|

|||

|

|

|||

|

Page Title:

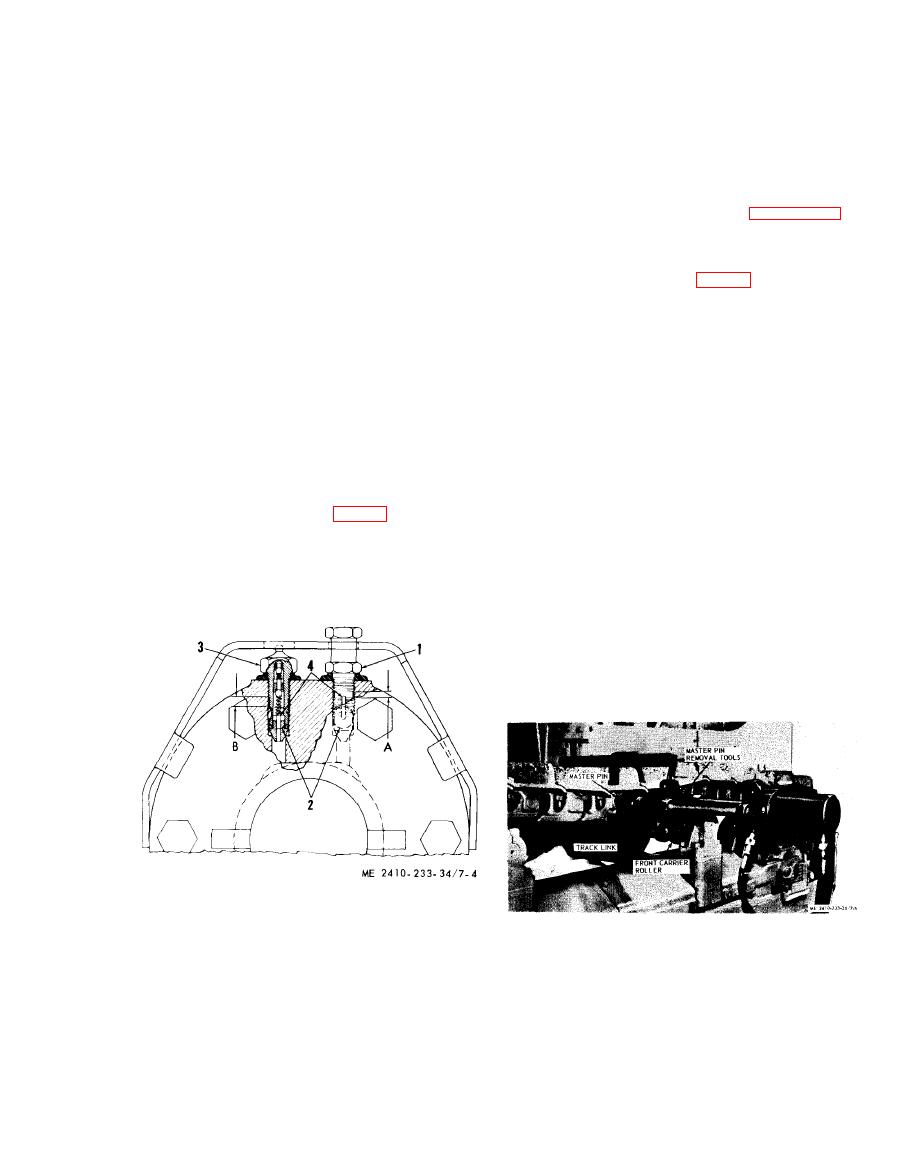

Figure 7-4. Relief valve and fill valve. |

|

||

| ||||||||||

|

|

(6) Loosen fill valve (3) until the unthreaded

WARNING

section (B) is exposed above the flange of the

Because of the hydraulic pressure in the

hydraulic cylinder. The hexagonal shoulder of fill

track adjuster cylinder, never visually

valve (3) will contact the underneath side of the

inspect the vent holes and valves to see

guard. Grease should then escape through slot (4)

if grease is escaping. Always observe the

in the lower section of the threads.

cylinder to see that it moves to the rear

into the recoil spring front pilot.

NOTE

(4) Turn relief valve one turn in a coun-

Detailed information concering the hydraulic track

terclockwise direction and allow grease to escape

adjusting mechanism can be found in paragraph 7-7.

from vent hole just below relief valve. If grease does

(7) Position the master pin above and slightly

not appear when the relief valve is backed off one

behind the front carrier roller.

turn, turn fill valve one turn in a counterclockwise

(8) Install the tools (fig. 7-5) and press the

direction. If grease does not appear at the vent

master pin from the links.

holes, the machine should be started and moved

forward and backward. If grease still does not

NOTE

appear at the vent holes, insert a bar (such as a

An alternate method for master pin removal is as

draw bar pin) between the track and sprocket.

follows: Place a block approximately 12 inches high in

front of the track and drive the machine forward so the

Move the machine backward so the track will be

track shoe below the master pin rides on the block,

forced upward by the bar. This will apply ad-

then using a suitable drive and a sledge hammer, drive

ditional tension to the track and move the front

the master pin out of the links.

idler and track adjusting mechanism to the rear

against tie force of the recoil springs, thus forcing

grease out the vent holes.

(5) If moving the machine does not relieve the

hydraulic pressure, continue loosening relief valve

until the unthreaded section (A, fig. 7-4) is exposed

above the flange of the hydraulic cylinder. The

lower hexagonal shoulder of the relief valve will

contact the underneath side of the guard. Grease

should then escape through slot (4) in the lower

section of threads.

1

Relief valve

2

Vent holes

3

Fill valve

4

Slots

A

and B-Unthreaded sections

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |