|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-241O-237-34

3-10. CRANKSHAFT ASSEMBLY - REPAIR/REPLACE (Cont'd)

f. Installation

Compressed air used for cleaning

purposes will not exceed 30 psi.

Use only with effective chip

guarding and personal protective

equipment.

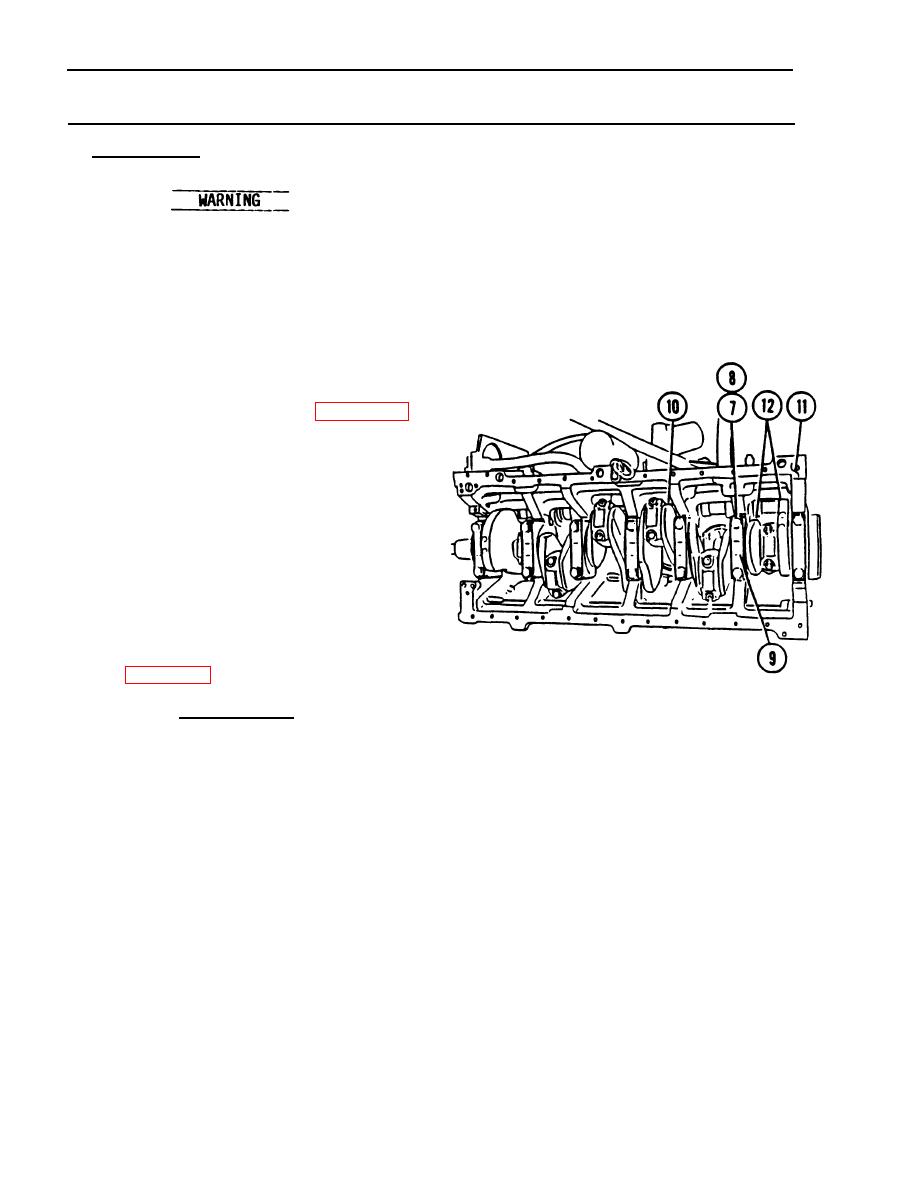

(1) Clean main bearing surfaces in

the cylinder block (11) and the

bearing caps (9) with an approved

cleaning solvent (See page 2-29).

Dry surfaces thoroughly with low

pressure air (30 psi or less).

(2) If anew or altered crankshaft

(10) is installed, new main

bearings must be installed. If

crankshaft was ground to a

smaller size, the correct new

smaller size bearings must be

used. If a crankshaft journal was

polished, new bearings must be

installed for that journal. If

all journals were polished,

install all new bearings. See

CAUTION

It is recommended that nylon

straps, or equivalent, be used

to secure the crankshaft on the

floor jack to prevent damage to

the machined surfaces of the

crankshaft. Be sure that nothing

metallic comes in contact with

the machined surfaces.

(3) Raise the floor jack to install

the crankshaft (10) into correct

location in cylinder block (11).

Check that timing marks (A, B,

and C) are aligned as shown.

Position the crankshaft main

bearing journals firmly against

the upper main bearing halves.

3-48

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |