch)

Width of the cylinder block for the main

bearing ............................. 160.000 0.018 mm

(6.2992 .0007 inch)

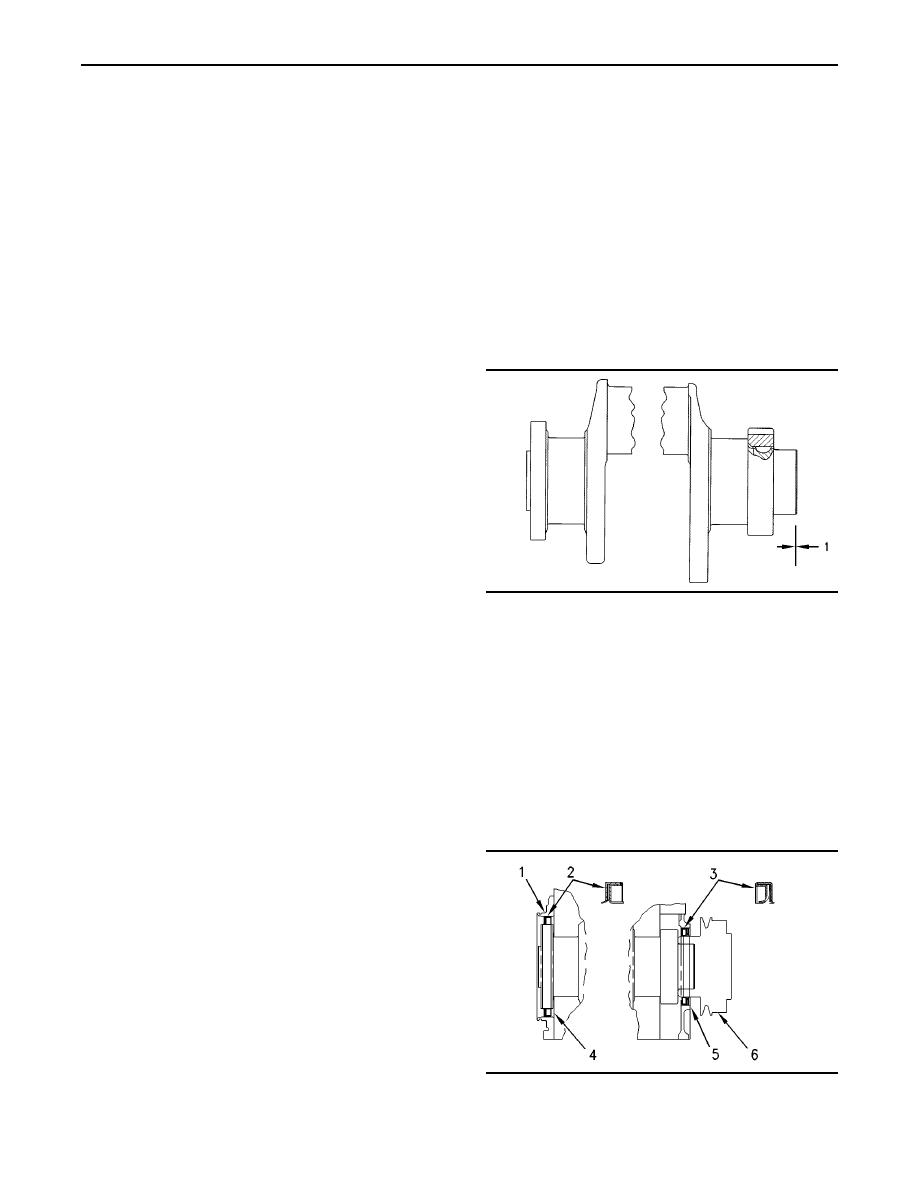

g00939552

Illustration 35

(14) Distance from the centerline of the crankshaft

(1) Crankshaft end play ................. 0.07 to 0.32 mm

bore to the pan rail ..... 110.00 mm (4.331 inch)

(0.003 to 0.013 inch)

(15) Location of the sequence number for the

bearing cap

i01733982

Crankshaft Seals

(16) Main bearing cap bolts

SMCS Code: 1160; 1161

Install the bearing caps with the sequence number

to the right. The order is 1 through 7 (front to rear).

Note: For the complete procedure on removing and

installing the crankshaft seals, refer to Disassembly

1. Apply 4C-5593 Anti-Seize Compound to the bolt

and Assembly.

threads (16) and face of the washers.

2. Tighten bolts (16) on each bearing cap.

Tighten to the following torque. ......... 54 7 Nm

(40 5 lb ft)

3. Tighten bolts (16) on each bearing cap again.

Tighten the bolts by another one quarter of a

turn. ............................................ 90 5 degrees

(17) Bore in the cylinder block for the seven main

bearings ............................. 95.000 0.013 mm

(3.7402 0.0005 inch)

g00291469

Illustration 36

Note: Additional information on reconditioning

procedures can be ordered. Refer to the following

documents:

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |