|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-34

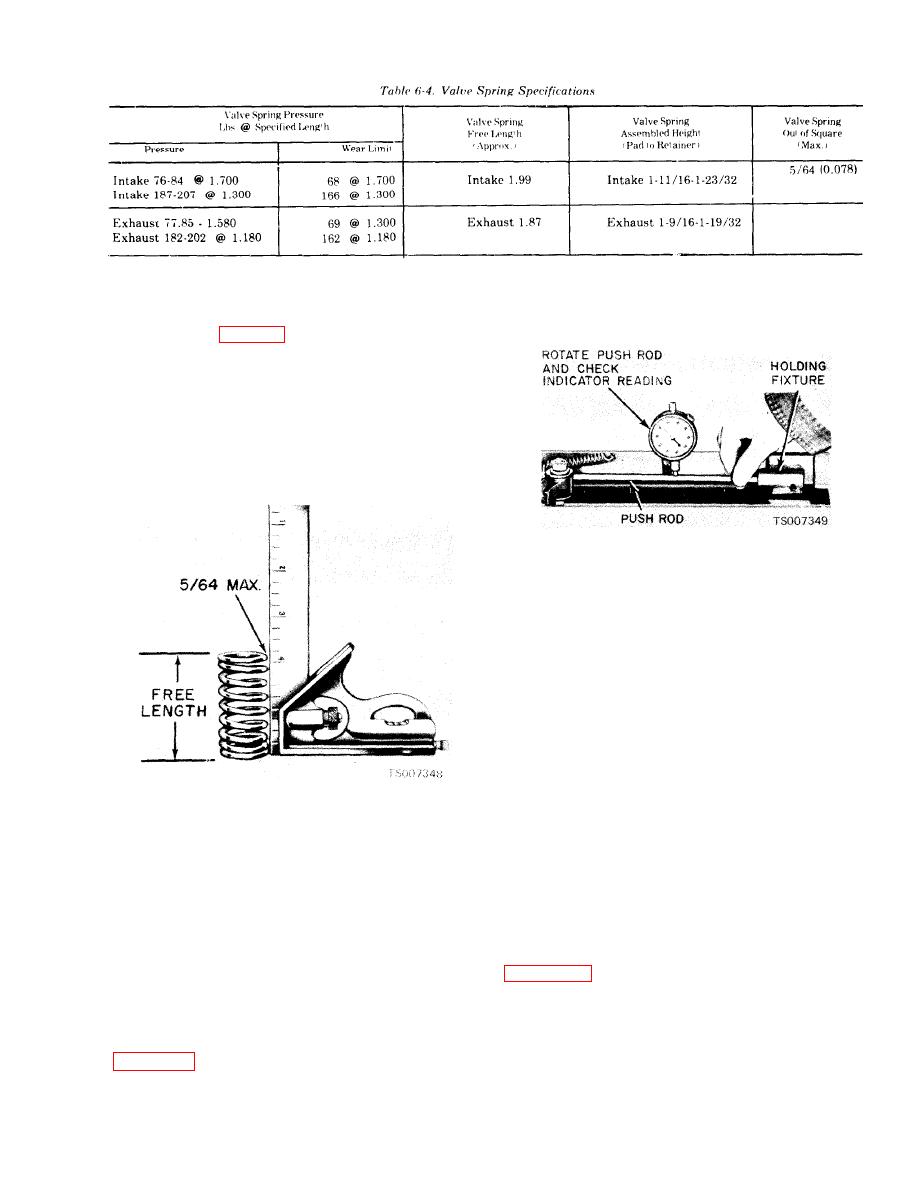

b. Valve Spring Squareness. Check each

spring for squareness using a steel square and a

surface plate (fig. 6-19). Stand the spring and

square on end on the surface plate. Slide the

spring up to the square. Rotate the spring slowly

and observe the space between the top coil of the

spring and square. If the spring is out of square

more than 5/64 inch, replace it. Follow the same

procedure to check new valve springs before

installation.

c. Hydraulic Lifter Cleaning. Clean the lifters

thoroughly in a bath of clean solvent, Federal

Specification P-D-680. Dry with a clean, lint-free

cloth.

NOTE

The valve lifter assemblies should be kept in proper

sequence so that they can be installed in their

original position. Inspect and test each lifter

separately so as not to intermix the internal parts. If

any part of the lifter assembly needs replacing,

replace the entire assembly.

d. Hydraulic Lifter Inspection.

(1) Inspect the parts and discard the entire

lifter assembly if any part shows pitting, scoring,

galling or evidence of non-rotation. Replace the

a. Pushrod Cleaning.

entire assembly if the plunger is not free in the

(1) Clean pushrods by scrubbing with

body. The plunger should drop to the bottom of

solvent, Federal Specification P-D-680.

the body by its own weight when assembled dry.

(2) Blow out the oil passage through the rod

(2) Assemble the lifter assembly and check

with compressed air.

for freeness of operation by pressing down on the

b. Pushrod Inspection.

pushrod cup. The lifters can also be checked with

(1) Check the ends of the pushrods for nicks,

a hydraulic tester to test the leak-down rate. See

grooves, roughness or excessive wear.

(2) The pushrods can be visually checked for

straightness while they are installed in the engine

by rotating them with the valve closed. They also

can be checked with a dial indicator as shown in

inches.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |