|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(12) Assemble wear ring (3, fig. 4-27) to

piston (10).

(13) Install piston (10), washer (2) and nut

(1) on the piston rod. Tighten nut (1) to 750-850

lb-ft.

(14) Install the rubber inner ring of seal

assembly (9) into the groove on the piston ( 10).

(15) Place the outer sealing ring of the seal

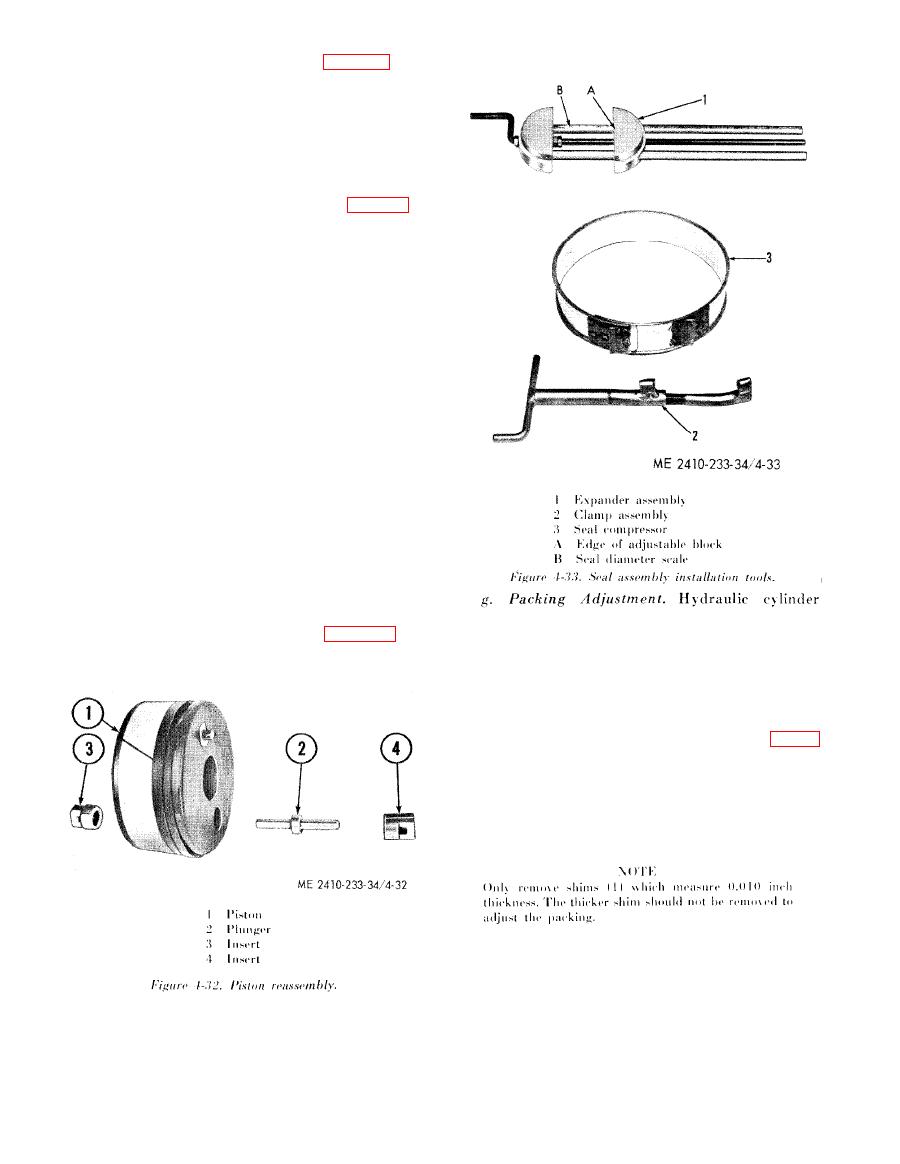

assembly on the expander assembly (1, fig. 4-33).

(16) Stretch until point "A" is slightly above

the 4.75 mark "B" which is the diameter of the

ring.

(17) Back point "A" to the 4.75 mark "B"

and try to lift the seal ring from the expander

assembly (1). If the seal ring will not slip off easily,

rotate the seal ring 900 and stretch as before. When

ring will slip off the expander assembly easily, with

point "A" set at the 4.75 inch mark "B", the ring

can be assembled on the piston, over the rubber

inner ring.

CAUTION

Do not over-stretch the seal ring.

(18) oil the piston, wear ring, seal assembly,

and the inside of the cylinder, and install the seal

compressor (3) and clamp assembly (2) over the

seal assembly. Compress the seal assembly until it

is equal to the od of the piston.

(10) Install the piston assembly into the

cylinder, allowing the seal compressor to shoulder

against the cylinder and be forced off the seal

assembly, as the piston is pushed into the cylinder.

(20) Tighten the cylinder head bolts with the

packing leakage can be caused by wear, cuts,

piston rod fully extended. Refer to table 1-2 for

and/or distortion of the packing. If the cylinder

correct torque values.

leaks around the rod, shims can be removed to

tighten the packing around the rod.

( 1 ) Lower the hydraulically controlled

equipment to the ground to relieve cylinder

pressure.

(2) Remove bolts holding retainer (2, fig. 4-

34) to cylinder head.

(3) Pry or tap retainer out to permit cutting

and removng shims (1).

(4) Remove one shim at a time. If, after

removing two shims, the cylinder still leaks.

disassemble cylinder and replace packing.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |