|

|||

|

|

|||

|

Page Title:

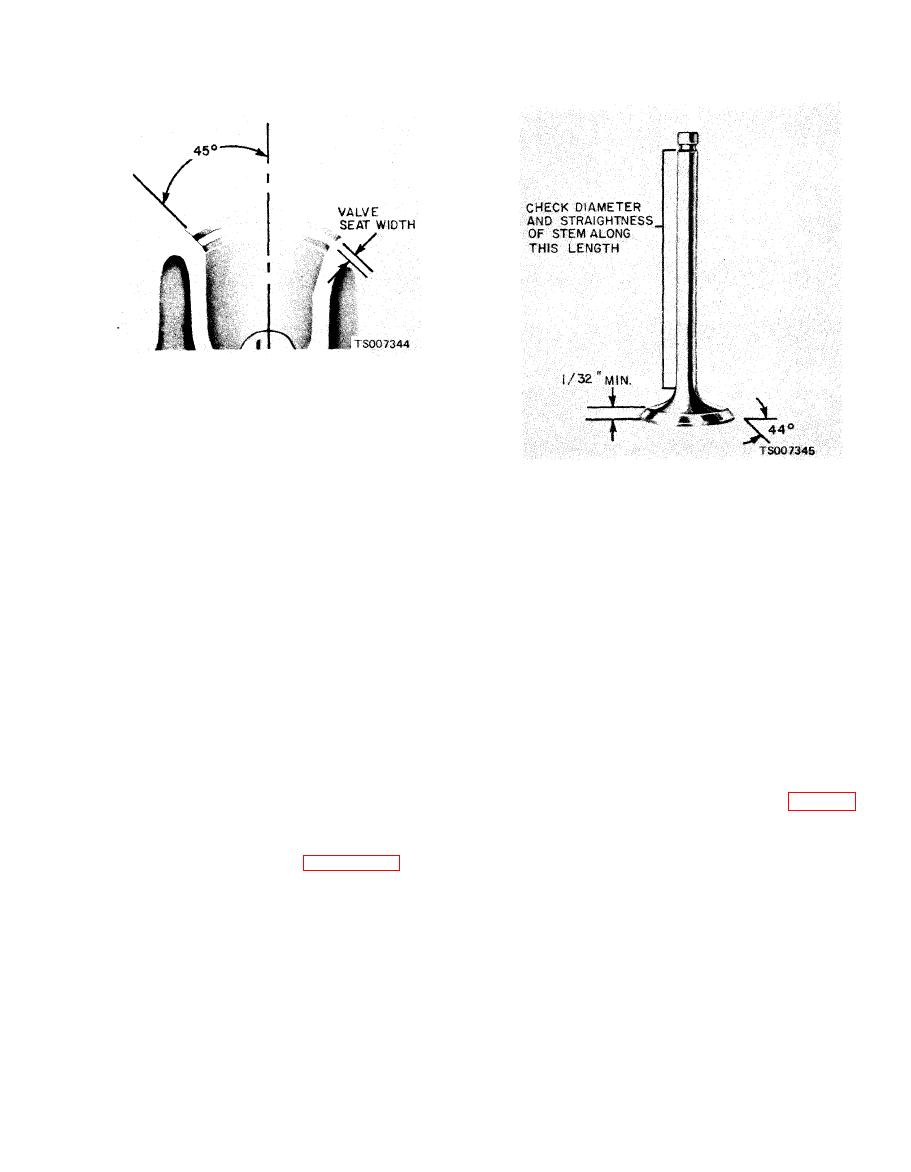

Figure 6-15. Value Seat Refacing. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(2) If the valve seat width exceeds the

maximum limit, remove enough stock from the

top edge and/or bottom edge of the seat to reduce

the width to specifications.

(3) Use a 60 degree angle grinding wheel to

remove stock from the bottom of the seats (raise

the seats) and use a 30 degree angle wheel to

(1) Inspect the valve face and the edge of the

remove stock from the top of the seats (lower the

head for pits, grooves, or scoring.

seats).

(2) Check the stem for straightness and for

(4) The finished valve seat should contact

cracks or grooves and scoring around the lock

the approximate center of the valve face. It is

area.

good practice to determine where the valve seat

(3) Check the head of the valve for burning

contacts the face. To do this, coat the seat with

or erosion, cupping, warpage or cracks. While

Prussian blue and set the valve in place. Rotate

minor pits or grooves may be removed during

the valve with light pressure. If the blue is

r e f a c i n g , badly damaged valves should be

transferred to the center of the valve face, the

replaced.

contact is satisfactory. If the blue is transferred

(4) Check the valve face runout. It should

to the top edge of the valve face, lower the valve

not exceed the specified wear limit. If the runout

exceeds 0.002 inches, the valve should be replaced

seat. If the blue is transferred to the bottom edge

of the valve face, raise the valve seat.

or refaced.

(5) Check the valve stem to valve guide

6-17. Valve Cleaning and Inspection

clearance of each valve in its respective valve

a. Cleaning. Remove carbon deposits and

guide with a dial indicator as shown in figure 6-

sludge or varnish formation from valve stems,

17. Use a flat end indicator point. Clearance

seat, and faces with a fine wire brush or buffing

should not exceed 0.0010 to 0.0027 for new

wheel.

valves. Maximum wear limit for valves in service

b. Inspection. Refer to figure 6-16 for all

is 0.0055.

inspection and measurement points, and proceed

as follows:

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |