|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(5) Rotate the crankshaft in its direction of

dividual fuel pumps and add spacers below the

normal rotation from 30 before top dead center

lifters as necessary to adjust timing.

until the inlet port closes. At this point fuel flow is

k. Setting Fuel Rack.

(1) Remove the rack cover from the front of

reduced to 6 to 12 drops per minute. Zero the dial

the accessory drive housing rear flange (para 5-28).

indicator.

Remove the cover from the rear of the governor

(6) Rotate the crankshaft until the indicator

housing (para 5-10).

reaches maximum value. At this point the piston is

(2) Install a rack setting gage over the front

at top dead center.

end of the fuel rack.

(7) At proper timing, the indicator reading

should be 0.1091 (+0.0040) inch.

(3) Loosely install a plug and push rod in the

governor plug (59, fig. 5-20) hole. Force the speed

i. Checking Fuel Injection Pump Timing (On

limiter away from the plug hole.

Engine, Using a Gage).

(4) Move the governor control lever forward

(1) Locate the top dead center compression

until the stop collar on the fuel rack just touches the

position for the No. 1 piston.

stop bar on the torque spring. If necessary, insert a

(2) Remove the No. 1 fuel injection pump

(subpara c above). Insert a timing gage, into the

0.003 inch feeler gage between the stop and spring

fuel pump bore.

to help determine the point of contact.

(3) Ensure that the higher step of the pump

plunger is slightly above the top surface of the gage

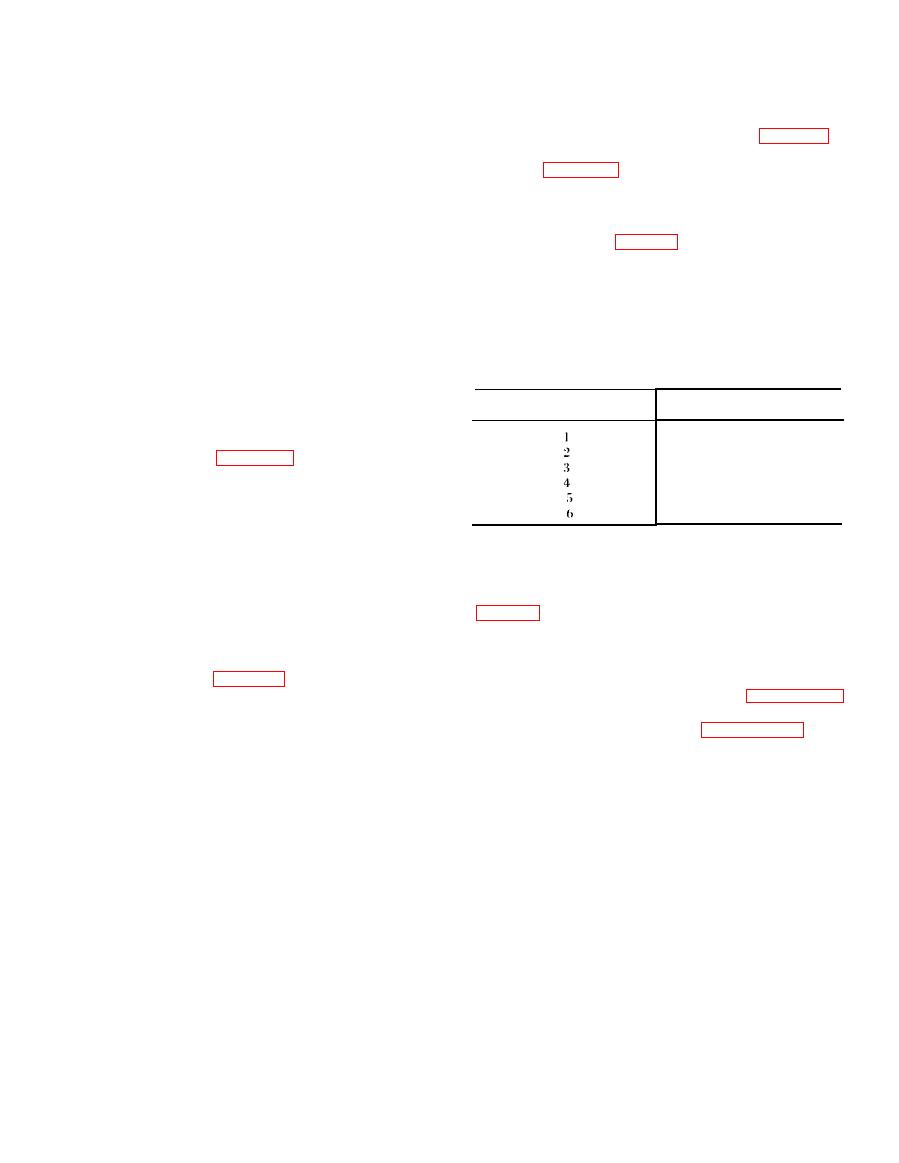

Lifter number

Timing plate

body and that the lower step of the plunger is just

degrees

below the top surface of the gage body. If the gage

179

30'

cannot be correctly positioned, check accessory

59

30'

drive shaft timing (para 5-28).

299

30'

(4) If the gage is correctly installed, the fuel

119

30'

pump is correctly timed.

239 30'

359 30'

j. Setting Fuel Injection Pump Timing (Off

Engine).

(5) Position the rack setting gage from the

NOTE

zero position until it contacts the rack. Total rack

The fuel pump can be adjusted while removed from

travel should be 0.650 inch.

the engine.

(6) To adjust the rack, loosen the locknut (37,

(1) Install a pointer on tbe fuel injection

pump housing.

obtain the desired setting. Tighten the locknut.

(2) Place the timing plate on the drive end of

5-12. Engine Speed Governor

the camshaft and secure.

a. Removal. Remove the engine speed governor

(3) Refer to table 5-1 and select the timing

with the fuel injection pump. Refer to paragraph 5-

plate degree setting for the lifter to be set. Set the

11.

lifter to be set. Set the timing plate by rotating it

b . Disassembly. Refer to figure 5-20 and

counterclockwise until the proper degree setting

disassemble the governor according to sequence of

aligns with the pointer. Lock in position with the

index numbers assigned to figure.

setscrew.

(4) The fuel injection pump timing dimension

is 4.267.5 (+0.0005) inches. Remove the in-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |