|

|||

|

|

|||

|

Page Title:

Figure 6-31. Piston Ring Gap Spacing. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(3) Be sure to install the pistons in the same

cylinders from which they were removed or to

which they were fitted. The connecting rods and

bearing caps are numbered from 1 to 6 beginning

at the front of the engine. The number on the

connecting rod and bearing cap must be on the

same side of rod when installing in the cylinder

bore. If a connecting rod is ever transferred from

one cylinder block to another or from one cylinder

to another, new bearings should be fitted and the

connecting rod s h o u l d be renumbered to

correspond with the new cylinder number.

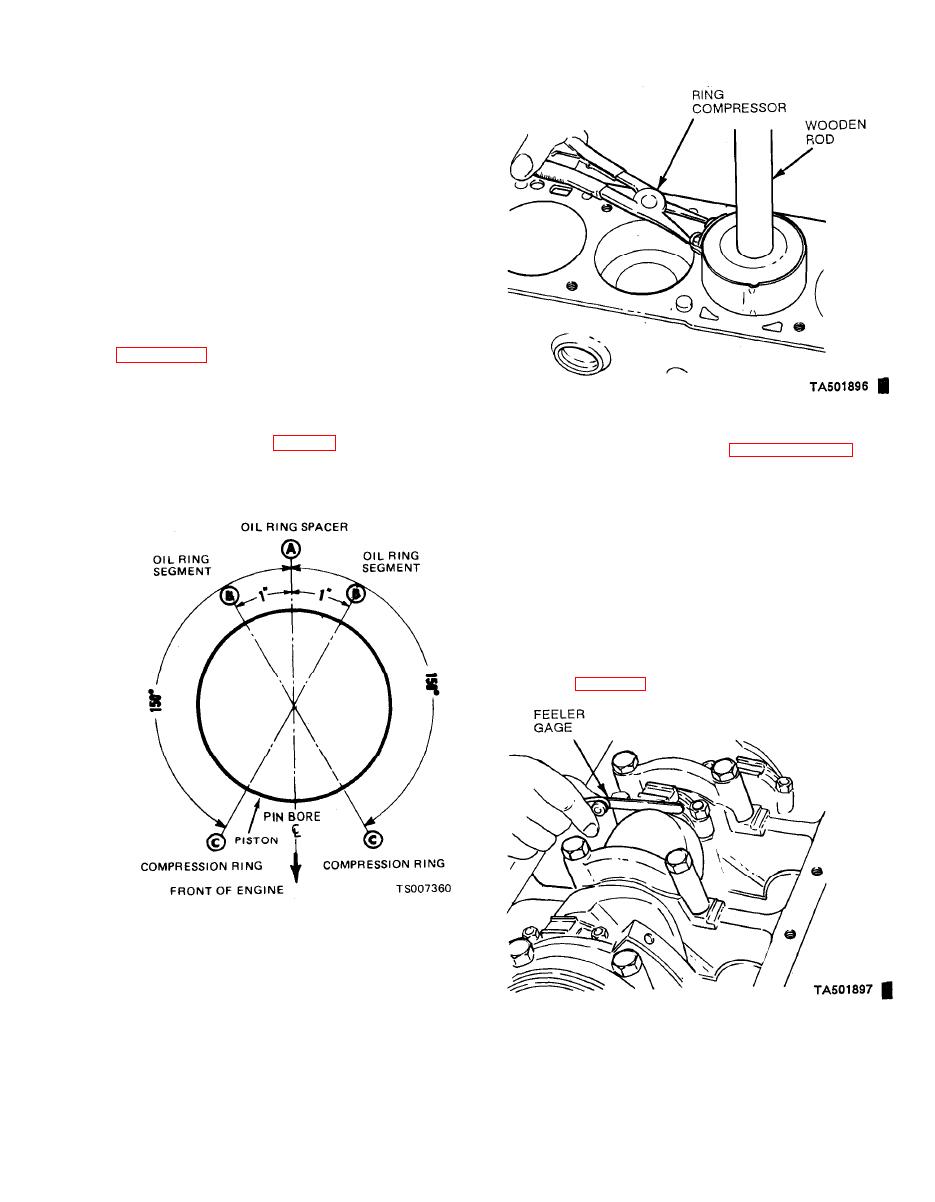

(4) Make sure the ring gaps are properly

spaced around the circumference of the piston

ring compressor on the piston. Make sure that the

indentation in the head of piston is toward the

front, then push the piston into its bore with the

handle end of a hammer until it is slightly below

(5) Check the clearance of each bearing

the top of the cylinder (fig. 6-32). Be sure to guide

following the procedure under paragraph 6-33,

the connecting rods to avoid damaging the

Connecting Rod Bearing Replacement.

crankshaft journals.

(6) After the bearings have been fitted, apply

a light coat of engine oil to the journals and

bearings.

(7) Turn the crankshaft throw to the bottom

of its stroke, then push the piston all the way

down until the connecting rod bearing seats on

the crankshaft journal. Install the connecting rod

cap. Torque the nuts to specifications.

(8) After the piston and connecting rod

assemblies have been installed, check the con-

necting rod side clearance on each crankshaft

journal (fig. 6-33 ). Side clearance should be

0.0060 to 0.0130 inches.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |