|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(3) Carry the track high enough to clear the

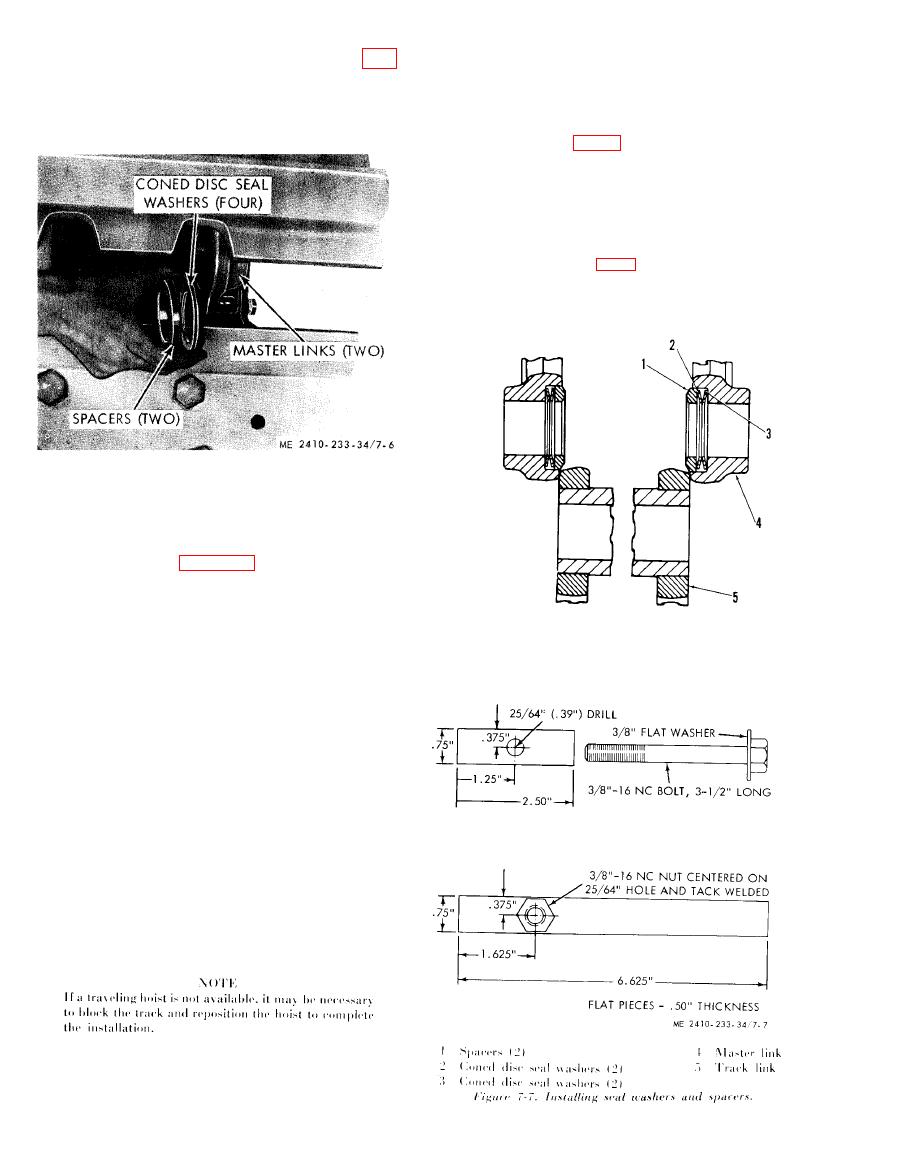

(9) Separate the track and remove spacers (fig.

rollers.

7-6) and coned disc seal washers from links.

(4) Stop with the end of the track slightly

(10) Back the machine slowly, allowing the

behind the front carrier roller and raise the other

track to ride over the carrier rollers and off the

end of the track up around front idler until the

sprocket.

master links (4, fig. 7-7) and links (5) are ap-

proximately 1 inch apart and install coned disc seal

washers (2) and (3) and spacers (1) in master links

(4).

NOTE

If the master pin is to be driven in with a sledge

hammer, block under the first shoe and drive forward

until master links (4, fig. 7-7) and links (5) are ap-

proximately 1" apart and install coned disc seal

washers (2) and (3) and spacers (1) in master links

(4).

b. Inspection and Repair.

(1) Inspect the track links and grousers for

cracks, breaks, and distortion. Repair or replace

broken or damaged links and grousers.

(2) Refer to table 1-5 for track pin and

bushing wear tolerances.

(3) Inspect the track links for wear. When the

links are worn from 4.57 to 4.38 inches in height,

they will be repaired by welding an overlay on the

wear surface. Links worn 4.38 inches or less in

height will be replaced. Link height new is 4.75

inches.

NOTE

Pin boss clearance new is 0.69 inch. Acceptable

pin boss clearance is 0.35 inch.

(4) Inspect the grousers for wear. Grousers

w o r n from 1.93-1.00 inches height will be

repaired by installing applicator bars. Grousers

worn to a height of less than 1 inch, or grousers

uneconomical to repair, will be replaced. New

grouser height is 2.56 inches. Applicator bars will

be installed one time only.

c. Reassembly and Installation.

(1) Back the tractor until the sprocket is just

ahead of the last link of the track.

(2) Attach a hoist to the outside link and raise

the track as the tractor is driven forward.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |