|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-241O-237-34

3-11.

CRANKSHAFT BEARINGS - REPLACE

This task covers:

a. Removal

b. Cleaning

c. Inspection

d. Installation

e. Place In Service

INITIAL SETUP

Applicable Configurations

Materials

All-

Plastigage

Lubricating Oil OE/HDO-30 (Refer

Common Tools

to LO5-241O-237-12)

Shop Equipment, General Purpose

Cleaning Solvent (App. B, Item 18)

Repair, Semi-Trailer Mounted

Lint-free Rags

NSN 4940-00-287-4894

Shop Equipment, Machine Shop:

Equipment Condition

Field Maintenance, Basic

Engine oilpan plate removed. See

NSN 3470-00-754-0708

Bearing Removal/Installation

Engine oil pump removed. See

Tool

NSN 5120-01-124-1906

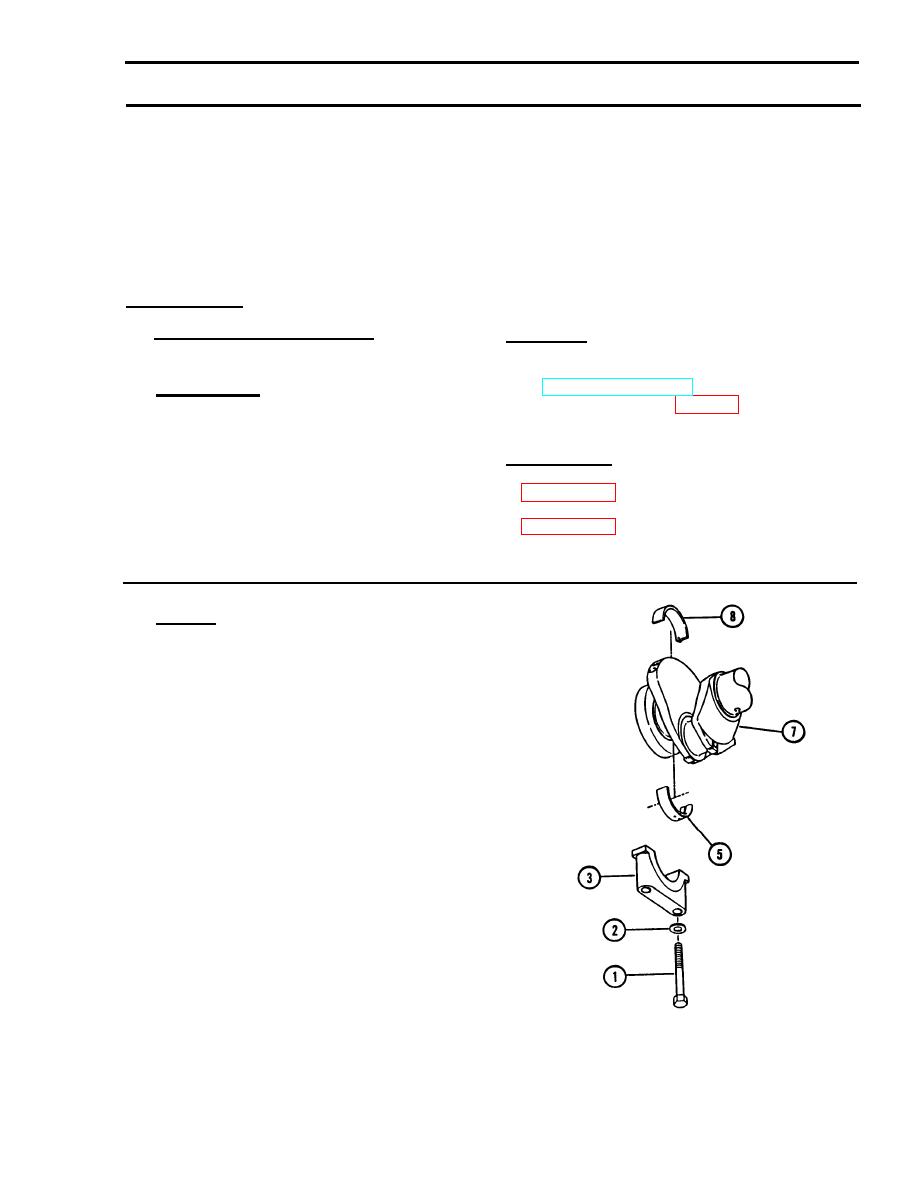

a. Removal

NOTE

Identify main bearings with

the same number that is on the

bearing cap. When used

bearings are reinstalled, each

bearing must be installed in

its original location because

the bearing surfaces have worn

to the crankshaft journals.

(1) Use a wrench to remove capscrews

(1) and washers (2). Remove

bearing caps (3) from cylinder

block (4) for main bearings 1,

3, 5, and 7 ONLY. DO NOT

REMOVE BEARING CAPS FROM

POSITIONS 2, 4, AND 6 MAIN

BEARINGS AT THIS TIME. Remove

lower half of main bearings (5)

from bearing caps (3).

3-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |