|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

c. Cleaning.

(7) Install the floating ring seals in the end

collar (2) and seal support (3) as outlined in

(1) Clean all parts using cleaning solvent (Fed.

Spec. P-D-680) and wipe dry with lint-free cloth.

(2) Remove all dirt and rust from the floating

(8) Replace the preformed packing on the

shaft, install the end collar on the shaft and install

ring seal mounting grooves. Grooves must be clean,

the retaining ring.

smooth, and dry.

(3) Wash protective coating from new ring

NOTE

seals with cleaning solvent.

Lubricate the preformed packing on the shaft (1) with

d. Inspection and Repair.

liquid soap before installing the end collar (2).

(1) Inspect the carrier rollers for damage and

(9) Lubricate the carrier roller.

wear. When the contact surface wear or flange wear

(10) Reinstall the carrier roller and adjust the

exceed inch, or the roller is otherwise damaged,

track (TM 5-2410-233-20).

it will be replaced.

(2) Inspect the roller bearings for corrosion,

roughness, and wear. Replace bearings which are

pitted, rough, or worn excessively.

(3) Inspect the metal floating ring seals for

dam age and proper wear pattern. Replace seals

which are pitted, grooved, scratched across the seal

surface, or which show an uneven wear pattern.

Seals must be replaced in sets.

(4) Replace all toric sealing rings. Do not reuse

toric seal rings.

e. Reassembly and Installation.

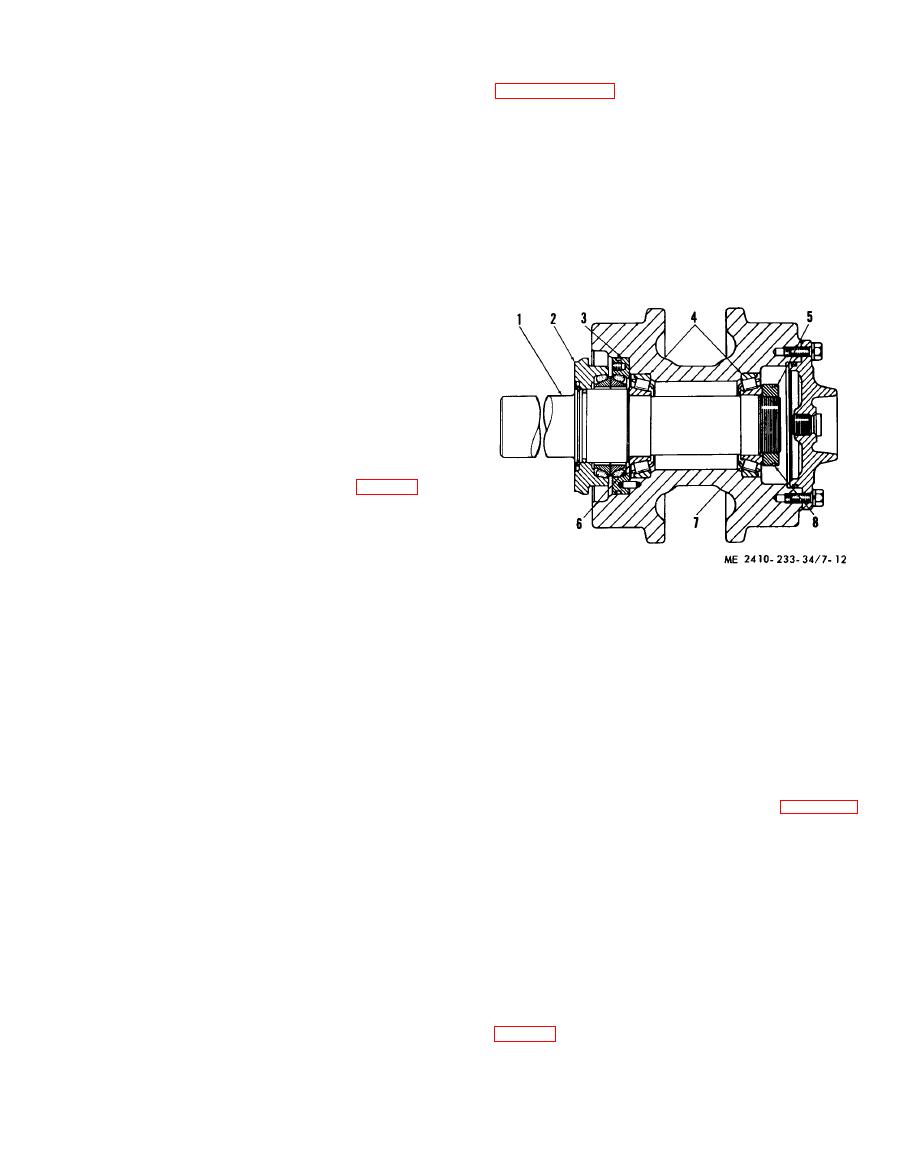

(1) Heat the bearing cone (6, fig. 7-12) and

install it on the shaft so that the inner race seats on

the raised section of the shaft.

(2) Install the bearing outer races (4) in the

roller.

(3) Install the shaft in the roller, heat the

bearing cone (7) and install it on the shaft, and

1

Shaft

install the spanner nut.

2

End collar

(4) Tighten the nut (5) until all bearing end

3

Seal support

clearance is removed and a slight drag can be felt

4

Outer races

on the bearings when the shaft is rotated; then

5

Nut

6

Bearing cone

back off the nut until the nearest aligning hole

7

Bearing cone

aligns with the slot in the shaft and install the

8

Lockring

lockring (8).

( 5 ) Install the end cover. Replace the

preformed packing if, it is damaged.

7-3. Track Rollers

CAUTION

a. Removal.

Before installing the end cover, remove

any burrs from the bore of the roller to

(1) Loosen the tracks as outlined in paragraph

7-1.

prevent damage to the preformed

(2) Place a block approximately 12 inches

packing during installation.

high in front of the track and drive the tractor over

CAUTION

the block until the block is beneath the front roller.

Before installing the end cover, remove

any burrs from the bore of the roller to

(3) Place a block approximately 12 inches

high against the track in back of the sprocket and

p r e v e n t damage t o t h e p r e f o r m e d

back the tractor until the track is resting on the

packing during installation.

block under the sprocket and the block under the

(6) Drive the seal support (3) into the roller

idler.

until it seats in the bore. Lubricate the preformed

(4) Push brake pedals down and apply brake

packing on support (3) with liquid soap to facilitate

lock.

installation.

(5) Remove the bolts from the end collars (2,

NOTE

Be sure the dowel in the support (3) lines up with the

and remove the roller.

milled slot in the roller.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |