|

|||

|

|

|||

|

Page Title:

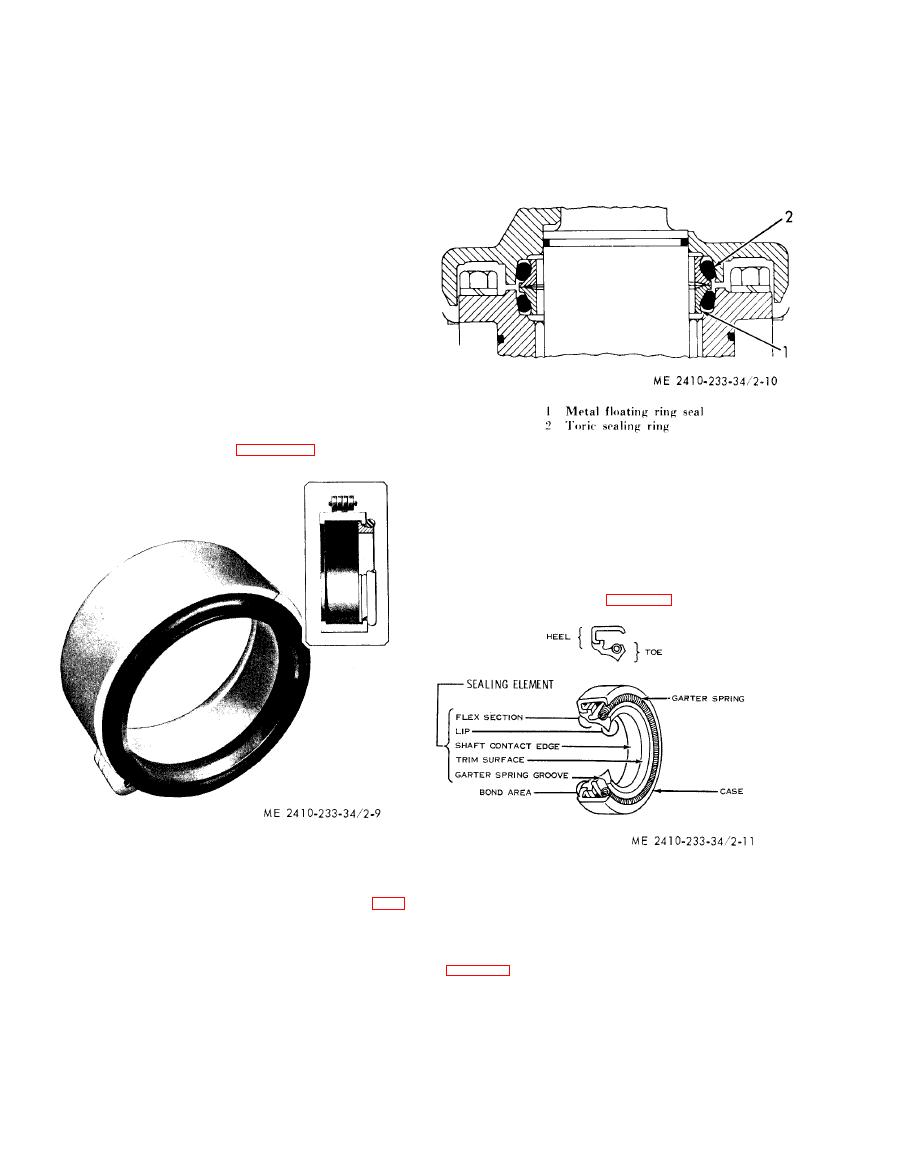

Figure 2-9. Floating seal installation tool. |

|

||

| ||||||||||

|

|

(i) B e f o r e a s s e m b l i n g f l o a t i n g r i n g s e a l s

(d) Handle all parts with care to avoid nicks.

together, wipe faces of seals with lint-free tissue to

File smooth any parts, other than the sealing faces,

remove any foreign material and fingerprints. Place

that have nicks that may make assembly difficult or

one drop of oil on the cleaning tissue and coat the

questionable. Wash used parts. Use a wire brush to

sealing surfaces of the seals. Be careful to prevent

clean dirt or rust from the bore of the seal retainers

any oil from contacting the toric sealing ring or its

to assure they are clean and smooth. Remove all oil

o r the protective coating from floating ring seals

mating

surfaces.

and retainers w i t h a nonflammable cleaning

solvent. Be sure the ramp on the retainers and on

t h e floating ring seals are dry.

(e) C h e c k t h e r a m p s f o r t o o l m a r k s a n d

n i c k s . on used parts, remove dirt or rust deposits

from the ramps. Smooth the surface with emery

cloth.

(f) Install new toric sealing rings or floating

ring seals. Scat the toric sealing ring uniformly in

the relief of the ring seal. Be sure the toric sealing

ring is not twisted. It must set straight against the

lip which keeps it from falling off the floating ring

seal.

(g) Floating seal installation tools are

available for various size seals. A t y p i c a l i n -

s t a l l a t i o n tool is shown in figure 2-9.

seal and toric sealing ring properly positioned.

(2) L i p - t y p e s e a l s .

(a) Generally the toe or spring-loaded lip of

an oil seal faces the oil being sealed or the oil having

the higher pressure. The toe or lip of a grease seal

faces away from the lubricant being sealed. Unless

otherwise specified, use the preceding rules for

i n s t a l l i n g lip-type seals (fig. 2-11).

(h) If an installer tool is not used, install the

toric sealing ring and floating ring seal as an

(b) The main parts of a lip-type seal are the

assembly by pressing on the toric sealing ring (fig.

case,

sealing element, and garter spring. The

2 - 1 0 ) . Use finger pressure only. Be sure the toric

picture illustrates the construction of a simple lip-

scaling ring is seated uniformly in the recess of both

type seal. The cross sections show the terms "heel"

the floating ring seal and the retainer. Make sure it

( f i g . 2 - 1 2 ) a n d " t o e " used to identify the sides of

s e t s in the bore straight and against the lip that

v a r i o u s types of seals.

k e e p s it from falling out of the retainer. DO NOT

USE A SCREWDRIVER OR STICK TO

ASSEMBLE THE TORIC SEALING RING IN

THE RETAINER.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |