|

|||

|

|

|||

|

Page Title:

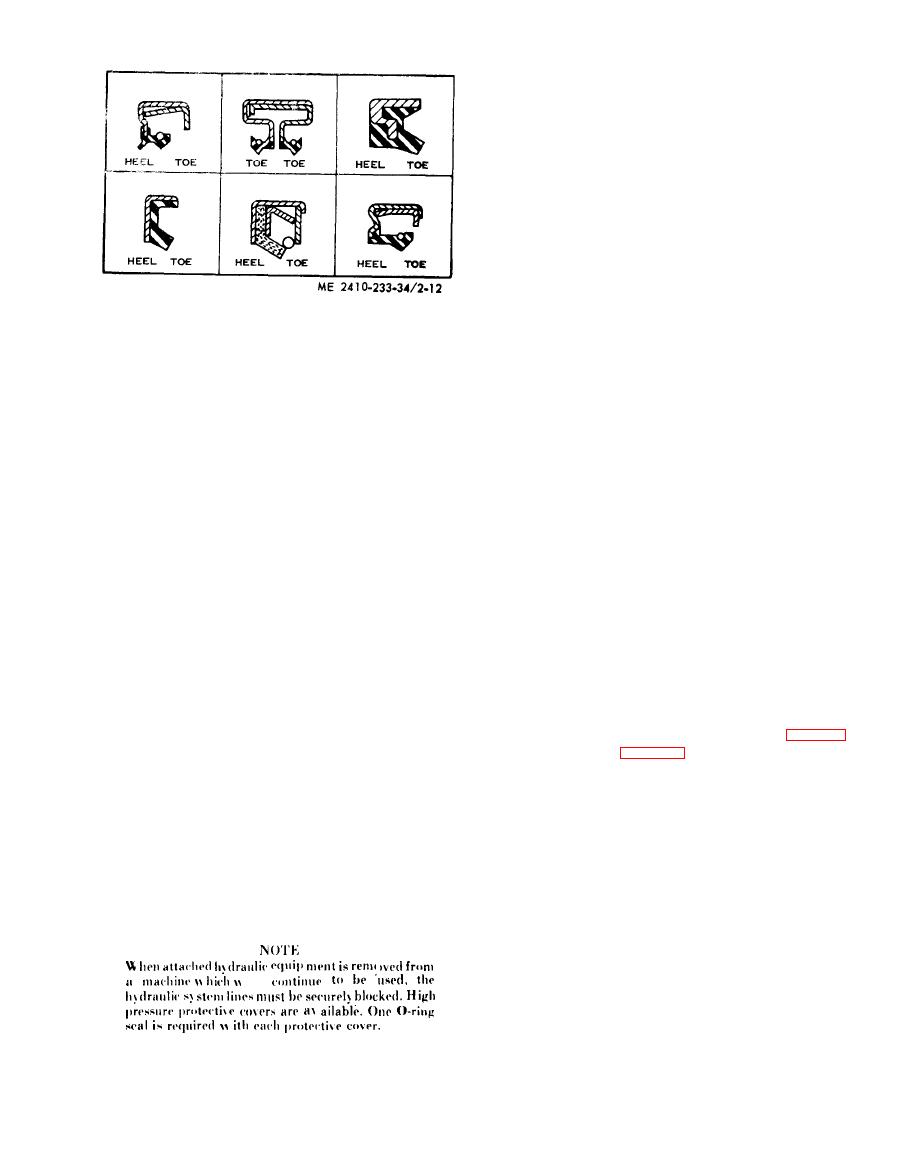

Figure 2-12. Heel and toe type seals. |

|

||

| ||||||||||

|

|

(3) Sealing elements. Inspect all sealing

elements (O-rings, gaskets, etc.), when

disassembling and assembling hydraulic system

c o m p o n e n t s . Install new elements if necessary.

(41 H y d r a u l i c l i n e s .

(a) When installing metal tubes, tighten all

b o l t s finger-tight. Then, in this order, tighten the

b o l t s at the rigid end, the adjustable end, and the

m o u n t i n g b r a c k e t s . A f t e r the tubes are mounted,

install the hoses. Connect both ends of the hose

w i t h all bolts finger-tight. Position the hose so it

does not rub the machine or another hose and has a

m i n i m u m of bending and twisting. Tighten bolts in

both couplings.

(b) Due to manufacturing methods there is a

n a t u r a l curvature to a hydraulic hose. Install the

(c) Lubricate the lips of lip-type seals before

hose so any bend is with this curvature. In case of

i n s t a l l a t i o n . Use the same type lubricant in which

r e p l a c e m e n t hoses with angled-stem and reusable

the seal will be operating. Do not use grease on any

fittings, the hose curvature must be taken into

s e a l except a grease seal.

c o n s i d e r a t i o n when assembling and positioning the

(d) If, during installation, the seal lip must

pass over a shaft that has splines, a keyway, rough

angled stems.

surface or a sharp edge, the lip can be easily

(c) After the hoses are installed, follow this

damaged. Shim stock or other such material can be

procedure: With the diesel engine running, move

formed around the area to provide a smooth surface

the appropriate control levers to move the com-

o v e r which to slide the seal.

ponent to every possible position. Observe the hoses

m. Hydraulic Systems.

d u r i n g the cycle. Then lower the component to the

(1)

Cleanliness.

ground. Shut off the diesel engine and eliminate

(a) W h e n r e m o v i n g c o m p o n e n t s o f a

any twisting, rubbing and/or excessive drooping

hydraulic system cover all openings in both the

of hoses by rotating the stem of the hoses.

component and the machine.

(5) H y d r a u l i c f i t t i n g s .

(b) If evidence of metal or rubber particles

( a ) Fitting bodies with straight threads and

are found in the hydraulic system, flush the entire

O-ring

seals.

system.

1. This type of fitting is used in several

(c) Disassemble and assemble hydraulic

applications. The tube end of the body will vary in

components on a clean surface. Clean all metal

design depending upon the application. However,

parts in a nonflammable cleaning fluid. Then

the installation procedure of the fitting body into its

lubricate all components to aid in assembly.

mating boss will be the same. If the tube end of the

(2) Safety. Before servicing

the hydraulic

fitting body is as illustrated (either elbow (fig. 2-13)

system, NEUTRALIZE THE

HYDRAULIC

o r straight body (fig. 2-14)) a presetting procedure

PRESSURE.

i s necessary to assemble the sleeve onto the tube

PROCEDURE:

before connecting the tube to the end. See ( b )

(a) L o w e r c o m p o n e n t s t o t h e g r o u n d . I n

below.

some instances a removal procedure may require

2 . Place the nut, washer and seal as far

t h e component to be blocked in a certain position.

back on the fitting body as possible. Hold the

(b) With the engine shut off, move the

c o m p o n e n t s in this position and screw the fitting

i n t o its boss until washer just contacts the face of

h y d r a u l i c control levers to all positions to insure

the boss.

t h e r e is no pressure in the system.

(c) P l a c e a l l c o n t r o l l e v e r s i n H O L D

3. Place the fitting assembly in its correct

position.

angular position by turning the body out (coun-

t e r c l o c k w i s e ) , a maximum of 359. Tighten the nut

finger-tight.

ill

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |