|

|||

|

|

|||

|

Page Title:

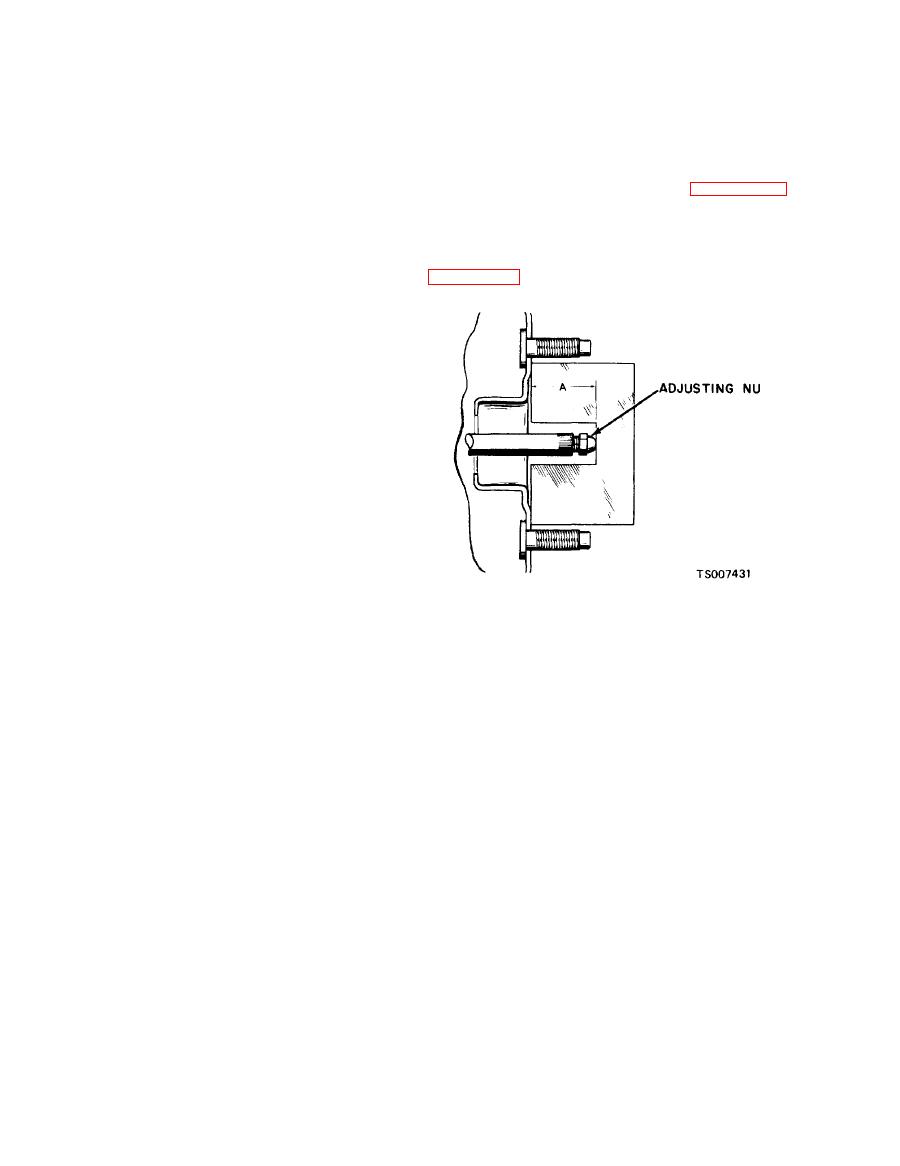

Figure 9-10. Adjusting Pushivd. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

first, over adjusting screw end of pushrod. Press

guard. Press guard against valve housing and

seal into cavity in front shell until seal bottoms. If

seat large end of guard over flange of rear shell.

vacuum check valve was removed, wet new

(8) Unit is now ready for assembly with

grommet in alcohol and press grommet into front

master cylinder (TM 10-3930-633-12). Check

shell, beveled side first. Make certain that

pushrod adjustment as shown in figure 9-10.

grommet is seated in shell. Wet shoulder of check

D i s t a n c e "A" should be 0.880-0.995 inches.

valve in alcohol and assemble check valve in

Adjust this distance by threading nut in or out in

grommet. Press check valve into grommet until

the end of pushrod.

e n t i r e flange of check valve bears against

(9) Installation of the unit is covered in

Chapter 2, Section IV.

grommet.

( 6 ) Wet poppet valve in alcohol and

assemble poppet in valve housing, small diameter

end of poppet first; wet poppet retainer in alcohol

and assemble in housing with flange out. Press in

against retainer to make certain that shoulder of

retainer is positioned inside poppet. Assemble

retainer, valve silencers and filters and valve

return spring over ball end of operating rod in

that order. Wet rubber grommet in valve plunger

and ball end of operating rod with alcohol. Guide

spring, filters and silencers into valve housing

and assemble ball end of operating rod in valve

plunger grommet. Tap end of rod with soft

hammer to lock ball end in grommet. Press filters

into position inside plastic housing and assemble

metal retainer on end of housing, being careful

not to chip plastic.

(7) Wet small diameter of dust guard with

alcohol and assemble dust guard over end of

operating rod, using care to prevent tearing

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |