|

|||

|

|

|||

|

Page Title:

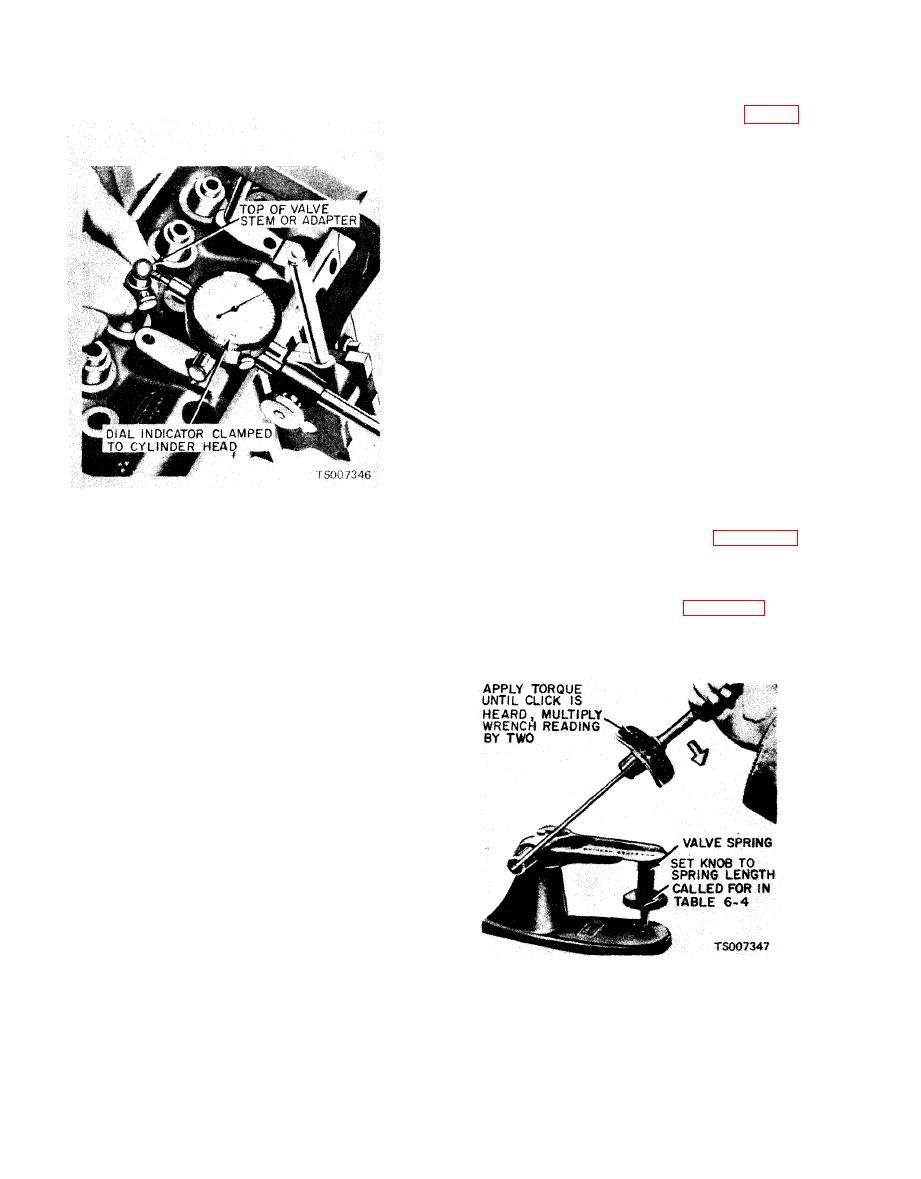

Figure 6-17. Checking Valve Stem Clearance. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

the pits and grooves. If the edge of the valve head

16), replace the valve as the valve will run too hot

in the engine.

(2) The interference fit of the valve and seat

should not be lapped out.

(3) Remove all grooves or score marks from

the end of the valve stem, and chamfer it as

necessary. Do not remove more than 0.010 inch

from the end of the valve stem.

(4) If the valve and/or valve seat has been

refaced, it will be necessary to check the clearance

between the rocker arm pad and the valve stem

with the valve train assembly installed in the

engine.

b. Select Fitting Valves. If the valve stem to

valve guide clearance exceeds the wear limit,

ream the valve guide for the next oversize valve

stem. Valves with oversize stem diameters of

0.003, 0.015 and 0.030 inch are available for

service. Always reface the valve seat after the

valve guide has been reamed.

a. Checking Spring Pressure. Check the valve

(6) Install the tool on the valve stem until it

spring for proper pressure as shown in figure 6-18

is fully seated, and tighten the knurled setscrew

at the specified spring lengths. Weak valve

firmly. Permit the valve to drop away from its

springs cause poor performance; therefore, if the

seat until the tool contacts the upper surface of

pressure of any spring is lower than the wear

the valve guide.

limit, replace the spring, See table 6-4 for

(7) Position the dial indicator with its flat tip

dimensions and readings.

against the center portion of the tool's spherical

section at approximately 90 degrees to the valve

stem axis. Move the tool back and forth in line

with the indicator stem. Take a reading on the

dail indicator without removing the tool from the

valve guide upper surface. Divide the reading by

two, the division factor for the tool.

a. Machining. The valve refacing operation

should be closely coordinated with the valve seat

refacing operations to that the finished angles of

the valve face and of the valve seat will be to

specifications and provide a compression tight fit.

Be sure that the refacer grinding wheels are

properly dressed.

(1) If the valve face runout is excessive

and/or to remove pits and grooves, reface the

valves to a true 44 degree angle. Remove only

enough stock to correct the runout or to clean up

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |