|

|||

|

|

|||

|

Page Title:

Figure 6-44. Typical Bearing Failures. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

twisted rods will disturb the action of the entire

6-32. Main and Connecting Rod Bearings

piston, rings, and connecting rod assembly and

Cleaning and Inspection

may be the cause of excessive oil consumption.

a. Cleaning. Clean the bearing inserts and caps

(5) Inspect the connecting rods for signs of

thoroughly in solvent, and dry them with com -

fractures and the bearing bores for out-of-round

pressed air. Do not scrape gum or varnish

and taper. If the bore exceeds the maximum limit

deposits from bearing shells.

and /or if the rod is fractured, it should be

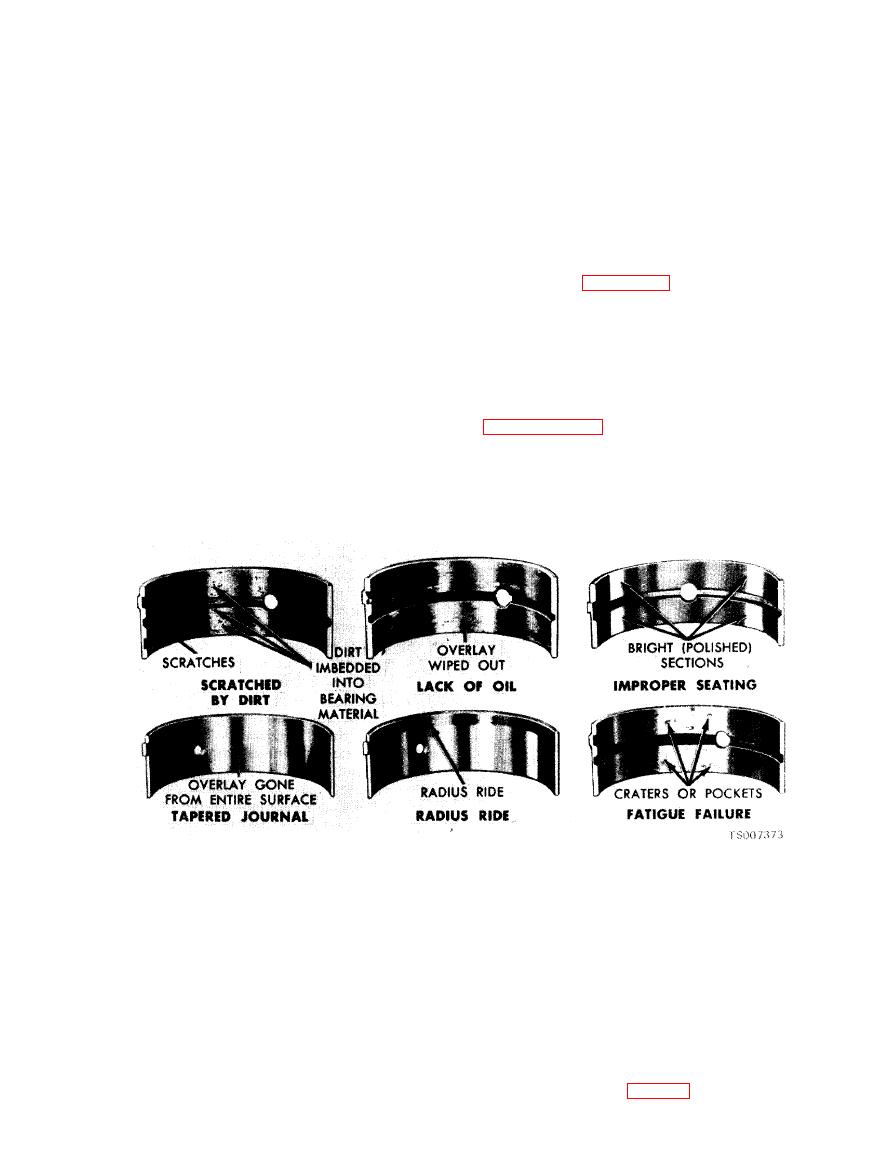

b. Inspection. Inspect each bearing carefully.

replaced.

Bearings that have a scored, chipped, or worn

(6) On connecting rods that have a piston

surface should be replaced. Typical examples of

pin bushing, check the piston pin to connecting

bearings that should be replaced and the causes

rod bushing clearance. Replace the connecting rod

are shown in figure 6-44. The copper-lead bearing

if the bushing is so worn that it cannot be reamed

base may be visible through the bearing overlay.

or honed for an oversize pin.

This does not mean that the bearing is worn. It is

(7) Check the ID of the connecting rod

not necessary to replace the bearing if the bearing

piston pin bore. Replace the connecting rod if the

clearance is within recommended limits. Check

pin bore is not within specifications. Replace

the clearance of bearings that appear to be

defective connecting rod nuts and bolts.

satisfactory with Plastigage. Fit new bearings

(8) After the connecting rods are assembled

following the recommended procedure in

to the piston, check the rods for bend or twist on a

suit able alignment fixture. F o l l o w the in-

structions of the fixture manufacturer. If the

bend and/or twist exceeds specification, the rod

must be straightened or replaced.

with a standard bearing to obtain the proper

6-33. Fitting Main and Connecting Rod Bearings

clearance.

a. Set-up.

(2) If fitting a main bearing, position a jack

( 1 ) Clean crankshaft journals. Inspect

.

under counterweight adjoining bearing which is

journals and thrust faces (thrust bearing) for

being checked. Do not place jack under front post

nicks, burrs or bearing pick-up that would cause

of crankshaft. Support crankshaft with jack so its

premature bearing wear. When replacing stan-

weight will not compress Plastigage and provide

dard bearings with new bearings, it is good

an erroneous reading,

practice to fit the bearing to minimum specified

b. Use of Plastigage.

clearance. If the desired clearance cannot be

(1) Place a piece of Plastigage on bearing

obtained with a standard bearing, try one-half of

surface across full width of bearing cap and about

an 0.001 or 0.002 inch undersize in combination

1/4 inch off center (fig. 6-45).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |