|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-12

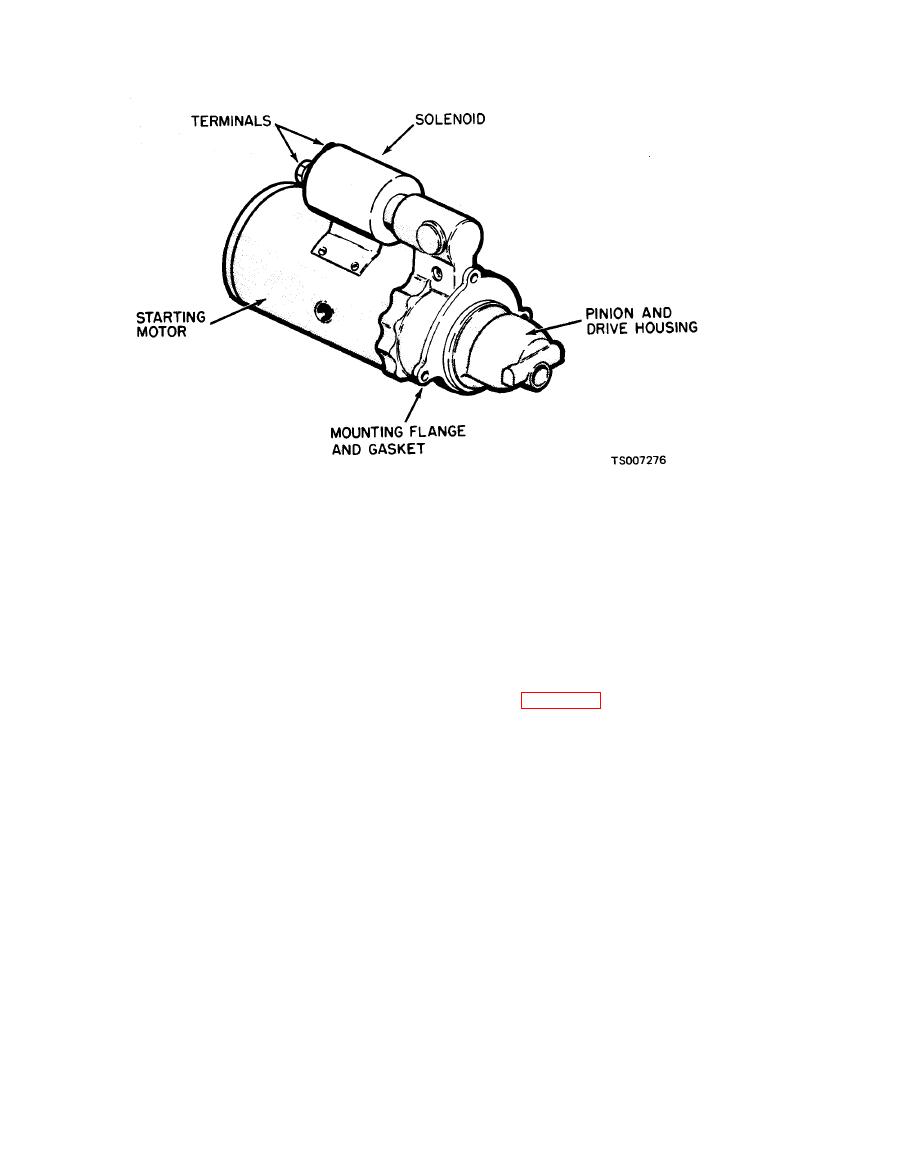

d. Installation.

b. Testing.

(1) Position the starting motor against the

(1) Use a battery known to be in good

flywheel housing so that mounting holes line up

condition and an accurate voltmeter. Connect the

and install three mounting bolts. Torque bolts to

positive lead of the voltmeter to the positive

12-15 ft/lbs. Use of a new gasket when installing

terminal of the battery, and the negative lead to

motor is advised.

the negative (grounded) terminal of the battery.

(2) Connect the battery cable to the battery

Record the voltage reading.

and to the starting motor. Connect wiring as

(2) Pull the high tension lead from the

shown in figure 4-7.

ignition coil to prevent the engine from starting

(3) Check the operation of the starting

during the starting motor test.

motor. Make sure it cranks the engine as

(3) Connect the positive lead of the volt-

required.

meter to ground and the negative lead of the

voltmeter to starter switch terminal. Turn and

hold the ignition switch to the start position and

Ignition tune-up is the orderly and systematic

read the voltmeter.

process of checking the engine and accessory

(4) Compare the voltmeter reading with the

equipment to maintain or restore satisfactory

previously recorded voltmeter reading. If the

engine performance. Ignition tune-up must be

voltage drop is more than 4 volts, or if the second

accomplished semi-annually (500 hours) and more

reading is less than 8 volts, the starting motor is

frequently if engine performance indicates the

probably faulty.

need for these services. Perform ignition tune-up

c. Removal.

as outlined in the following paragraphs after

(1) Disconnect the positive battery cable

checking the following items:

from the battery.

a. Air Cleaner. Be sure air cleaner has

(2) Disconnect and tag the electrical leads

received recent service and is not restricted.

from the starting motor.

b. Carburetor. Check approximate idle speed

(3) Remove the starting motor from the

and mixture adjustment. (These will have to be

flywheel housing, after removal of three mounting

readjusted after the tune-up. )

bolts. Pull straight out on the starting motor to

disengage the pinion gear from the ring gear.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |