|

|||

|

|

|||

|

Page Title:

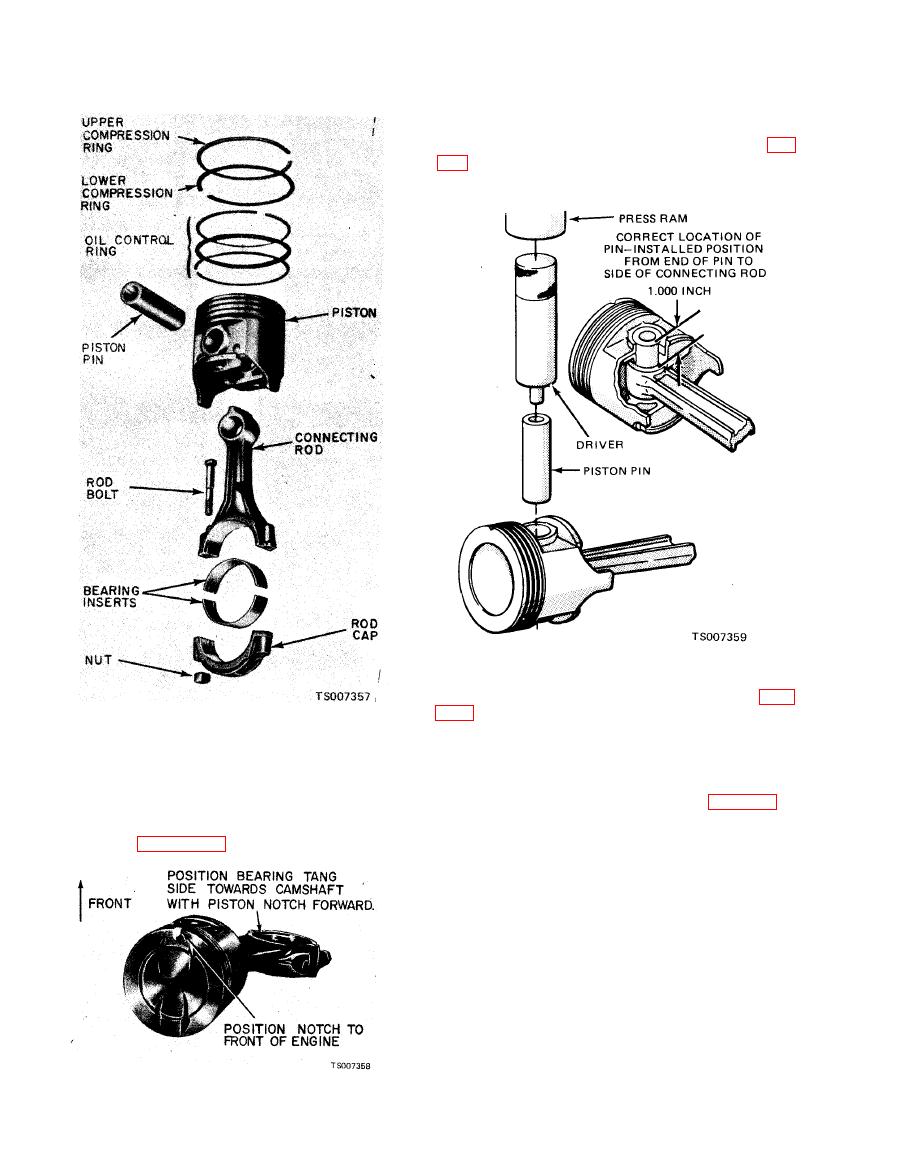

Figure 6-28. Piston and Connecting Rod Assembly. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(2) Start the piston pin in the piston and

connecting rod. Using an arbor press, press the

piston pin through the piston and connecting rod

until the pin is centered in the connecting rod (fig.

6-30) .

(3) Check the end gap of all piston rings (para

instructions contained on the piston ring package

and install the piston rings.

b. Assembly.

(4) Check the ring side clearance of the

(1) Apply a light coat of engine oil to all

compression rings wit h a feeler gage inserted

parts. Assemble the piston to the connecting rod

between the ring and its lower land (fig. 6-27).

with the bearing tang side of the connecting rod

The gage should slide freely around the entire ring

and the indentation notch in the piston positioned

circumference without binding. Any wear that

as shown in figure 6-29.

occurs will form a step at the inner portion of the

lower land. If the lower lands have steps, the

piston should be replaced.

(5) Be sure the bearing inserts and the

bearing bore in the connecting rod and cap are

clean. Foreign material under the inserts will

distort the bearing and cause a failure. Install the

bearing inserts in the connecting rod and cap with

the tangs fitting in the slots provided.

c. Installation.

(1) Clean the oil pump inlet tube screen and

the oil pan and block gasket surfaces.

(2) Oil the piston rings, pistons and cylinder

walls with light engine oil.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |