|

|||

|

|

|||

|

Page Title:

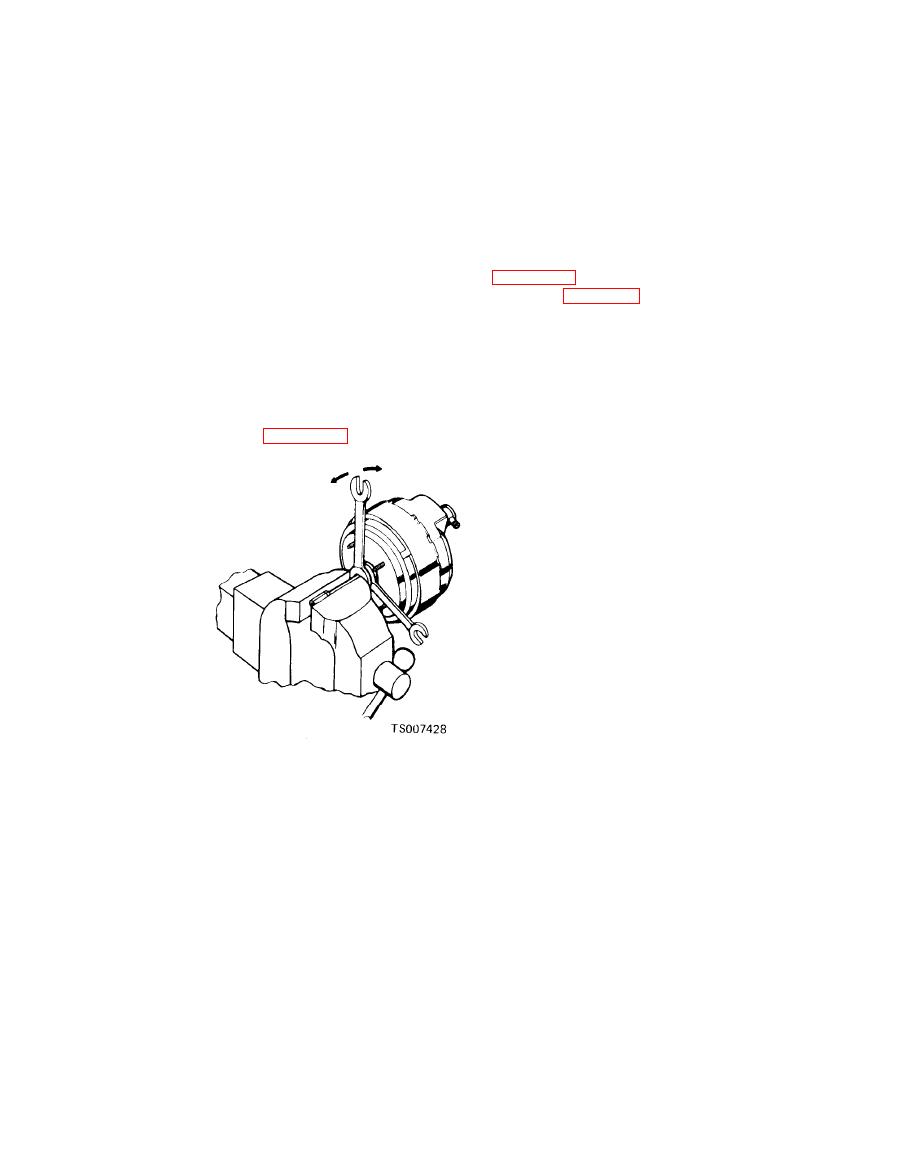

Figure 9-7. Removing Value Rod. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

CAUTION

NOTE

Do not disturb adjustment screw on end of hydraulic

When separating valve rod from

pushrod.

plunger, hold power section to prevent it

(2) Remove hydraulic pushrod from front

from falling to the floor.

shell of power section and then remove front

(4) Use care when prying with wrenches to

vacuum seal from pushrod. Wet valve rod eye and

avoid damage to plastic valve hub. Remove valve

small diameter of dust guard with alcohol and

rod from vise. Carefully pry retainer off end of

then remove dust guard from valve rod and hub of

valve hub. Do not chip or crack plastic. Remove

rear shell. Pull vacuum check valve straight out

valve return spring, poppet retainer and poppet.

of grommet in front shell.

(5) Make up a removal tool as shown in

(3) Remove air filter-silencers from valve

hub. With operating rod in vertical position,

shown in figure 9-8, and insert rear shell studs in

squirt alcohol down rod to wet rubber grommet in

matching holes in base (three or four studs as

valve plunger at ball end of valve rod. Clamp

required). Place flat bar wrench over studs of

valve in soft-jawed vise. Leave just enough space

front shell and align top clamp bar with base.

between steel retainer on plastic valve hub and

Attach hook bolts of top clamp bar to holes at

side of vise jaw for two medium sized open end

opposite ends of base. Tighten T-handle center

wrenches. Use wrench nearest vise as a pry to

bolt just enough to compress shells and free

force valve plunger (and power section) off ball

twelve lanced locks around shell edges. Turn flat

end of valve rod. See figure 9-7.

bar wrench counterclockwise until cut-outs on

front shell are aligned with locks on rear shell.

Unscrew center bolt. Shells should begin to

separate as load on center bolt is released. If

shells do not separate, check cut-out and lock

alignment and then tap shell flange lightly with

soft hammer to break bond between diaphragm

and shells.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |