|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Inspect the roller sleeve bearings for

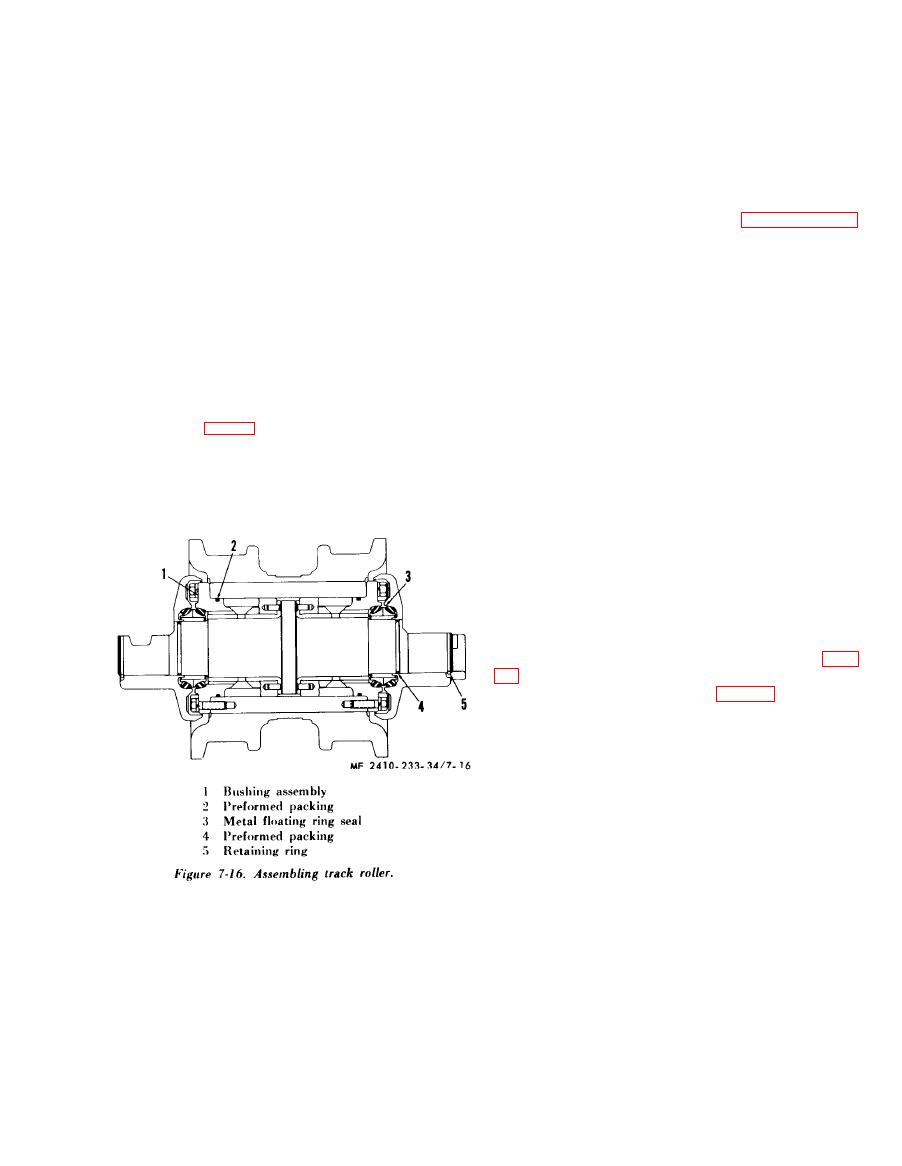

(1) Install the preformed packing (2) on the

bushing (1) and remove any burrs from the roller to

pitting, roughness, and wear. The specified shaft to

bearing clearance i s 0.008-0.012 inch. The

prevent damage to the preformed packing.

maximum allowable shaft to bearing clearance is

NOTE

0.050 inch. The specified shaft end clearance is

White lead should be used on the outside diameter of

the bushing assembly when pressing it into place.

0.011-0.029 inch. The maximum allowable shaft

end clearance is 0.050 inch. Replace pitted, rough,

(2) Install the shaft before pressing in the

or excessively worn bearings.

second bushing.

(3) Inspect the roller shaft for pitting,

(3) Install the metal floating ring seals (3) in

roughness, wear, and distortion. The maximum

the roller and collars as outlined in paragraph 6-22.

allowable bend in roller shaft is 0.005 inch.

(4) Install the preformed packing (4) on the

Replace a damaged, excessively worn, or bent roller

track roller shaft and lubricate it to facilitate in-

shaft.

stallation of the end collar.

(4) Inspect the metal floating ring seals for

(5) Remove any burrs, smooth the chamfer in

damage and proper wear pattern. Replace seals

the bore of the end collar and install the end collar

which are pitted, grooved, scratched across the seal

and the retaining ring (5).

surface, or which show an uneven wear pattern.

(6) Lubricate the roller.

Seals must be replaced in sets.

f. Installation.

e. Assembly.

(1) Install the track roller with notched end

collar toward the center of the tractor.

NOTE

Care should be taken when pressing tbe bushing

(2) Place the roller assemblies on the track in

assembly (1, fig. 7-16) into place to see that the bolt

the proper relative locations and follow the reverse

holes in the bushing flange are held in alignment with

order of removal in completing the installation.

the holes in the roller hub. This can be done by

(3) Place the wedge-shaped lock strip in the

screwing three studs 120 apart into the roller hub to

notch in the end of the shaft and in the notch of tbe

act as guides.

end collar and securely tighten the bolts which hold

the end collars to the track roller frame. Some

clearance will remain between the track roller

frame and the end collars to insure that the ends of

the track roller shaft will be held securely against

the track roller frame.

7-4. Front Idler

a. Removal.

(1) Separate the track and lay it out flat (para

(2) Remove the guard (1, fig. 7-17) bolts (2),

and guide plate (3).

NOTE

Keep the shims from beneath guide plate (3) together.

The same shims will be used for assembly. The

following removal procedure is applicable to both sides

of the idler and for both front track idlers.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |