|

|||

|

|

|||

|

Page Title:

Blade Tilt Cylinder and Lift Cylinders Drift. |

|

||

| ||||||||||

|

|

TM 5-2410-233-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

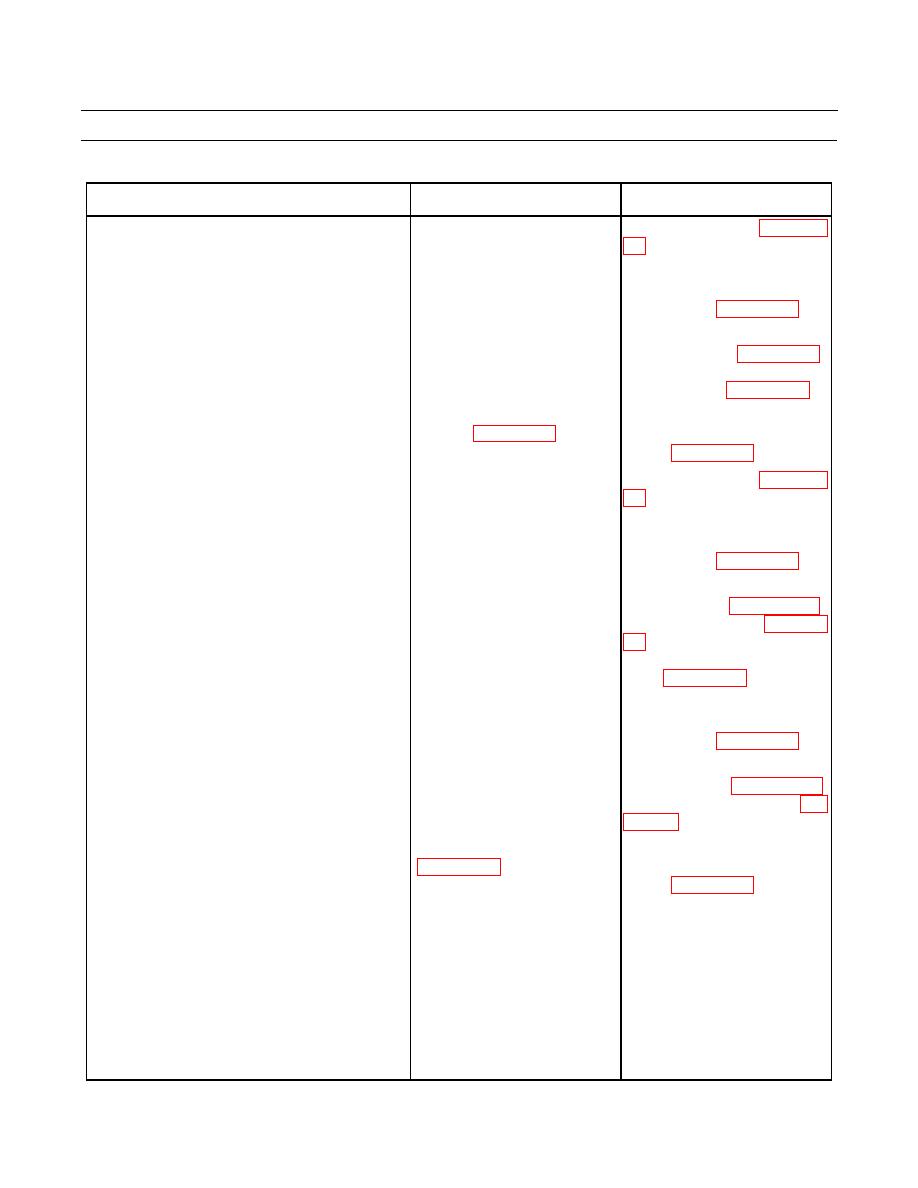

Table 4. Hydraulic System Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Blade Tilt Cylinder and Lift Cylinders Drift. 1. Check oil level in hydraulic Add oil as required (WP 0165

5.

tank.

2. Check hydraulic lines, hoses 1. Tighten loose fittings.

and fittings for signs of leaks 2. Replace damaged lines, hoses

and/or damage.

and fittings (WP 0160 00).

3. Check linkages and control 1. Adjust and/or replace blade

valves for free movement and

control linkage (WP 0152 00)

full travel.

2. Replace main (bulldozer)

control valve (WP 0151 00).

4. Perform Hydraulic System Adjust, repair or replace affected

component as directed by test

results (WP 0167 00).

Blade Tilt or Ripper Lift Circuit is Slow or 1. Check oil level in hydraulic Add oil as required (WP 0165

6.

tank.

Does Not Move.

2. Check hydraulic lines, hoses 1. Tighten loose fittings.

and fittings for signs leaks 2. Replace damaged lines, hoses

and/ or damage.

and fittings (WP 0160 00).

3. Check linkages and control Adjust and/or replace blade

valves for free movement and control linkage (WP 0152 00),

full travel.

ripper control linkage (WP 0153

control valve or ripper control

valve (WP 0151 00).

Ripper Moves Very Slowly/No Down 1. Check hydraulic lines, hoses 1. Tighten loose fittings.

7.

and fittings for signs leaks 2. Replace damaged lines, hoses

Pressure in Lift Circuit (Blade Tilt Circuit

and/or damage.

and fittings (WP 0160 00).

OK).

2. Check linkage and control Adjust and/or replace ripper

valve for free movement and control linkage (WP 0153 00)

full travel.

and/or ripper control valve (WP

Hydraulic Oil is Overheating (Indicated by Perform Hydraulic System Tests Adjust, repair or replace affected

8.

component as directed by test

results (WP 0167 00).

Components).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |