|

|||

|

|

|||

|

Page Title:

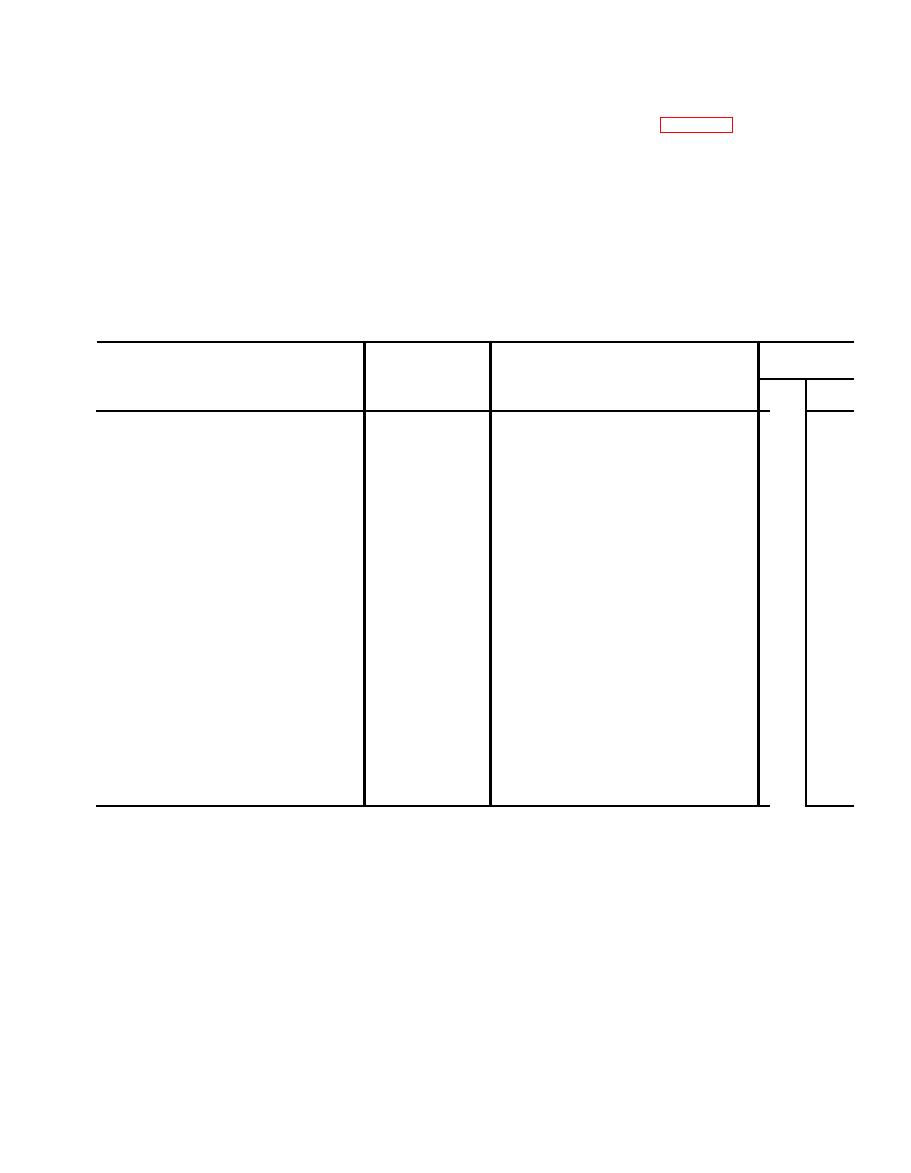

Table 4-3. Spark Plug Condition Analysis |

|

||

| ||||||||||

|

|

TM 10-3930-633-12

b. Examine firing end of plug carefully and

c. Fuel Filter. Change fuel filter element if it

compare findings with table 4-3. Careful analysis

has been in service over 100 hours.

of spark plug deposits can reveal a great deal

4-31. Spark Plug Check.

--

about engine operating conditions.

Under normal conditions, these spark plugs will

c. Remove carbon and other deposits from the

give long life performance with the normal

threads with a stiff wire brush. Any deposits will

maintenance listed in this manual. The spark

retard the heat-flow from the plug to the cylinder

plugs should be cleaned, tested and gapped at the

head, causing spark plug overheating and pre-

recommended intervals.

ignition.

a. Loosen the spark plugs one full turn, then

blow any accumulation of dirt out of the spark

plug wells before completing the removal.

Service

procedure

Clean &

Plug

Condition

regap

Replace

Cause

Light tan or gray deposits on firing tip

X

Normal

Normal use and engine condition

x

Black, dry fluffy carbon deposits on in-

Too cold a plug, weak ignition, dirty air

Carbon fouled

sulator tips, exposed shell surfaces and

cleaner, defective fuel pump, too rich a

fuel mixture, improperly operating heat

electrodes

riser or excessive idling

x

Excessive oil entering combustion chamber

`Wet, black deposits on the insulator. shell

Oil fouled

through worn rings and pistons, excessive

bore and electrodes

clearance between valve guides and

stems, or worn or loose bearings

x

Dark gray, black, yellow or tan deposits or

Lead fouled

Highly leaded gasoline

a fused glazed coating on the insulator tip

x

Deposits built up, closing gap between

Excessive oil or carbon fouling

Gap bridged

electrodes

x

Severely worn or eroded electrodes

Worn

Caused by severe service and not servicing

plugs at proper intervals

x

Sudden acceleration

Melted or spotty deposits resembling

Fused spot deposit

bubbles or blisters on electrode and in-

sulator

x

White or light gray insulator with small

Overheating

Engine overheating. Wrong type of fuel,

loose spark plugs, too hot a plug, low fuel

black or gray brown spots and with

pump pressure or incorrect ignition

bluish-burnt appearance of electrodes

timing.

x

Engine overheating. Wrong type of fuel,

Melted electrodes and possibly blistered

Preignition

incorrect ignition timing or advance. Too

insulator, metallic deposits on insulator

hot a plug, burnt valves or engine

indicate engine damage

overheating.

wire-type gage to check the gap. If old spark

d. Clean any heavy carbon deposits from

plugs are reused, install with new gaskets.

the inside of the plugs with a thin-bladed knife,

Torque to 30 ft/lbs.

then finish cleaning them with an abrasive-type

cleaner. Use the cleaner sparingly, as excessive

NOTE

Do not overtighten spark plugs, the gap may

abrasive blasting may damage the porcelain

change considerably due to distortion of the plug

around the center electrode. If the porcelain is

outer shell, or the insulator may be cracked.

badly glazed or eroded, replace the spark plugs.

e. After cleaning, examine the plug carefully

for cracked or broken insulator, badly eroded

Whenever an examination of the high tension

electrodes and other signs of failure. Replace as

wiring reveals cracks, chafed areas, burned in-

required.

sulation or other deterioration, the wiring set

f. Clean the electrode surfaces with a small file.

should be replaced. Such poor insulation leads to

Dress the electrodes to secure flat parallel sur-

rapid spark plug fouling and misfiring due to

faces on both the center and side electrode.

current leakage.

g. Adjust the spark plug gap to 0.035 inch, by

a. General. When removing the wires from the

bending only the outside electrode. Use a round

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |