|

|||

|

|

|||

|

Page Title:

Fitting Pistons and Rings to Bore |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

6-27. Fitting Pistons and Rings to Bore

Pistons are available for service replacement in

the standard size as well as in 0.020, 0.030 and

0.040 inch oversizes. All pistons are matched for

weight, regardless of size. Standard. pistons are

coded red or blue, or have "0.003 OS" stamped on

the dome. Refer to table 6-5 for dimensions.

a. Fitting Pistons.

(1) Measure the cylinder bore and select the

piston to assure the proper clearance. When the

bore diameter is in the lower one-third of the

specified range, a red piston should be used.

When the bore diameter is in the middle one-third

a blue piston should be used. When the bore

diameter is in the upper one-third, the 0.003 OS

piston should be used.

(2) Measure the piston diameter to ensure

that the specified clearance is obtained. It may be

necessary periodically to use another piston

(within the same grade size) that is either slightly

larger, or smaller, to achieve the specified

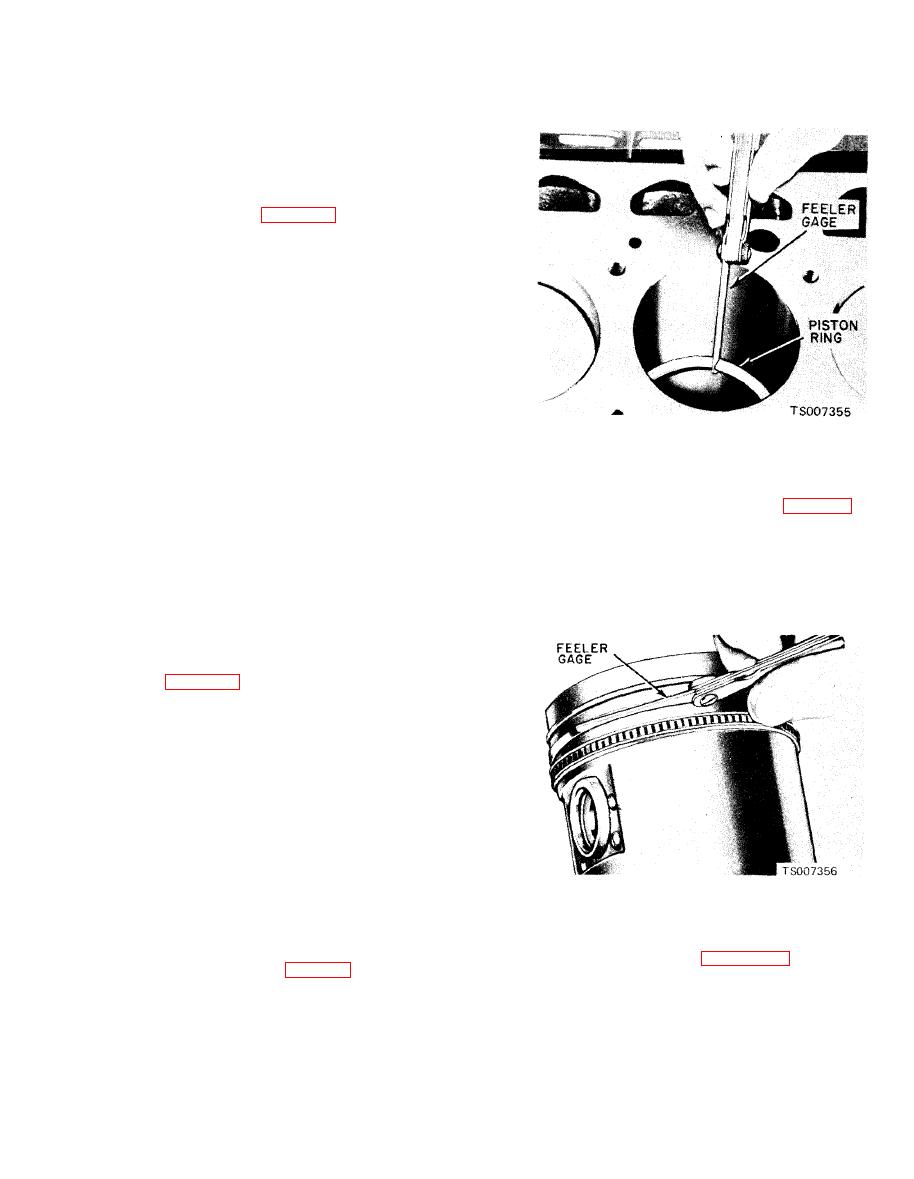

(7) Check the ring side clearance of the

clearance.

compression rings with a feeler gage inserted

(3) If none can be fitted, refinish the cylinder

between the ring and its lower land (fig. 6-27).

to provide the proper clearance for the piston.

The gage should slide freely around the entire ring

(4) When a piston has been fitted, mark it for

circumference without binding. Any wear that

assembly in the cylinder to which it was fitted.

occurs will form a step at the inner portion of the

b. Fitting Rings. If the taper, out-of-round and

lower land. If the lower lands have high steps, the

piston to cylinder bore clearance conditions of the

piston should be replaced.

cylinder bore are within specified limits, new

piston rings will give satisfactory service. If new

rings are to be installed in a used cylinder that has

not been refinished, remove the cylinder wall

glaze (para 6-24, Refinishing Cylinder Walls). Be

sure to clean the cylinder bore thoroughly.

(1) Calculate the size piston to be used by

taking a cylinder bore check, or use the properly

fitted piston, determined in subparagraph a.

(2) Select the proper ring set for the size

cylinder bore.

(3) Position the ring in the cylinder bore in

which it is going to be used.

(4) Push the ring down into the bore area

where normal ring wear is not encountered.

(5) Use the head of a piston to position the

ring in the bore so that the ring is square with the

cylinder wall. Use caution to avoid damage to the

ring or cylinder bore.

a. General. The piston, connecting rod and

(6) Measure the gap between the ends of the

related parts are shown in figure 6-28. Check the

ring with a feeler gage (fig. 6-26). If the ring gap

fit of a new piston in the cylinder bore before

is less or greater than the specified limits, try

assembling the piston and piston pin to the

another ring set.

connecting rod, following the procedures in

subparagraph b. The piston pin bore of a con-

necting rod and the diameter of the piston pin

must be within specifications.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |