|

|||

|

|

|||

|

Page Title:

Table 1. Instrument Wiring Troubleshooting Procedures. |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-1

Table 1. Instrument Wiring Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4.

Fuel Level Gage Does Not Operate - 4. Disconnect lead 47 from fuel If +8 to +12 VDC is present,

Continued.

level sensor. Check for +8 to replace fuel level gage sensor (WP

+12 VDC at lead 47.

0090 00). If no voltage is present,

repair lead 47.

5.

Voltmeter Does Not Operate, Warning Light 1. Disconnect lead 19A from If +12 VDC is present, go to step

Operating Normally.

voltmeter. Check for +12 VDC 2. If no voltage is present, repair

at lead 19A.

lead 19A.

2. Disconnect ground lead from

If continuity is indicated, replace

voltmeter. Check for continuity

voltmeter (WP 0062 00). If no

between ground lead and

continuity is indicated, repair

ground.

ground lead.

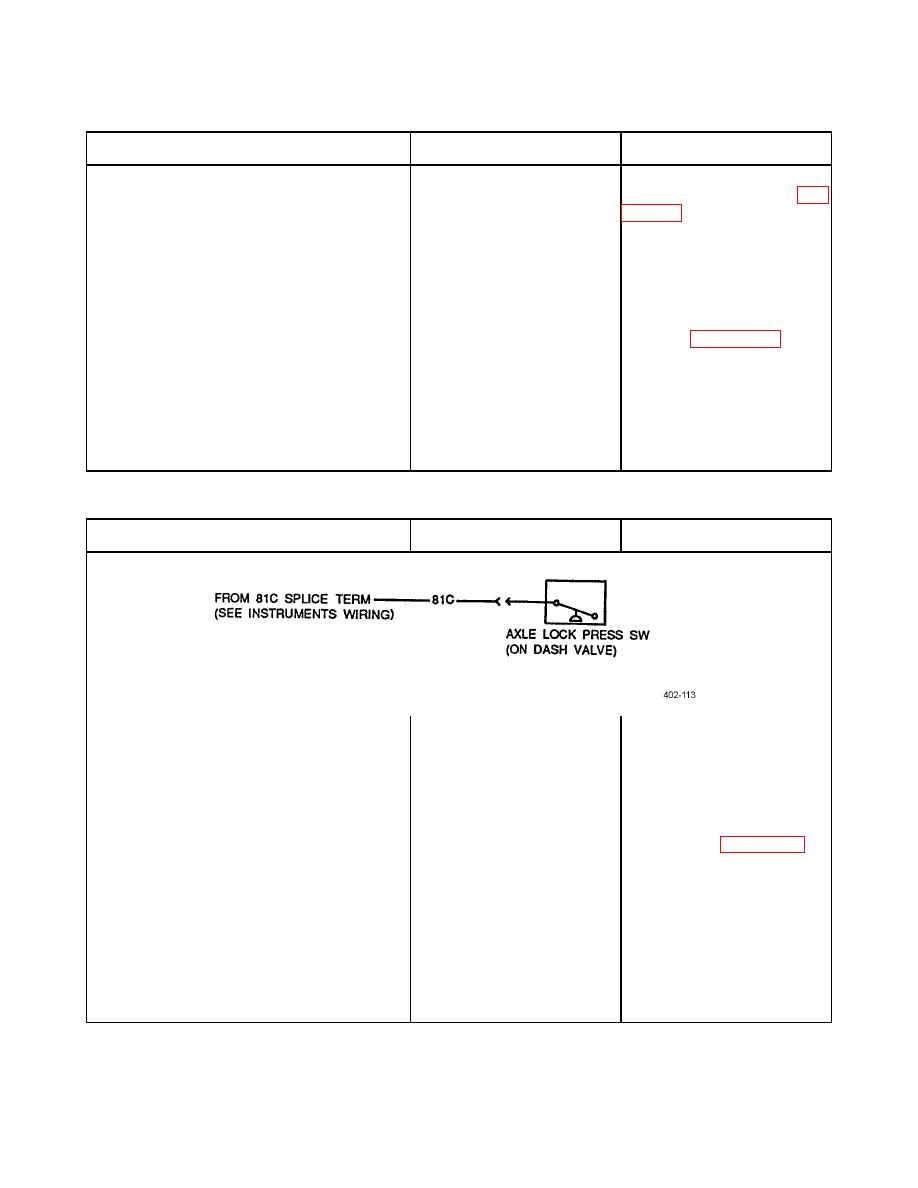

Table 1. Axle Lock Circuit Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Axle Lock Does Not Engage.

1. Disconnect lead 81C from axle If +12 VDC is present, go to step

lock pressure switch. Check for 2. If no voltage is present, repair

+12 VDC at lead 81C.

lead 81C.

2. Disconnect leads 87 and 81C

If continuity is indicated, go to

from axle lock pressure switch.

step 3. If no continuity is

Check for continuity between

indicated, replace axle lock

contacts of switch.

pressure switch (WP 0065 00).

Disconnect lead 87 from axle lock If no continuity is indicated, repair

pressure switch. Check for lead 87.

continuity between lead 87 and

ground.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |