|

|||

|

|

|||

|

Page Title:

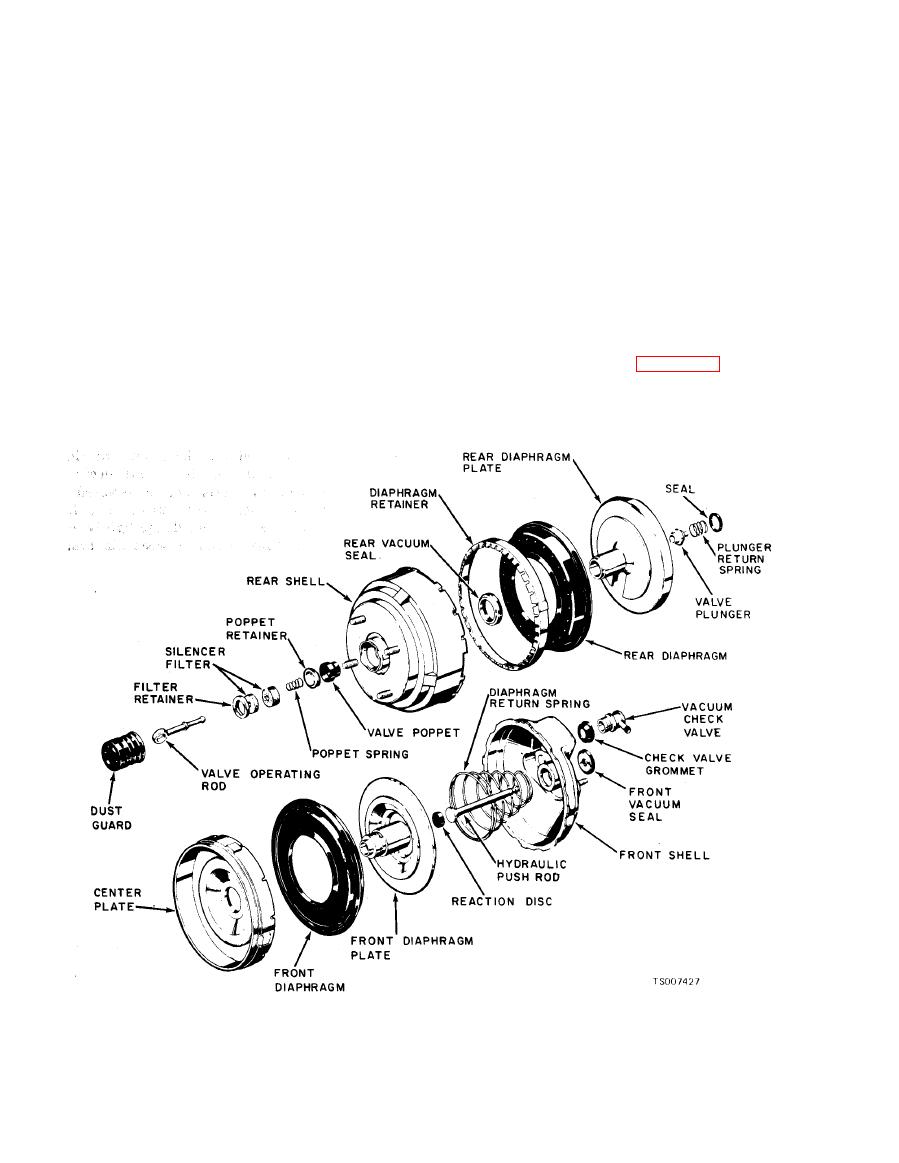

Figure 9-6. Vacuum Power Unit Exploded View. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

The center plate, located between the two

poppet is of the flexible rubber type and is

diaphragms, divides the power unit into four

supported by the valve body hub of the rear

chambers. A long, threaded hub on the front plate

diaphragm plate.

(2) In the released position, the poppet return

slides through the center hole in the center plate

spring holds the poppet against the atmospheric

and is screwed into the hub of the rear plate to

maintain a set separation between the two

port seat (valve plunger). A special type of seal is

diaphragms as the front and rear plates and

used to seal the opening between the valve body

diaphragms move backward and forward. This

sleeve and the rear shell.

(3) Vacuum is supplied to the power brake

front plate hub is sealed by a vacuum seal that is

permanently installed in the stationary center

unit through a vacuum check valve mounted in

plate. Two drilled air passages intersect in the

the front shell. Air for operation is admitted

through silencer-filters within the valve housing.

mounting flange of the master cylinder to provide

At its front end, the power section incorporates

"free breathing" for this cavity during braking.

another special seal to close the opening between

the front shell and hydraulic pushrod.

(4) The hydraulic pushrod is the link between

identification and proceed as follows:

the vacuum power diaphragm and plate assembly

and the hydraulic pistons in the master cylinder.

(1) Scribe across the flanges of both shells

nuts and lockwashers and set master cylinder

and the master cylinder to provide a guide mark

aside.

for assembly. Remove master cylinder attaching

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |