|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-12

c. Breaker Points. Check points for pitting,

spark plugs, grasp, twist, and pull on the

burning or excessive metal transfer as outlined in

moulded cap only. Do not pull on the wire because

the following steps:

the wire connections inside the cap may become

(1) The normal color of contact points should

separated or the weather seal may be damaged.

be a light gray. If the contact point surfaces are

b. Removal. Disconnect wires at plugs and at

black, it is usually caused by oil vapor, or grease

the distributor cap. Remove coil high tension

from the cam. If they are blue, the cause is

lead.

u s u a l l y excessive heating due to improper

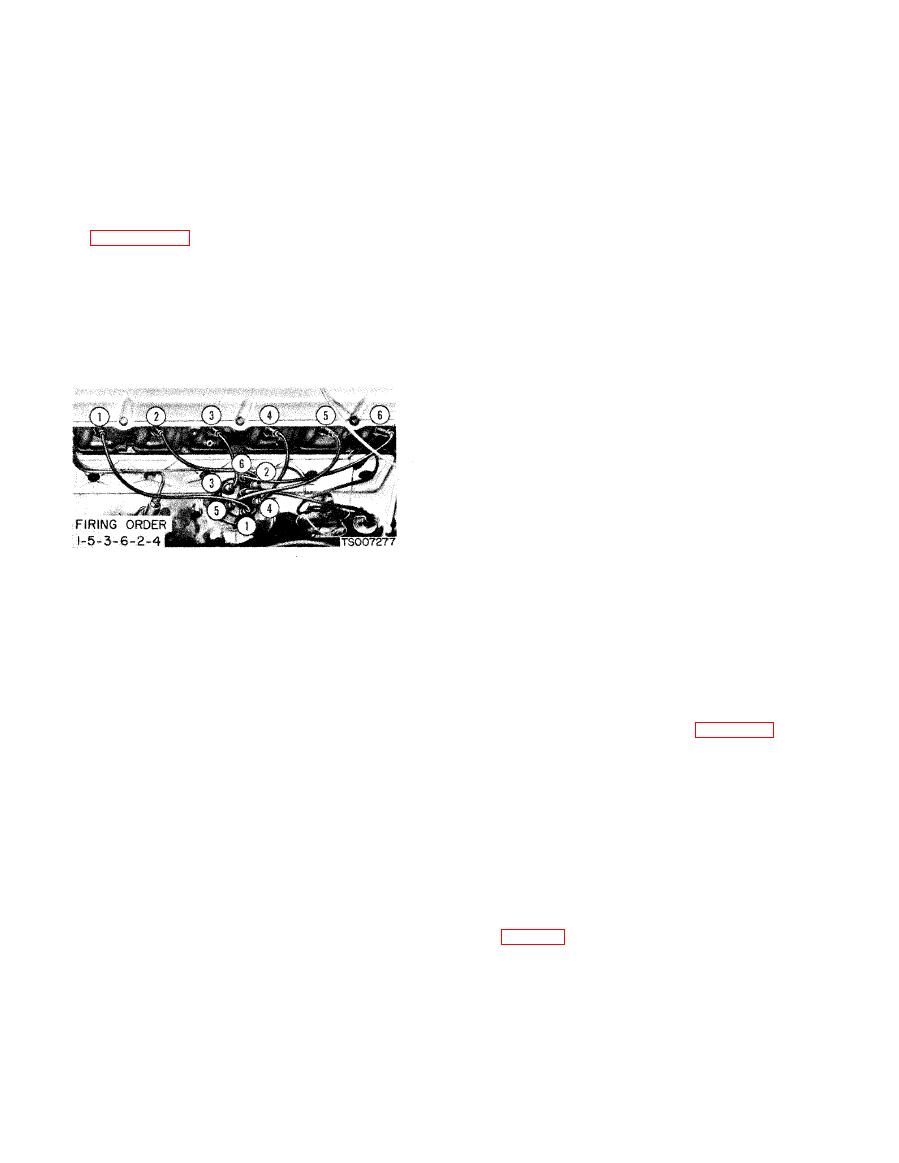

c. Installation, Connect wires to proper plugs

alignment, high resistance or open condenser

(see figure 4-10). Insert ends of wires in the

circuit.

correct sockets in distributor cap. Be sure wires

(2) Badly pitted points may be caused by a

are all the way down into their sockets and that

defective or improper condenser capacity. If the

they are held firmly in position. The No. 1 plug is

c o n d e n s e r capacity is too high, the crater

the front plug. Install wires into distributor

sockets in a clockwise direction, starting at No. 1

(depression) will form in the positive contact. If

the condenser capacity is too low, the crater will

socket. NOW install coil high tension lead. Push

form m the negative contact.

all weather seals into position.

(3) For a temporary repair, dress the contact

points with a few even strokes using a clean fine-

cut contact file. Do not attempt to remove all

roughness or dress the point surfaces down

smooth.

CAUTION

Never use emery cloth or sandpaper to

clean points as particles will be imbedded

in the points and cause arcing and rapid

burning.

justment

Use a dwell meter to check the contact dwell. It is

Check the coil for secure mounting. Wipe the coil

not advisable to use a feeler gage to adjust or to

with a damp cloth moistened in Stoddard type

check the gap of used breaker points because the

solvent and check for cracks in the coil case.

roughness of the points makes an accurate gap

Check coil terminals for tight connections and

reading or setting impossible. Clean the breaker

proper polarity.

points and check and adjust the alignment. Check

the contact dwell following the instructions of the

dwell meter manufacturer. See table 4-4 for

Disconnect spark plug wiring at the distributor

proper setting.

cap. Remove distributor cap and make the

following inspection:

a. Distributor Cap. Clean the distributor cap

The vented-type breaker points must be ac-

with a soft bristle brush and Solvent, Federal

curately aligned in order to realize the full ad-

Specification P-D-680. Dry the cap with com-

vantages provided by this design, and to assure

pressed air. Inspect the cap for cracks, burned

normal breaker point life. Any misalignment of

contacts, permanent carbon tracks or dirt or

the breaker point surfaces will cause premature

corrosion in the sockets. Replace the cap if it is

wear, overheating, and pitting.

defective.

a. Turn the distributor cam so that the breaker

b. Rotor. Clean the rotor with a soft bristle

points are closed and check the alignment of the

brush and a Stoddard type cleaning solvent, The

points (fig. 4-11).

rotor should be dried with compressed air. In-

spect the rotor for cracks or burning. Replace the

rotor if it is defective.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |