|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

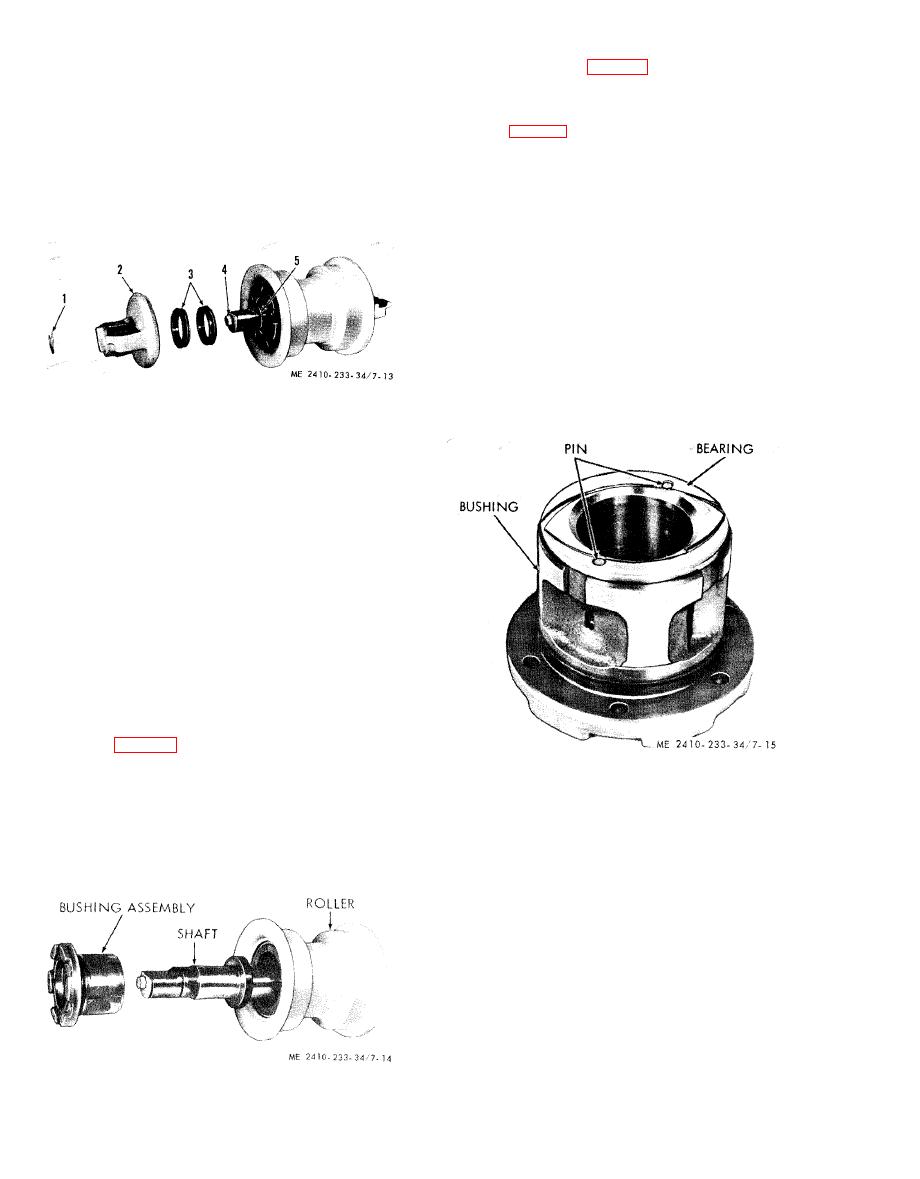

(6) The bearing (fig. 7-15) can be pressed out

NOTE

and replaced provided the bushing is not damaged.

To facilitate removal of the front or rear rollers, the

second roller from either end should be removed and

NOTE

rolled back on the rails out of the way.

Install new bearings if the shaft clearance exceeds that

given in table 1-5.

CAUTION

Do not extend any part of body, legs or

(7) Press the bearing out of the bushing and

arms, between the track and rollers, or

cut off the projecting pins with a hacksaw.

between ground and track during

(8) Smooth the face of bushing with a file.

removal of lower track rollers.

(9) Press the new bearing into place making

certain the lubricant holes are aligned.

(10) Drill two 9/32 inch holes 13/16 inch

deep through the flange of the bearing and into the

wall of the cast iron bushing.

CAUTION

Be sure the holes do not interfere with

lubrication grooves in the face of the

bearing flange.

(11) Install the proper pins so they do not

extend above the face of the bearing.

(12) Smooth the face of the bearing flange.

1

Ring

2

Collar

3

Metal floating ring seals

4

Plug

5

Preformed packing

b. Disassembly.

(1) Remove the ring (1).

(2) Remove the collar (2), the metal floating

ring seals (3), the plug (4) and the preformed

packing ( 5).

CAUTION

The two metal floating ring seals (3)

should be taped together so they will

not become intermixed with seals from

other rollers.

(3) The other end of the roller is disassembled

in the same manner.

(4) Remove the bolts which secure the bushing

assembly (fig. 7-14) to the roller.

(5) The bushing assembly can be pressed out

of the roller by supporting the roller and pressing

c. Cleaning.

on the end of the shaft. The bushing assembly can

(1) Clean all parts using cleaning solvent (Fed.

then be removed from the shaft. Insert the shaft

Spec. P-D-680) and wipe dry with a lint-free cloth.

back into roller and repeat the procedure to press

(2) Remove all dirt and rust from the floating

the bushing assembly from the-opposite end.

ring seal mounting grooves. Grooves must be clean,

smooth and dry.

(3) Wash protective coating from new ring

seals with cleaning solvent.

d. Inspection and Repair.

(1) Inspect the track rollers for damage and

wear. When the contact surface of the roller is worn

from 8.38 to 8.00 inches in diameter, the roller will

be repaired by welding an overlay on the wear

surface. Rollers worn to a diameter of 8.00 inches

or less, or rollers uneconomical to repair, will be

replaced. The diameter of a new roller is 8.75

inches.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |