|

|||

|

|

|||

|

Page Title:

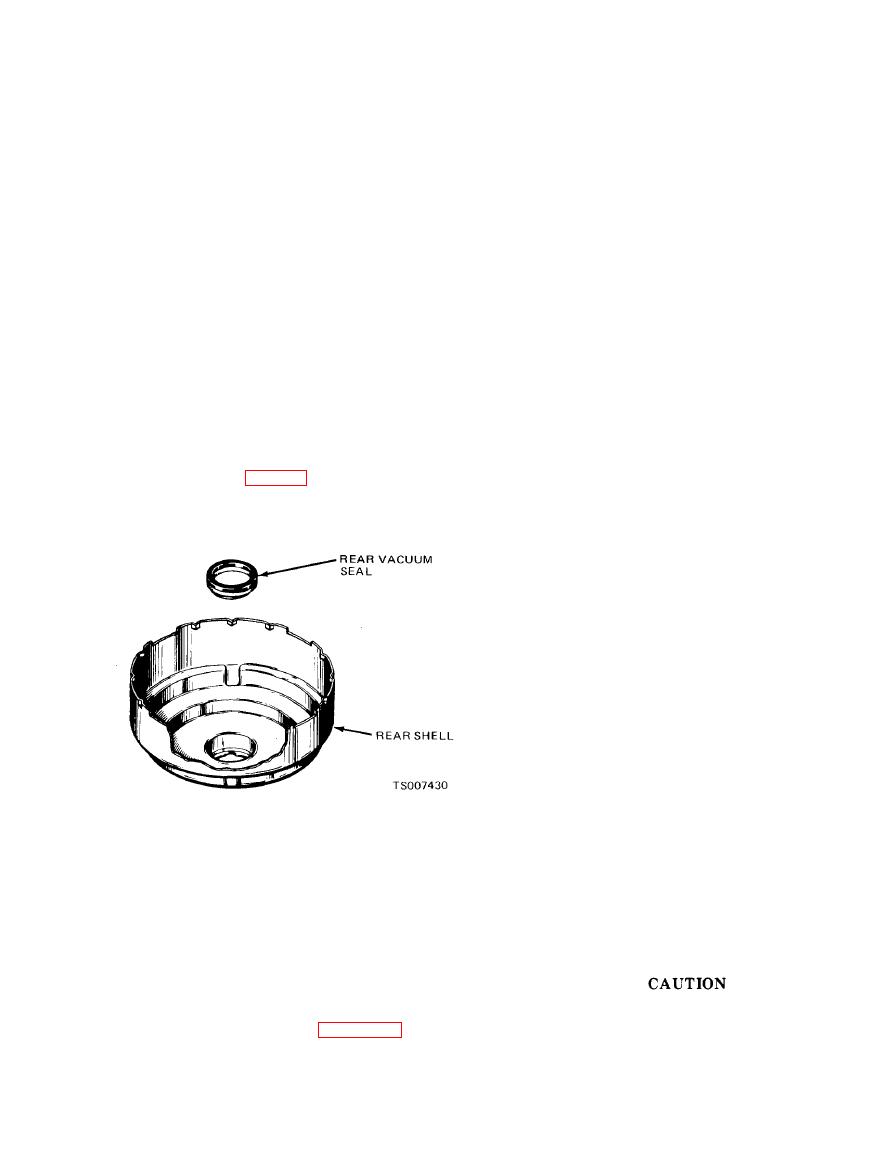

Figure 9-9. Installing Vacuum Seal. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

plunger and, using hands only, screw rear plate

NOTE

DO NOT remove seal unless a new seal is available.

onto front plate hub. To tighten plates, place 1-

1 / 1 6 " hex bar stock in vise and set plate

b. Cleaning.

(1) After disassembly, all metal parts should

assembly, front plate down, on hex bar. Using air

be cleaned in solvent, Federal Specification P-D-

channel slot or rear plate edges, hand torque

680. Plastic parts and rubber parts should be

plates to 120 - 180 in./lbs. Remove plate

cleaned ONLY by wiping with a cloth moistened

assembly from vise. Install rear diaphragm on

in the same type solvent. Care should be taken to

rear plate and over lip of center plate. Assemble

prevent chipping or cracking of plastic parts.

diaphragm spring retainer over rear diaphragm

Replace all rubber parts,

except power

and lip of center plate. Using fingers only, press

retainer onto center plate until it seats against

diaphragms. After parts have been cleaned, use

clean (filtered) dry compressed air to blow dirt

shoulder of center plate.

and solvent out of recesses and internal passages.

(3) Apply talcum powder to inside wall of

c. Inspection. Inspect all parts for damage or

rear shell. Apply hydraulic brake fluid (or

excessive wear. The power diaphragms must be

equivalent) liberally to bearing seal in rear shell.

free of kinks, cracks and tears. Replace any

Apply hydraulic brake fluid (or equivalent)

damaged, worn or chipped parts.

liberally to cutouts around edge of front shell.

d. Assembly.

Clamp fixture base in vise and insert rear shell

studs through matching holes in base. When

(1) If vacuum seal and bearing was removed

from rear shell, press new seal into shell cavity,

assembling the plate and diaphragm assembly in

the rear shell, the lugs on the center plate must be

plastic side first (fig. 9-9), until flat rubber

aligned between the lances on the rear shell.

surface is about 5/16" below flat inside shell

Carefully guide valve housing sleeve through

surface (.305" minimum).

bearing seal in rear shell keeping center plate and

diaphragms in correct alignment. Work outer rim

of front diaphragm into rear shell so that outer

rim is under each of the retaining lances on the

rear shell. Place large diameter end of diaphragm

return spring over front plate hub and position

front shell on spring so that scribe marks on front

and rear shells will be aligned when shells are

twist-locked in place. Place bar wrench over studs

of front shell and then attach clamp bar with hook

bolts to base. Before tightening center bolt, make

certain cut-outs on front shell are aligned with

locks on rear shell. Guide rim of diaphragm into

front shell. Tighten center bolt until edge of front

shell will clear lances on rear shell. Twist front

shell clock wise in relation to the rear shell until

stop is contacted. Remove tools from power

cylinder.

(2) Install front diaphragm on front plate.

(4) Apply hydraulic brake fluid liberally to

Apply a light coat of hydraulic brake fluid to

entire surface of reaction disc and to piston end of

outside surface of front plate hub and liberally to

hydraulic pushrod. Place reaction disc on piston

the seal in the center plate hub. Carefully guide

end of pushrod. Apply Bendix Type "O"

center plate and seal assembly, seal side first,

Lubricant (or equivalent) sparingly on shaft of

onto front plate hub. Apply hydraulic brake fluid

pushrod, keeping lubricant away from adjusting

lightly to the front and rear bearing surfaces of

screw end of pushrod.

the valve plunger, being careful not to get any

lubricant on the rubber grommet inside the

Lubricant must not be allowed to get on

plunger. Assemble valve plunger return spring on

adjusting screw or threads.

valve plunger as shown in figure 9-6, and set

(5) Insert pushrod with reaction disc stuck

spring and plunger in recess of front plate hub,

to it into reaction disc hub of front plate. Twist

grommet side up. Place vacuum seal firmly

and press on pushrod to make certain disc is

against shoulder on outside of front plate hub. Set

seated firmly. Assemble seal, support plate side

rear plate, threaded bore down, over valve

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |