|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(5) Install each set of coned disc seal washers

with one outside diameter facing the counterbore in

link (4) and one outside diameter facing spacer (1),

with inside diameters against each other. Install

spacer (1) with beveled edge toward the centerline

of the track.

NOTE

Coned disc seal washers (2 and 3) and spacers (1) can

be held in place in the counterbores of master links (4)

with the use of two holding tools. Fabricate the tools to

the dimension given in figure 7-7.

(6) Assemble the tools on master links and

tighten the bolt on each tool to compress seal

washers. Spacers will be flush with inner face of

links when seal washers are properly compressed.

(7) Force the track together until the spacers

and seal washers are held in place by the track

links.

NOTE

If master pin is to be driven in with a sledge hammer,

move the machine forward and drive the track together

until the spacers and seal washers are held in place by

the track links.

(8) Remove the holding tools. Align the holes

and install the master pin.

(9) Install the bolts in the track shoes. Refer to

b. Disassembly.

(1) Remove the cover (6, fig. 7-9) lockring (5)

and nut (4) from the roller (3).

NOTE

Install the track shoe bolt nut with end having the

(2) Loosen the clamping bolts (2) and drive a

0.156 inch corner radii against the track link.

suitable metal wedge into the slot of bracket (1) to

free the carrier roller shaft and remove the bracket.

(10) Adjust the track (para 7-7).

(3) Remove the lockring (4, fig. 7-10) end

7-2. Track Carrier Rollers

collar (3) and metal floating ring seals (2).

CAUTION

a. Removal.

Tape the seals (2) together so they will

(1) Loosen the track as outlined in paragraph

be kept in matched sets. The floating

7-1.

ring seals (2) should always be installed

(2) Lift the track to provide clearance for

in pairs, that is, two new seals together

removal.

or two seals that have previously run

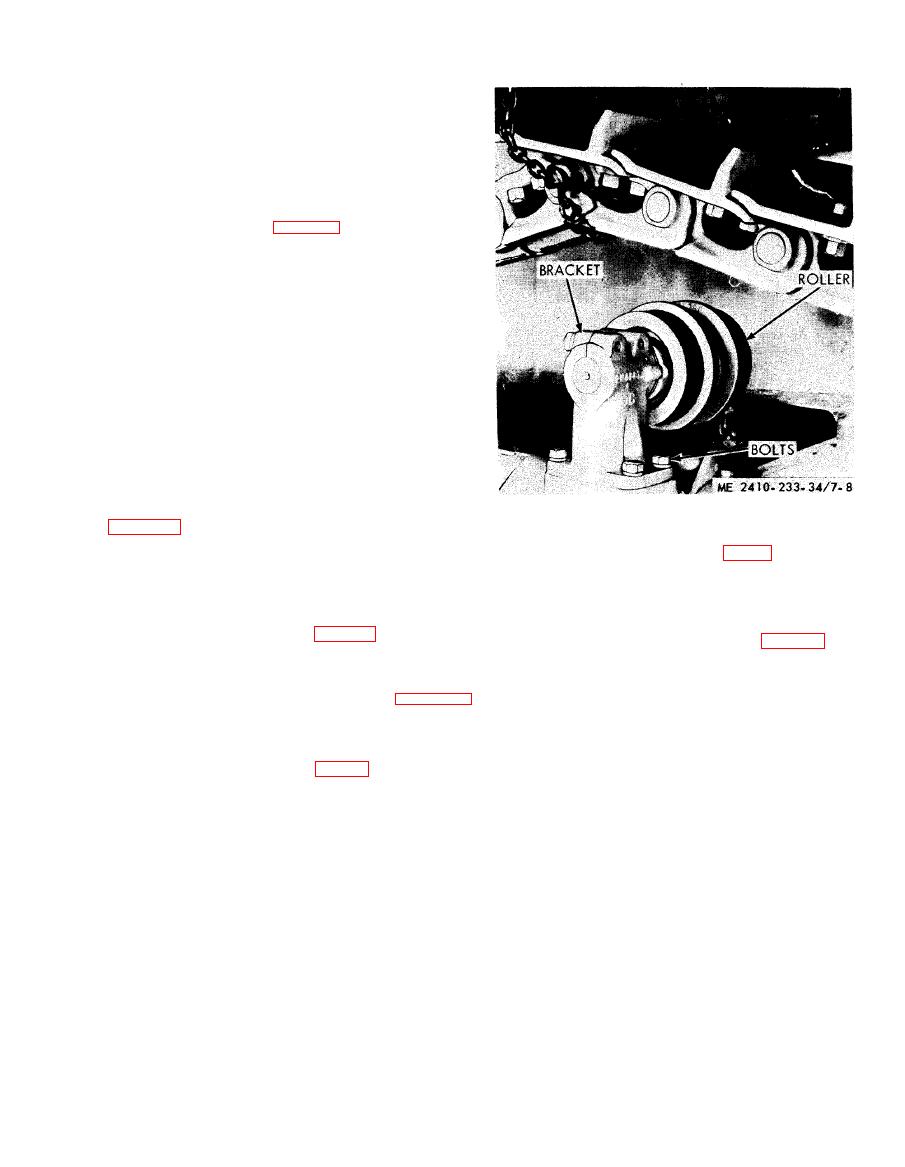

(3) Remove the bracket (fig. 7-8) and roller as

together. Never assemble one new seal

an assembly by removing the (4) bracket to frame

and one used seal together or two seals

mounting bolts.

that have not previously run together.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |